Technical Report Summary on the Minorca Property, Minnesota, USA

Technical Report Summary on the Minorca Property, Minnesota, USA

S-K 1300 ReportCleveland-Cliffs Inc.

SLR Project No: 138.02467.00001

February 7, 2022

Effective Date: December 31, 2021

Technical Report Summary on the Minorca Property, Minnesota, USA

SLR Project No: 138.02467.00001

Prepared by

SLR International Corporation

22118 20th Ave SE, Suite G202

Bothell, WA 98021 USA

for

Cleveland-Cliffs Inc.

200 Public Square, Suite 3300

Cleveland, OH 44114

Effective Date – December 31, 2021

Signature Date – February 7, 2022

Distribution: 1 copy – Cleveland-Cliffs Inc.

1 copy – SLR International Corporation

CONTENTS

| | | | | |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

3.3 Encumbrances | 27 |

3.4 Royalties | 27 |

3.5 Other Significant Factors and Risks | 27 |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

6.2 Local Geology | 37 |

6.3 Property Geology | 45 |

6.4 Mineralization | 46 |

6.5 Deposit Types | 49 |

| |

| |

7.2 Drilling | 53 |

7.3 Hydrogeology and Geotechnical Data | 59 |

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 i

| | | | | |

| |

| |

| |

8.3 Sample Security | 79 |

8.4 Conclusions | 79 |

8.5 Recommendations | 80 |

| |

| |

9.2 Limitations | 88 |

9.3 Conclusions | 88 |

| |

| |

| |

| |

| |

| |

| 97 |

| |

| |

| |

| |

| |

| |

| |

11.11 Model Validation | 109 |

11.12 Model Reconciliation | 117 |

11.13 Mineral Resource Statement | 118 |

| |

| |

| |

| |

| |

| 127 |

| |

| |

| |

| |

| |

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 ii

| | | | | |

| |

13.6 Mining Fleet | 142 |

13.7 Mine Workforce | 142 |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

15.4 Tailings Storage Facility | 157 |

15.5 Power | 160 |

15.6 Natural Gas | 162 |

15.7 Diesel, Gasoline, and Propane | 162 |

15.8 Communications | 163 |

15.9 Water Supply | 163 |

15.10 Mine Support Facilities | 163 |

15.11 Plant Support Facilities | 164 |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 iii

TABLES

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 iv

| | | | | |

Table 6-1: Table of Lithological Units | 45 |

Table 6-2: Deposit Characteristics | 48 |

Table 7-1: Drilling Summary | 54 |

Table 7-2: Yearly Drilling Summary | 54 |

Table 7-3: Drilling as of April 24, 2021 | 59 |

| |

Table 9-1: Minorca Database Validation Observations | 85 |

| |

| |

Table 10-3: Example of Geotechnical Properties - Biwabik IF | 94 |

Table 10-4: Pellets Produced by Pit and by Size Fraction | 95 |

| |

| |

| |

| |

| 104 |

| |

| |

| |

Table 11-9: Comparative Statistics of Composites and Blocks for Key Economic Variables Base Block Model | 113 |

Table 11-10: Q3 2021 Model Reconciliation | 118 |

Table 11-11: Summary of Mineral Resource -December 31, 2021 | 118 |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 v

| | | | | |

Table 13-7: Major Mining Equipment | 142 |

| |

| |

| |

| 152 |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

FIGURES

| | | | | |

| |

Figure 3-2: Property Tenure Map | 26 |

| |

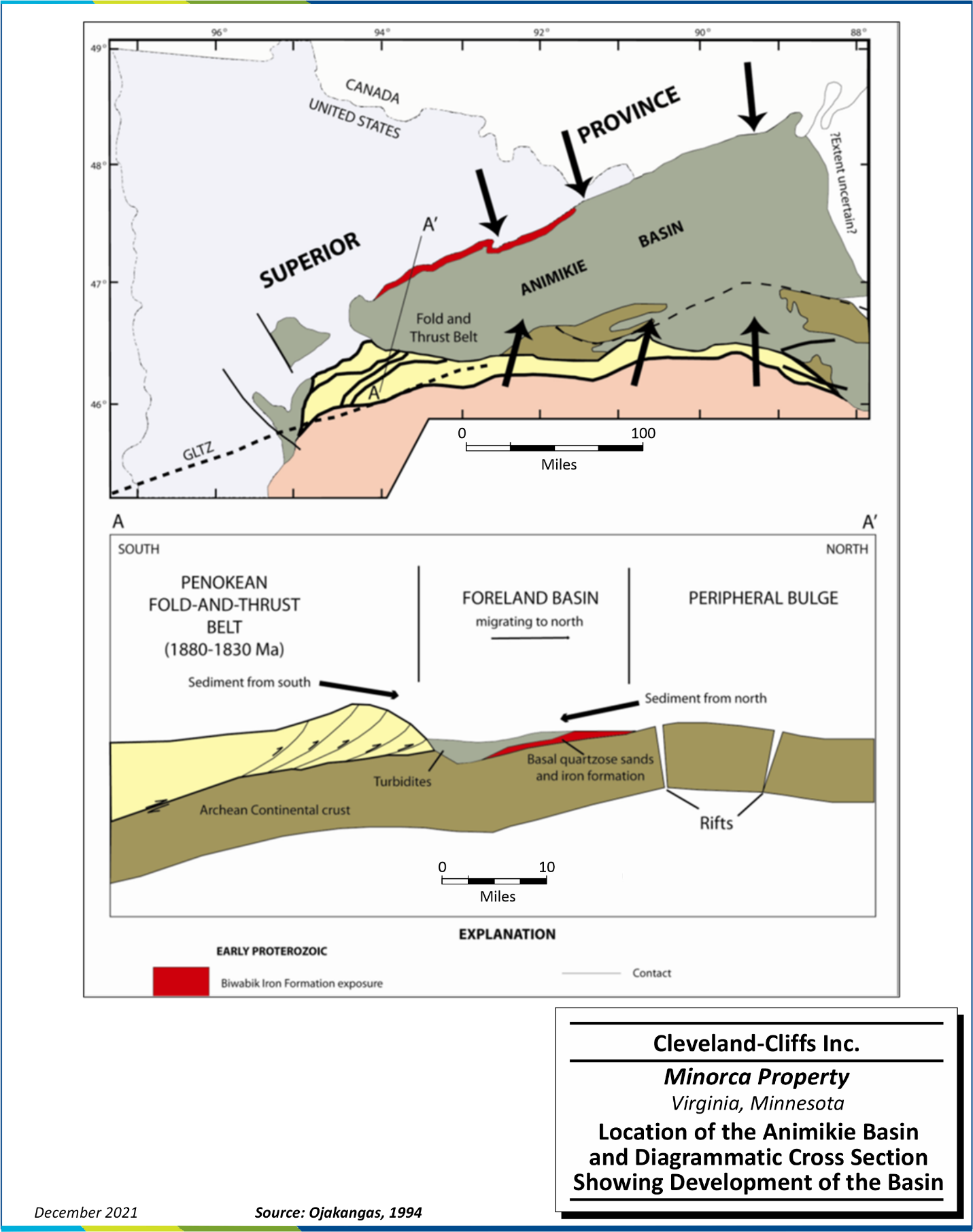

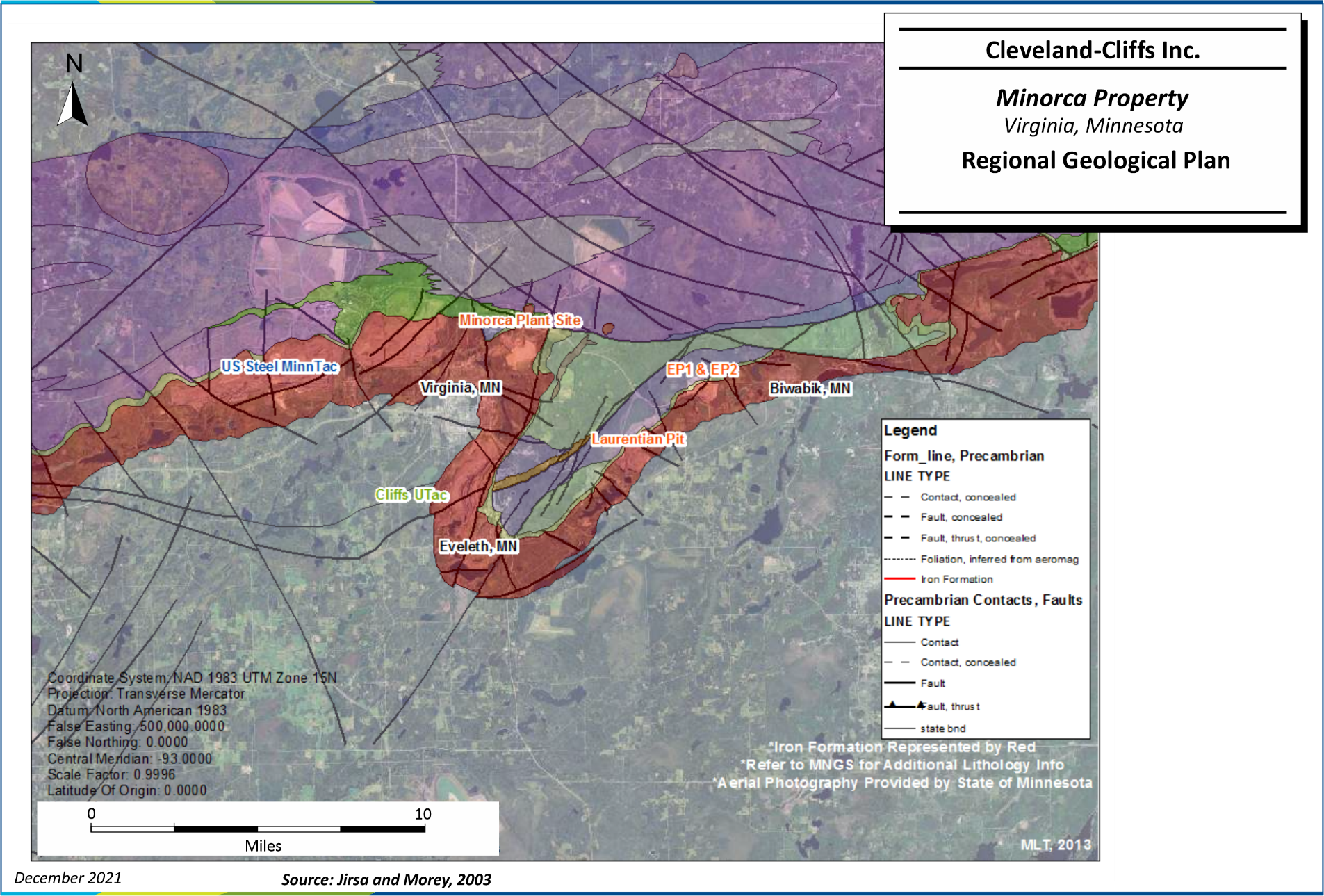

Figure 6-2: Regional Geological Plan | 36 |

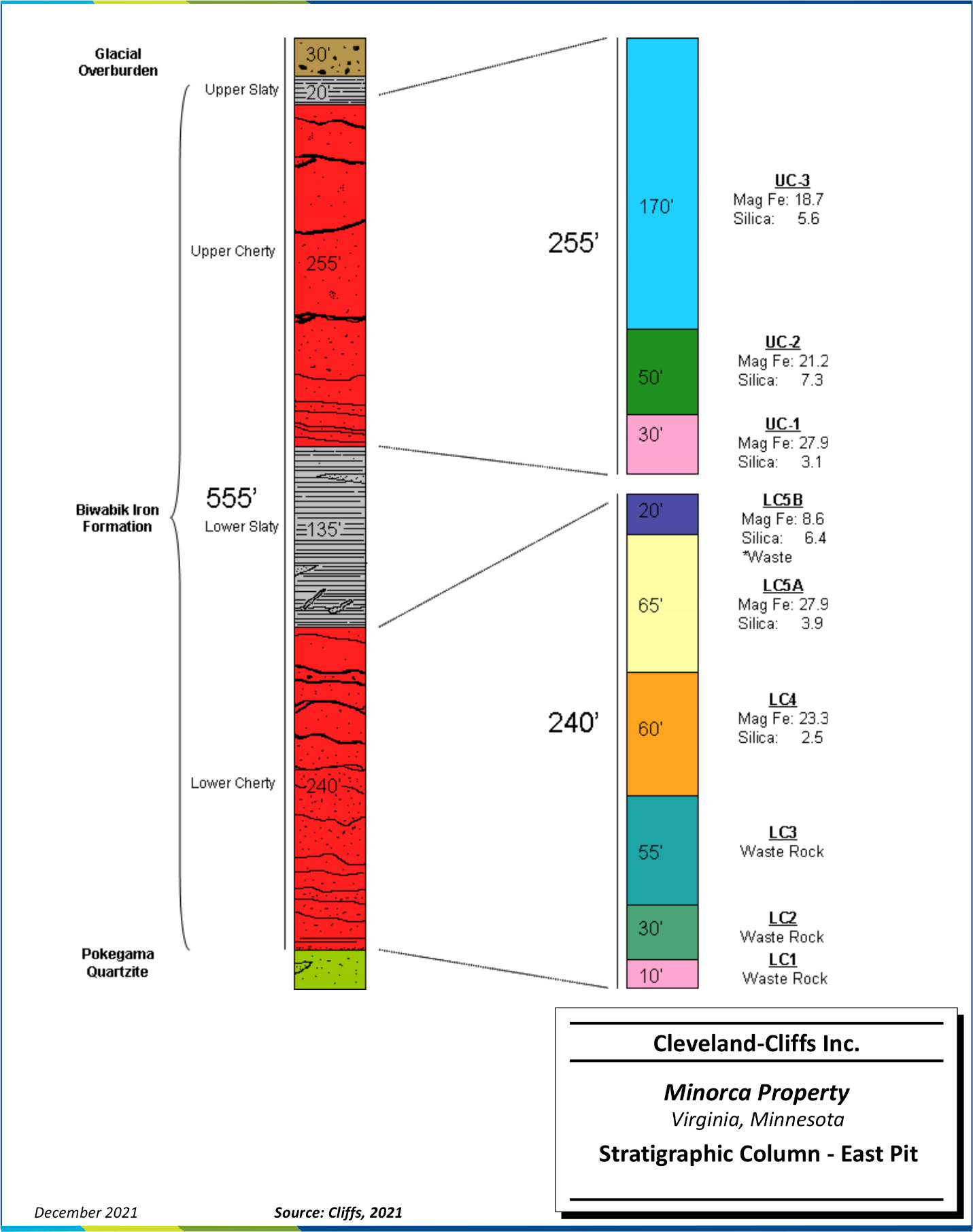

Figure 6-3: Stratigraphic Column - East Pit | 38 |

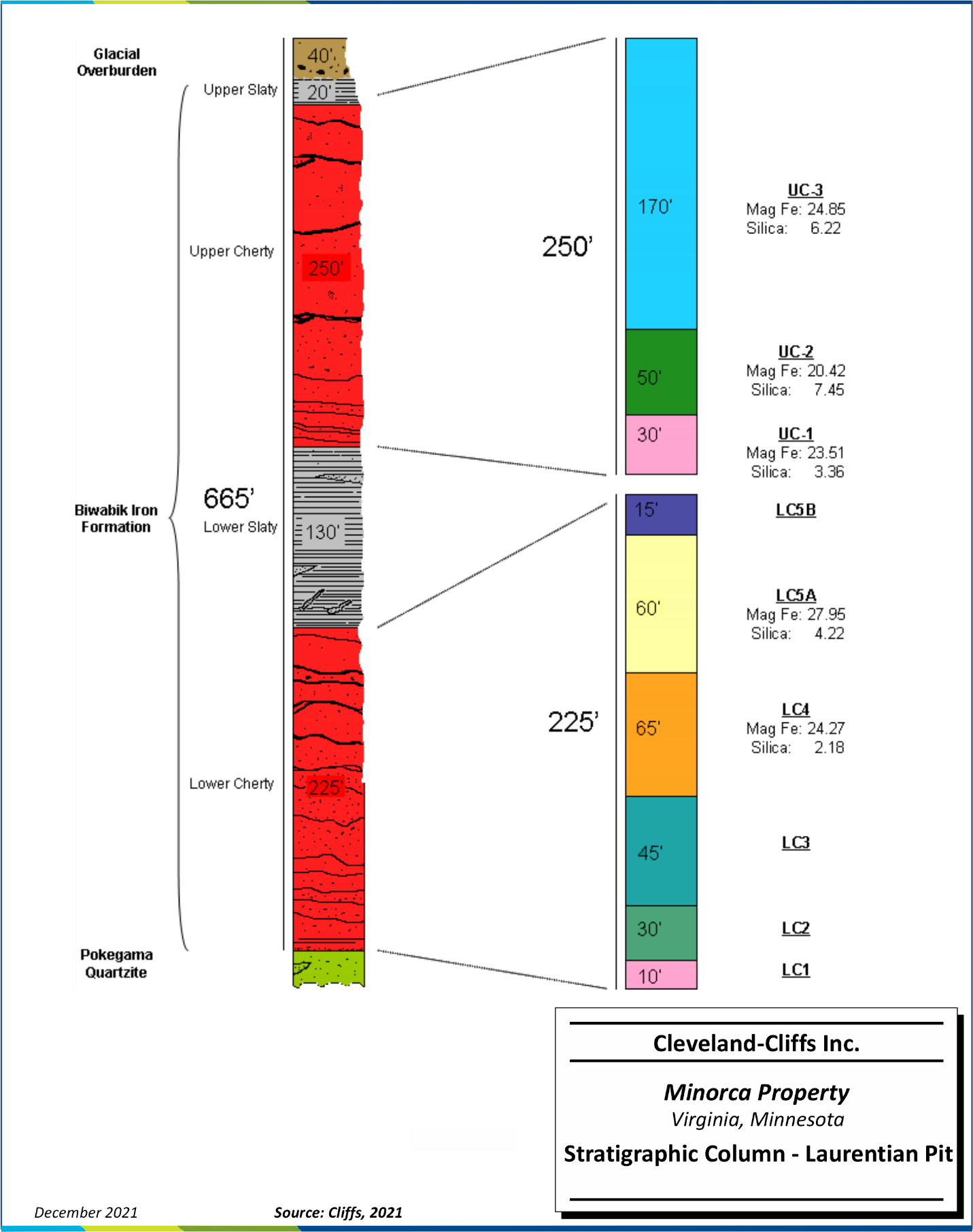

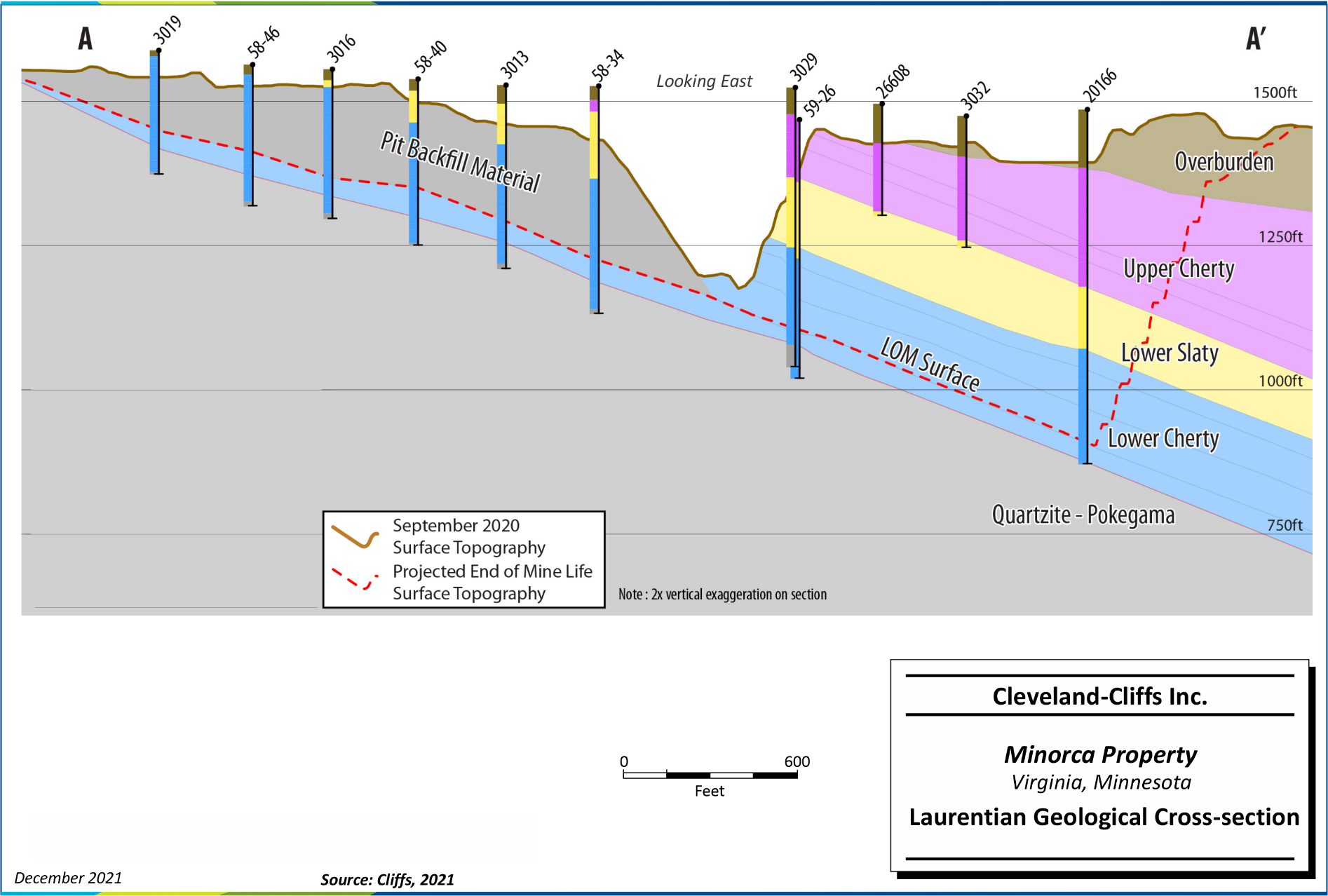

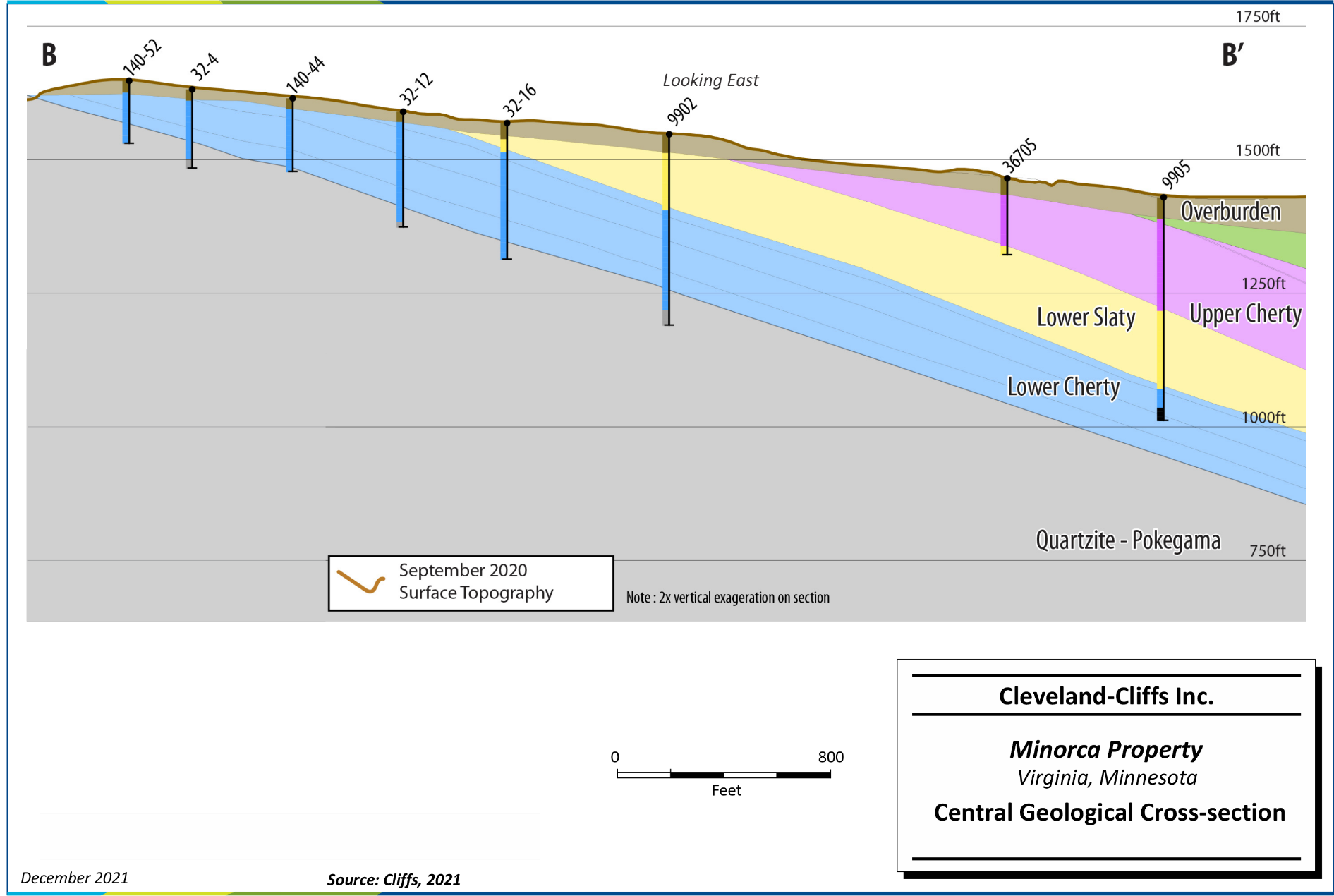

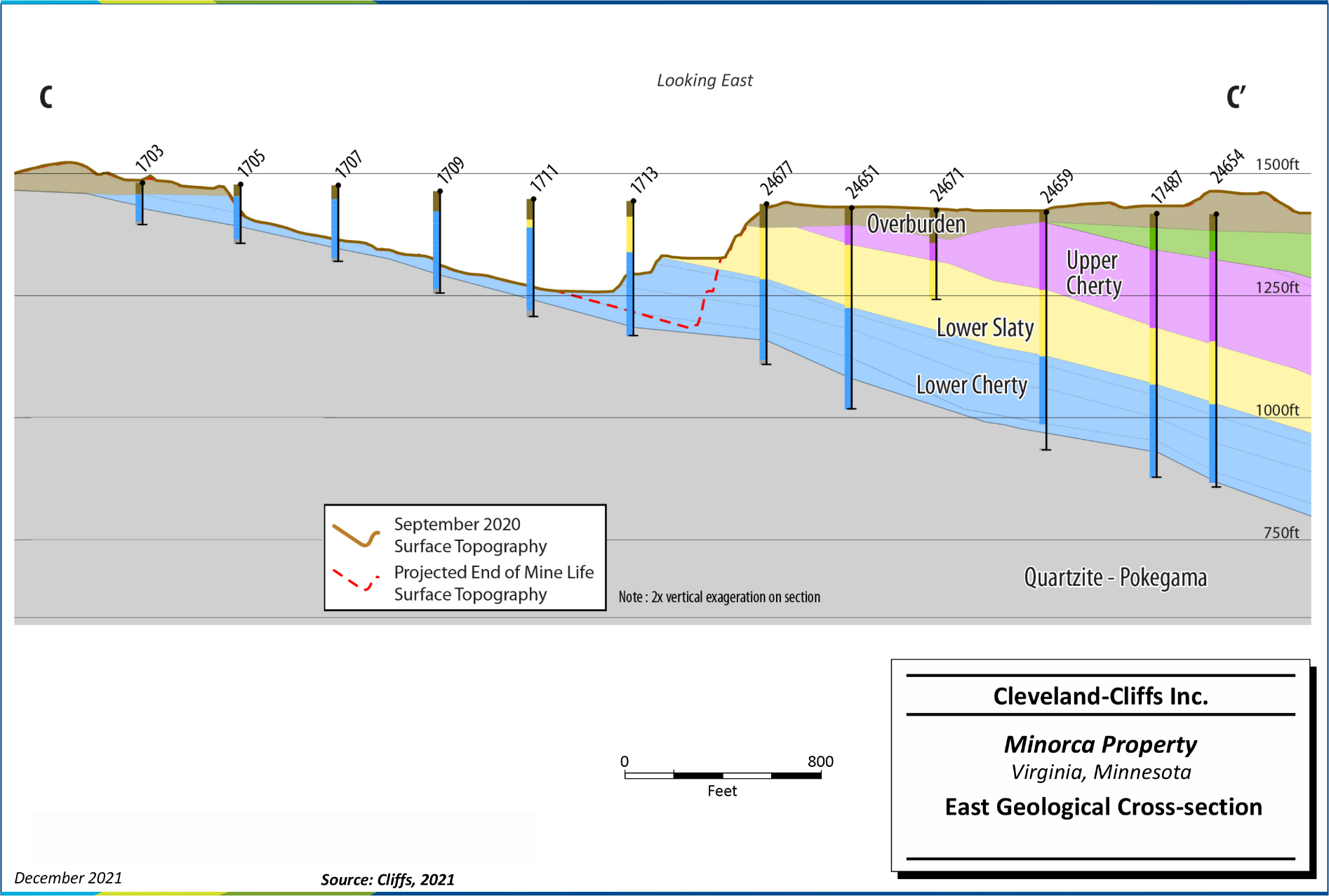

Figure 6-4: Stratigraphic Column - Laurentian Pit | 39 |

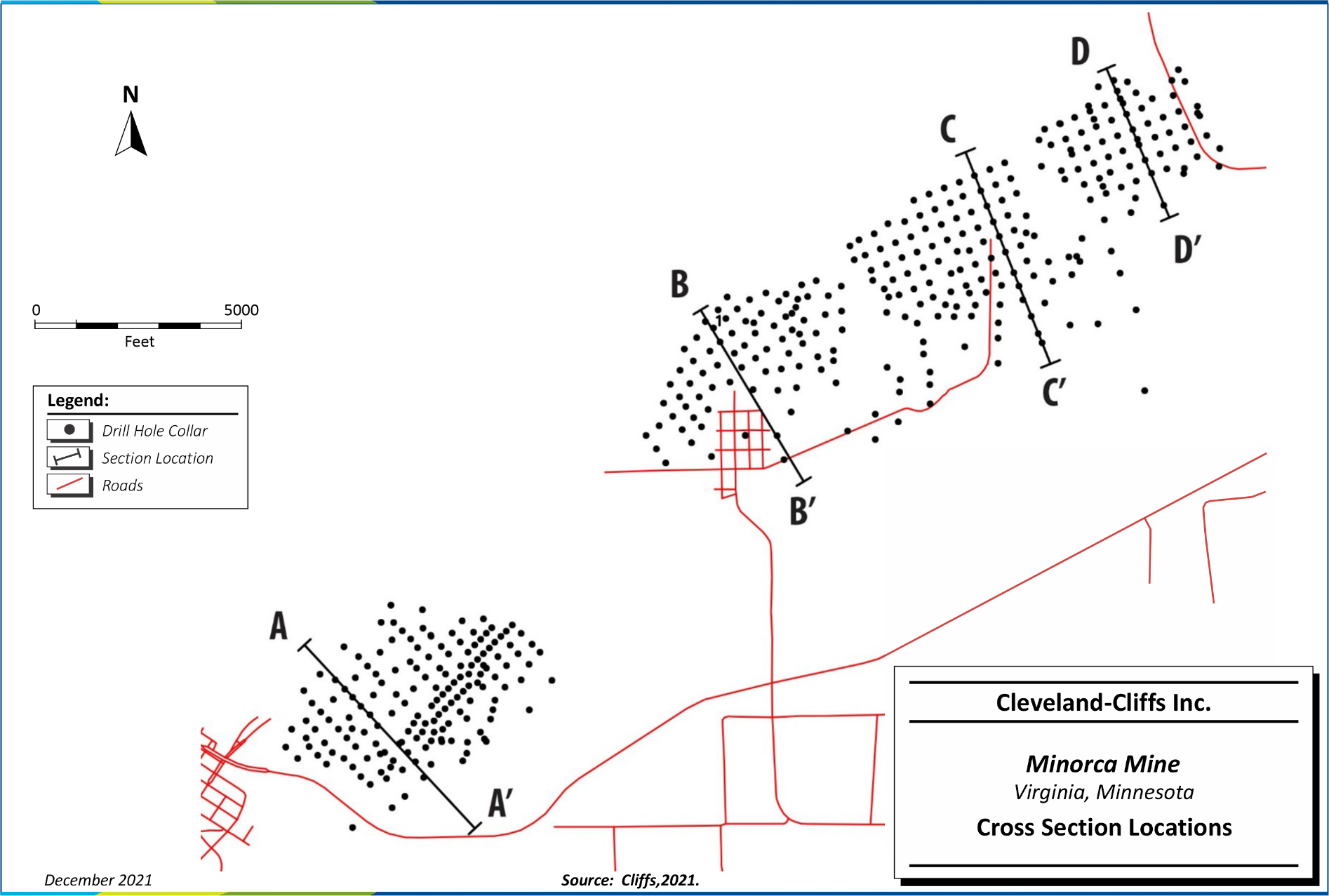

Figure 6-5: Section Plan View | 40 |

Figure 6-6: Laurentian Geological Cross-section | 41 |

Figure 6-7: Central Geological Cross-section | 42 |

Figure 6-8: East Geological Cross-section | 43 |

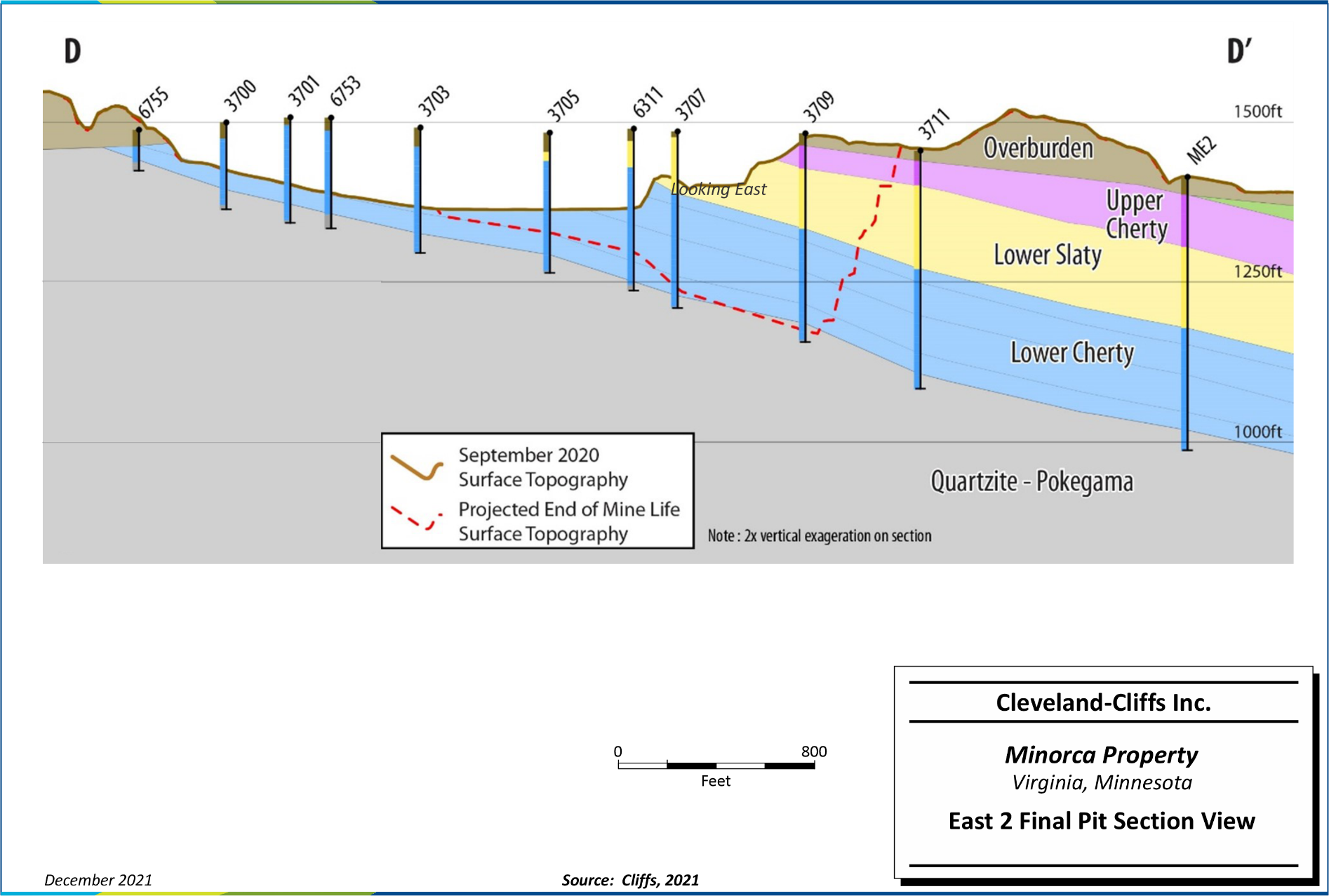

Figure 6-9: East 2 Final Pit Section View | 44 |

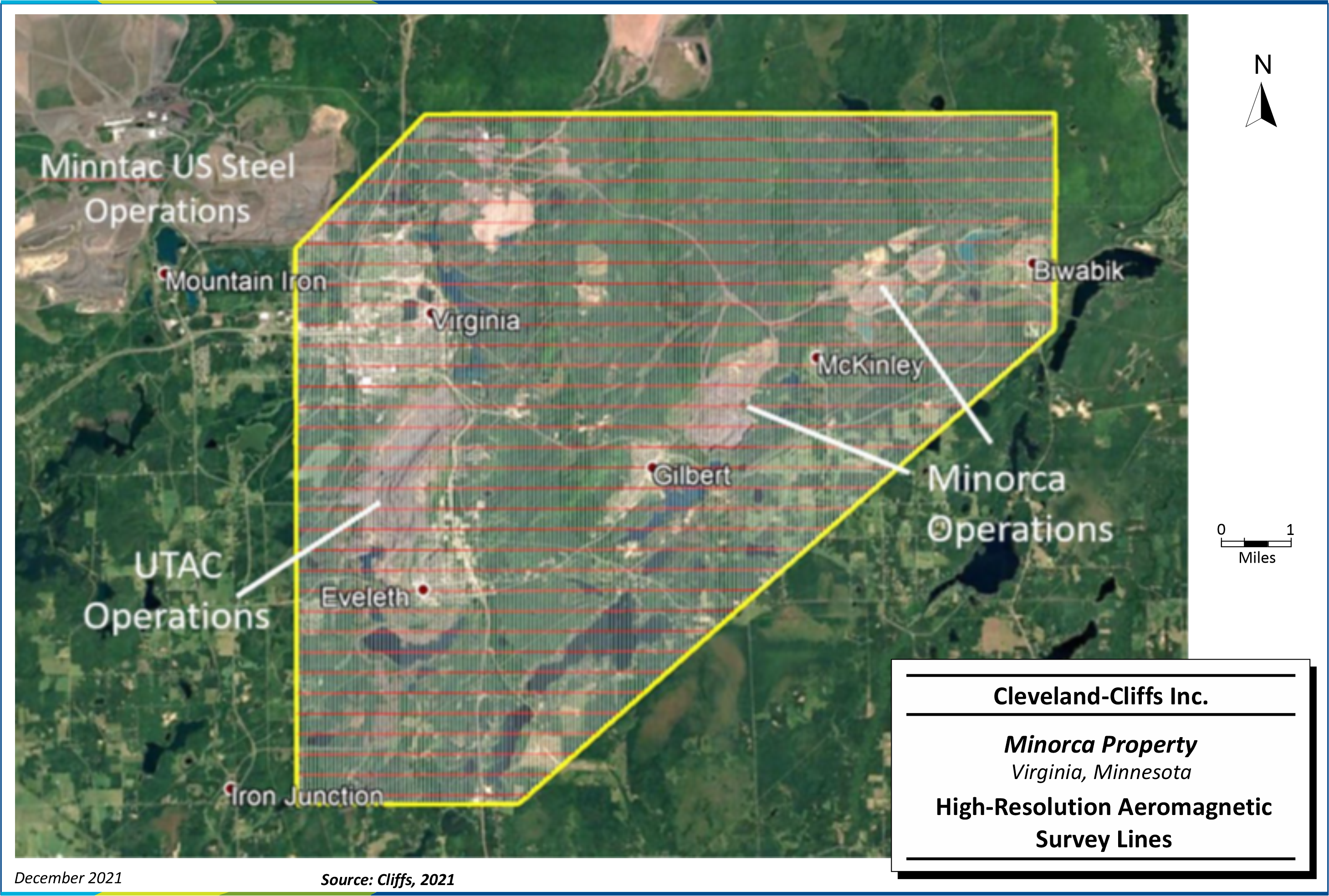

Figure 7-1: High-Resolution Aeromagnetic Survey Lines | 51 |

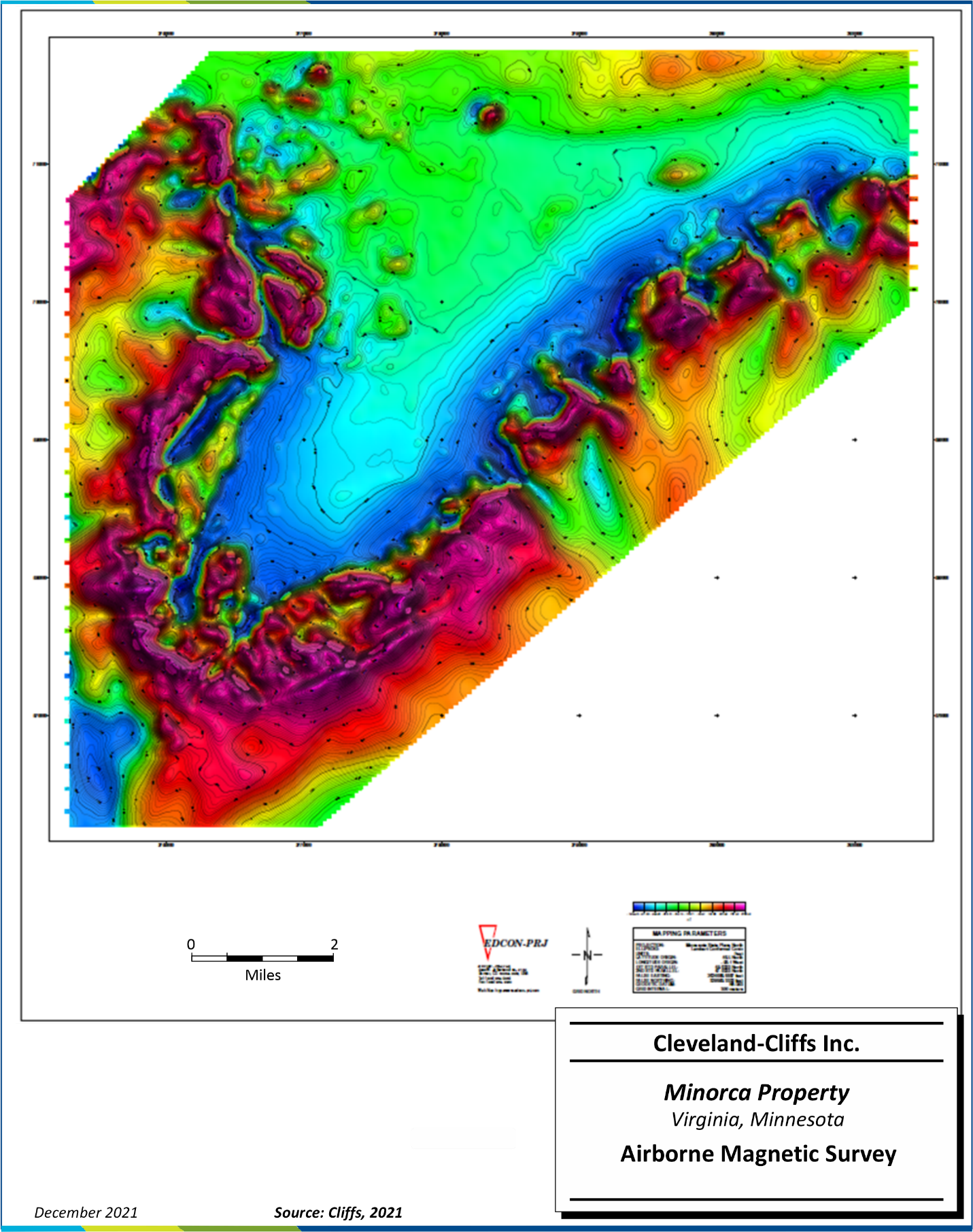

Figure 7-2: Airborne Magnetic Survey | 52 |

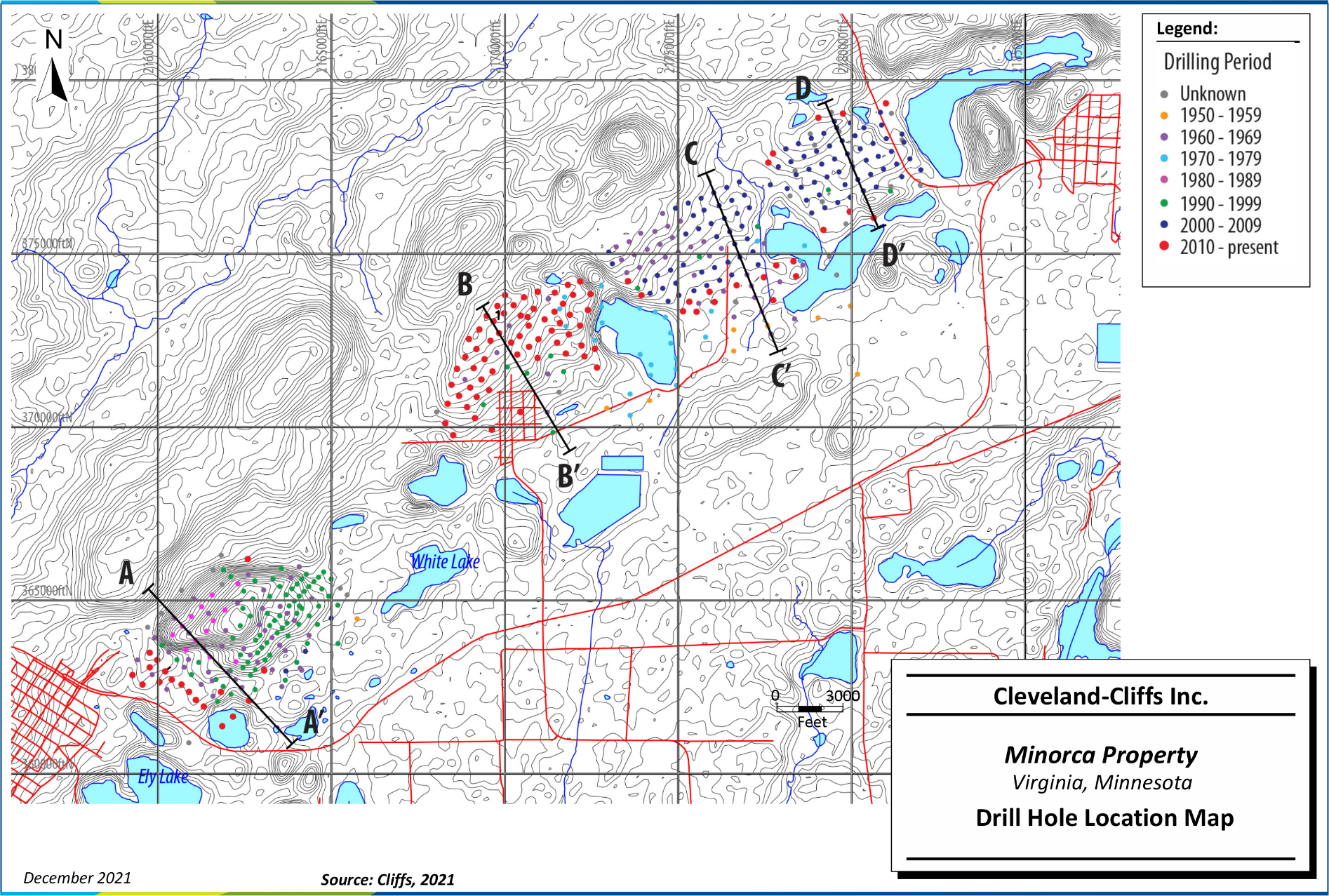

Figure 7-3: Drill Hole Location Map | 56 |

| |

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 vi

| | | | | |

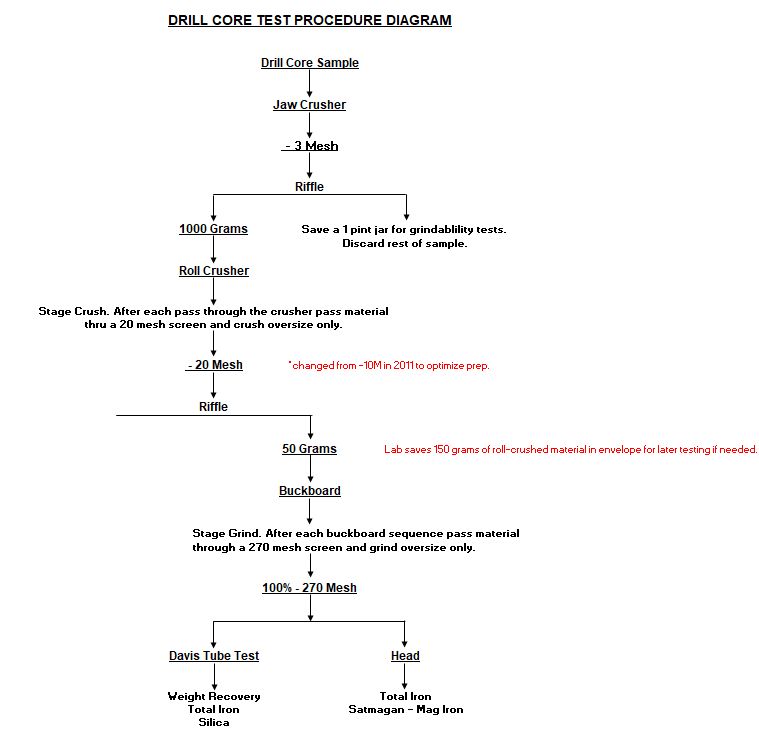

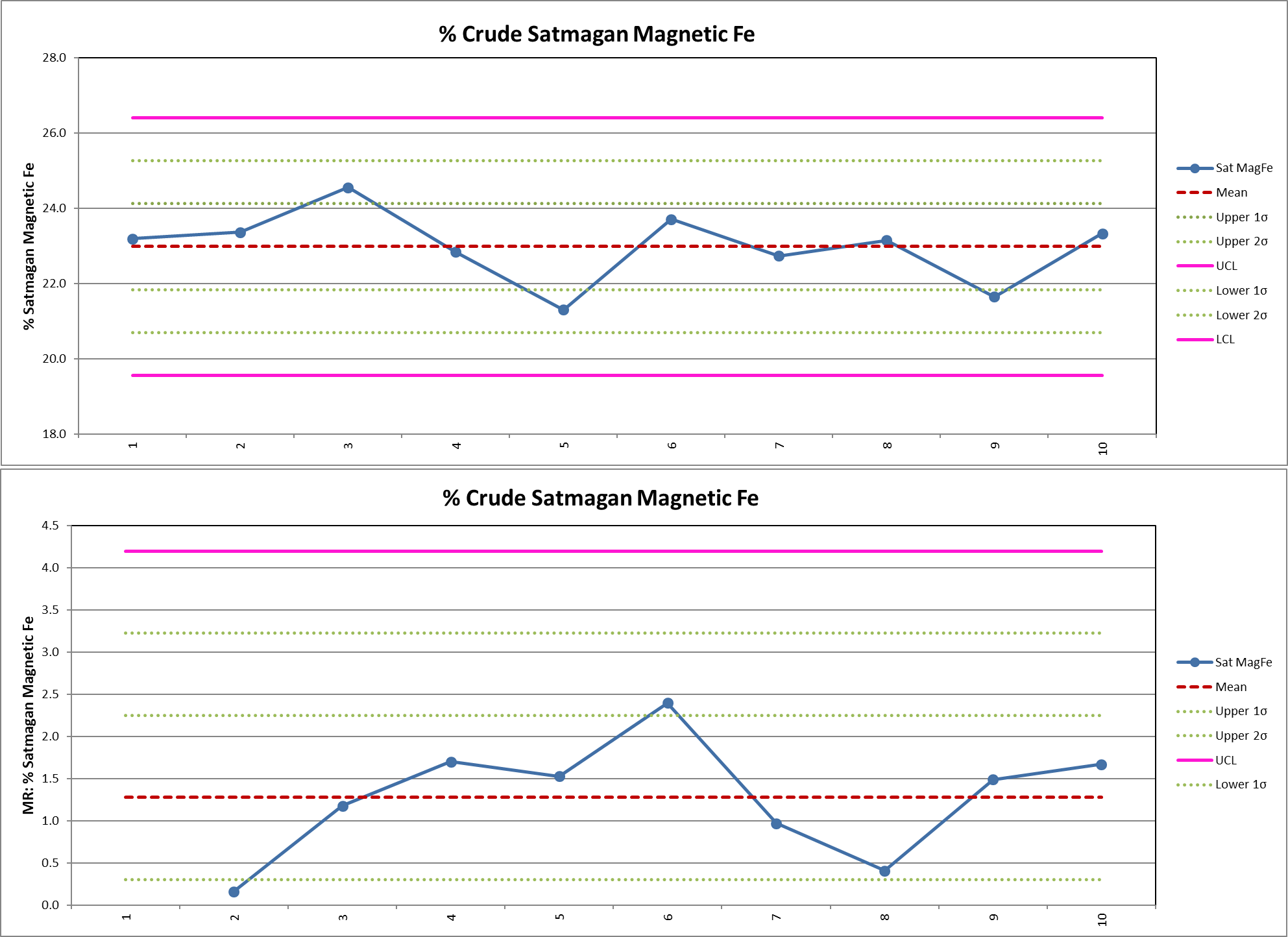

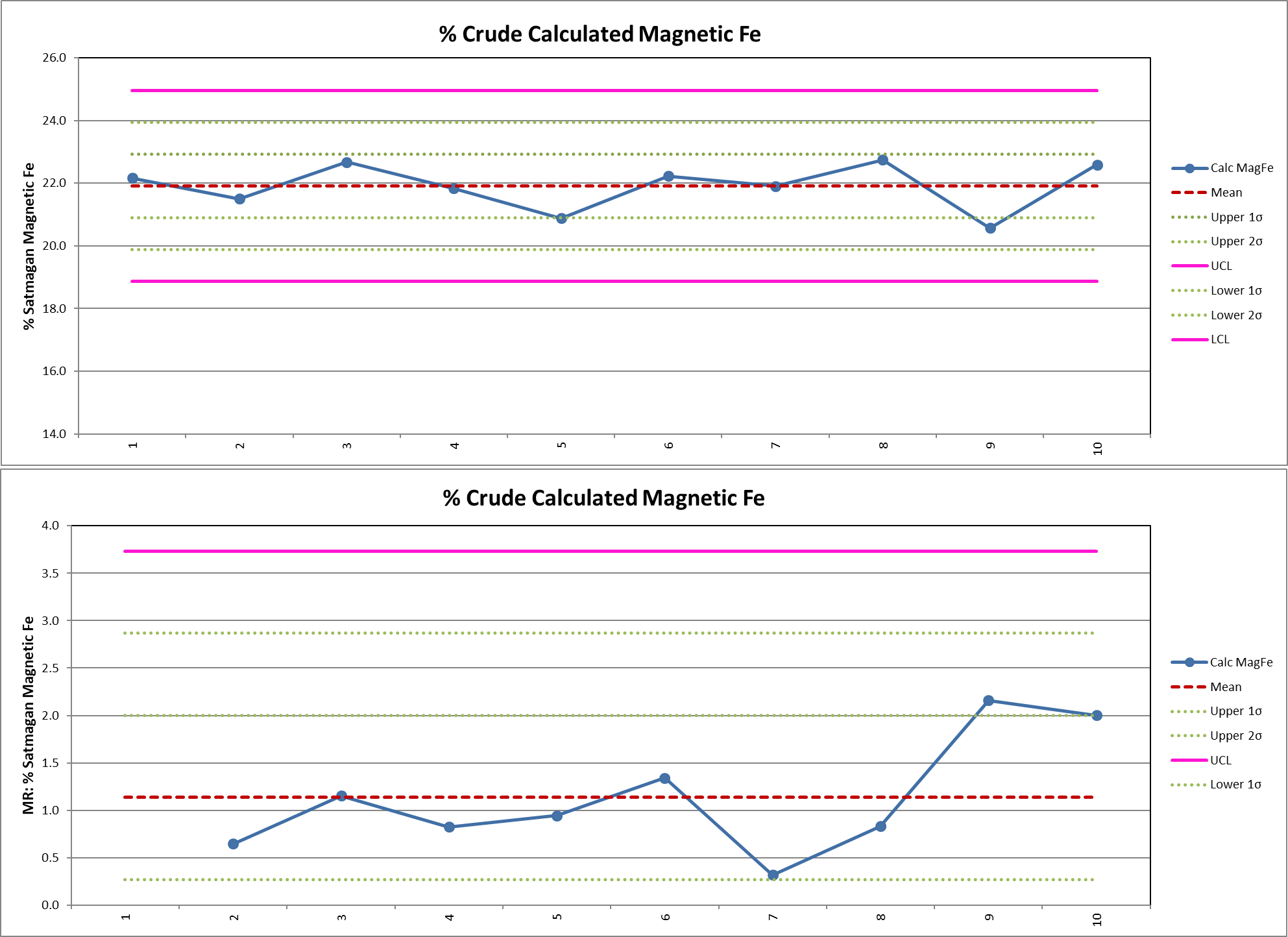

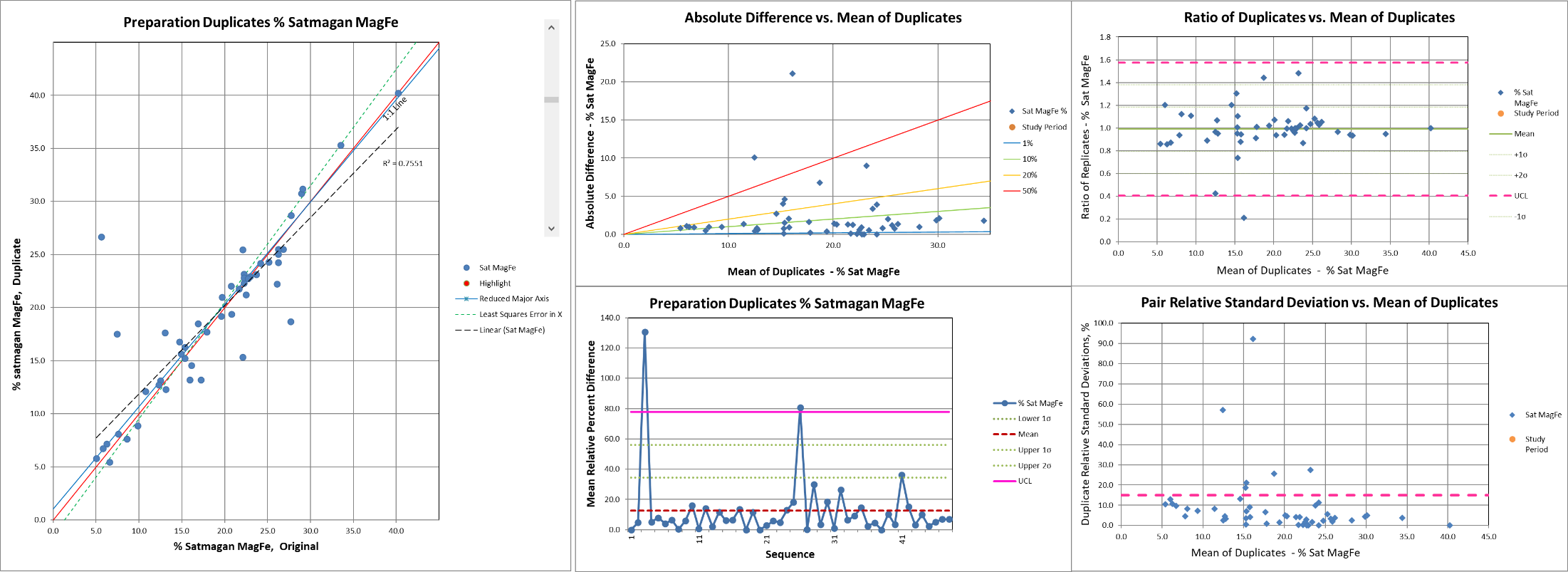

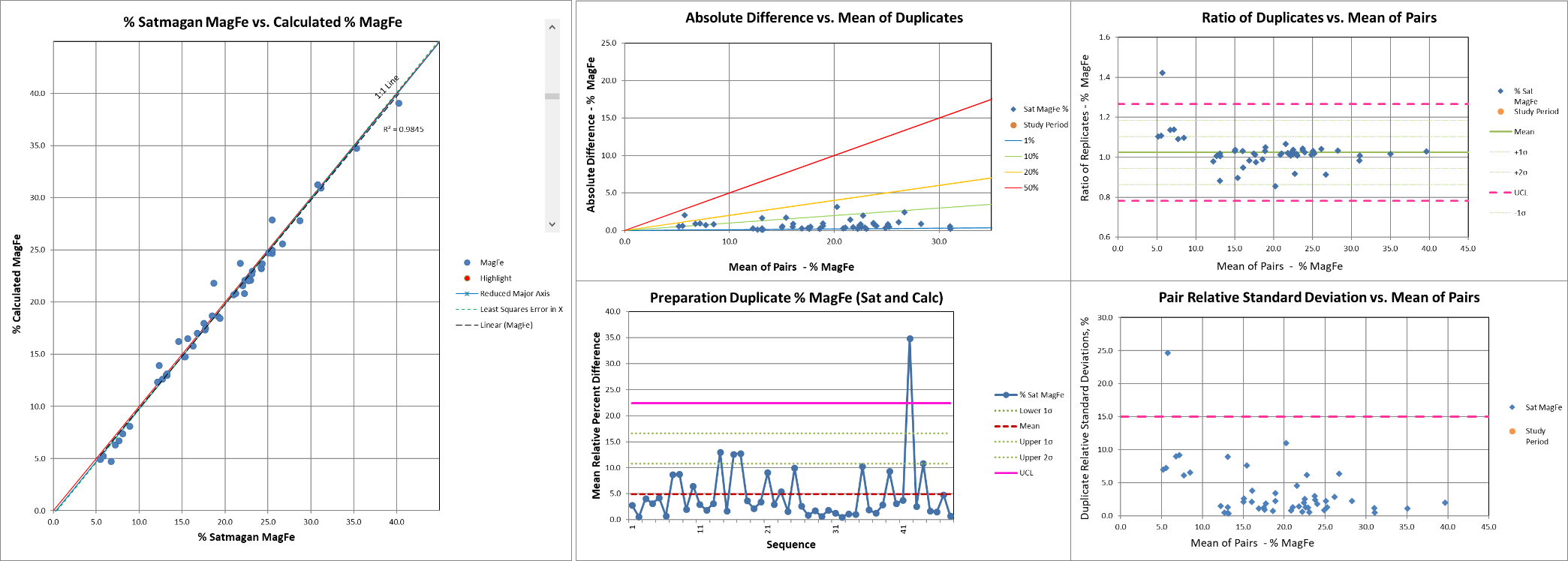

Figure 8-2: Satmagan Magnetic Iron 2021 | 66 |

Figure 8-3: Calculated Magnetic Iron 2021 | 67 |

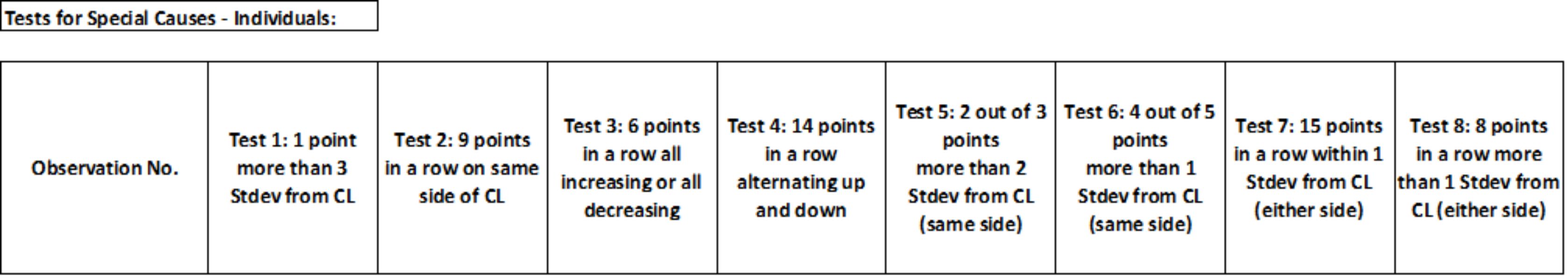

Figure 8-4: Calculated Magnetic Iron versus Satmagan 2021 | 68 |

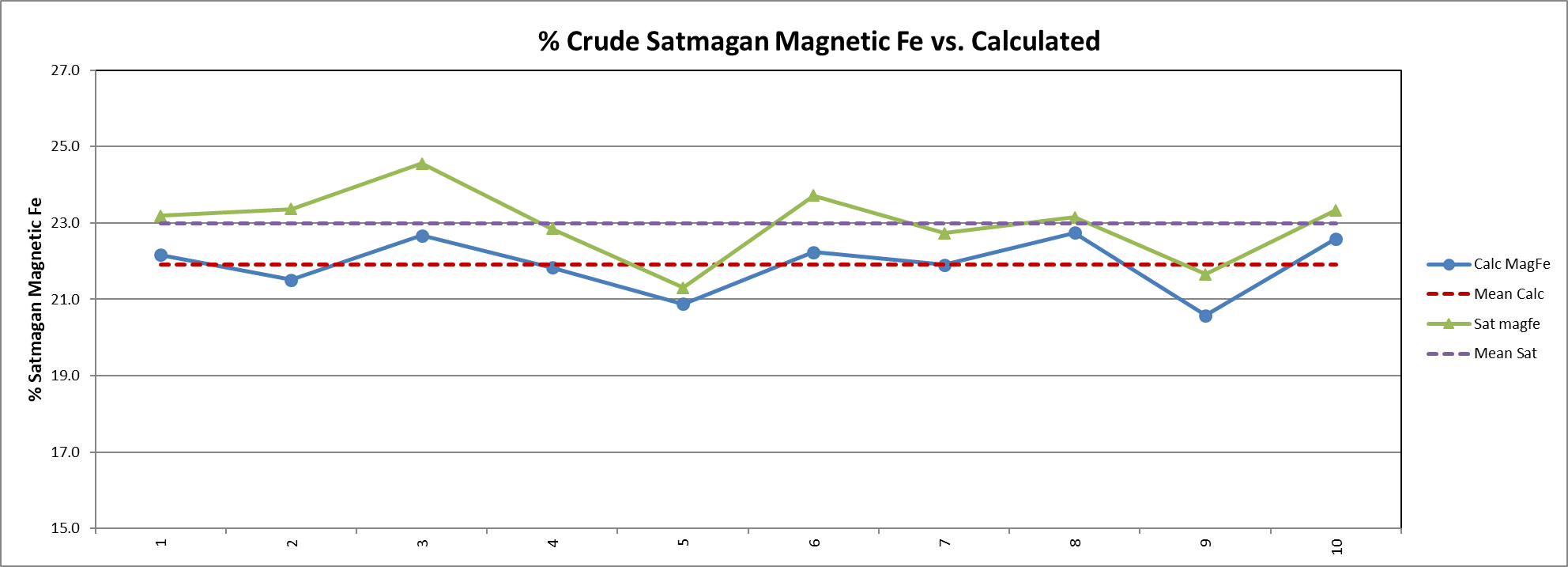

Figure 8-5: Satmagan Magnetic Iron Preparation Duplicates | 71 |

Figure 8-6: Satmagan Magnetic Iron vs. Calculated Magnetic Iron (2021 samples only) | 73 |

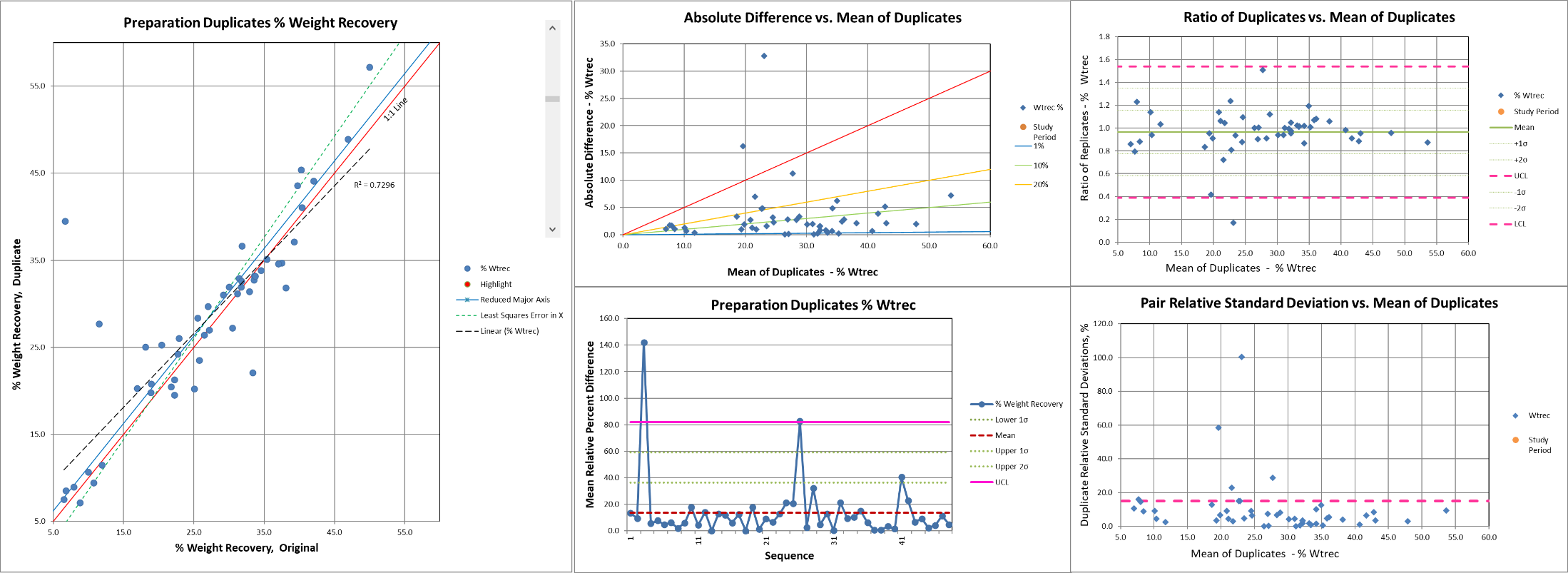

Figure 8-7: Weight Recovery Preparation Duplicates | 75 |

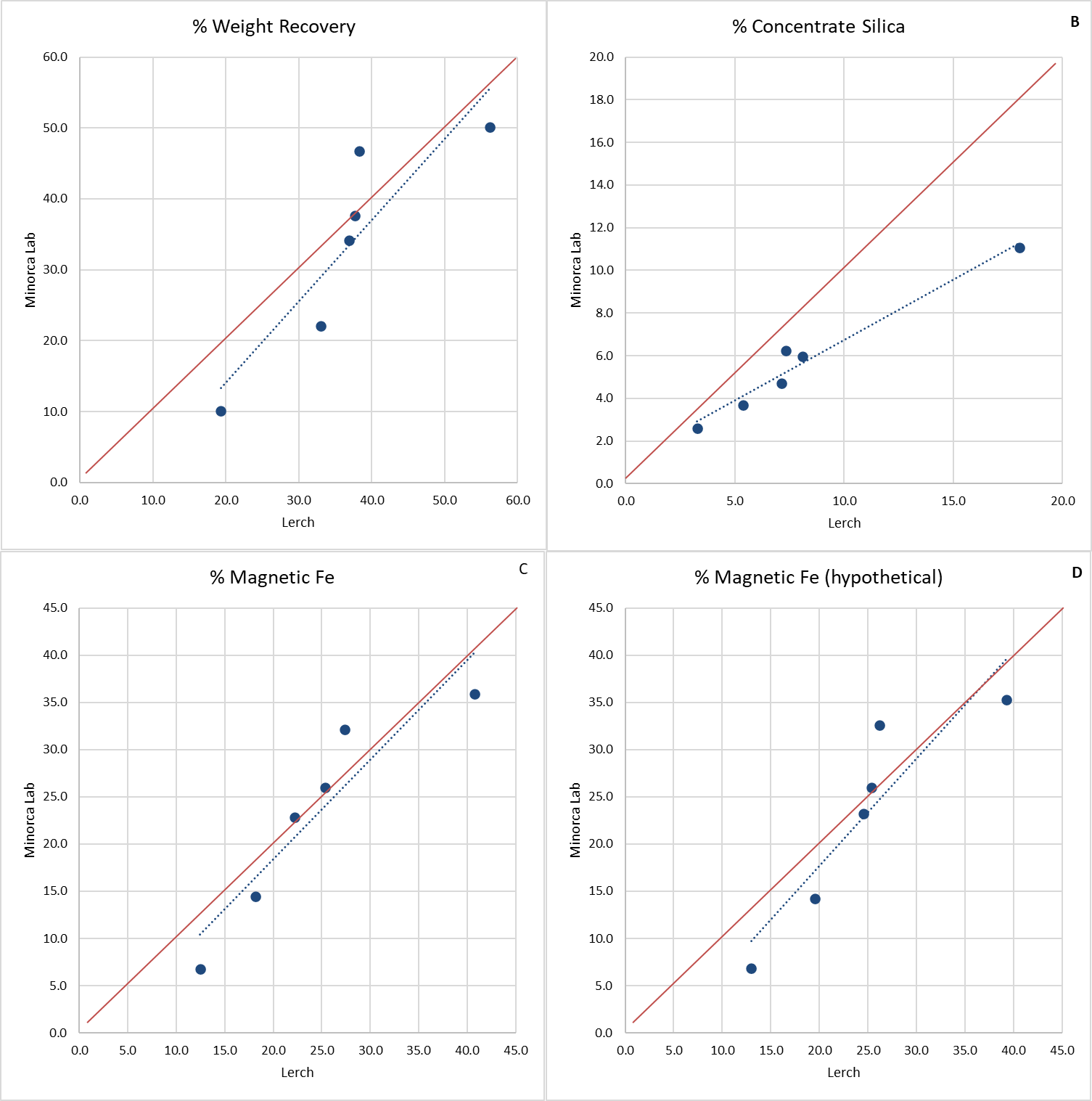

Figure 8-8: Plots of Key Grading Ore Characterization Data for Six Check Samples Processed and Analyzed by Both Lerch and Minorca Laboratories | 77 |

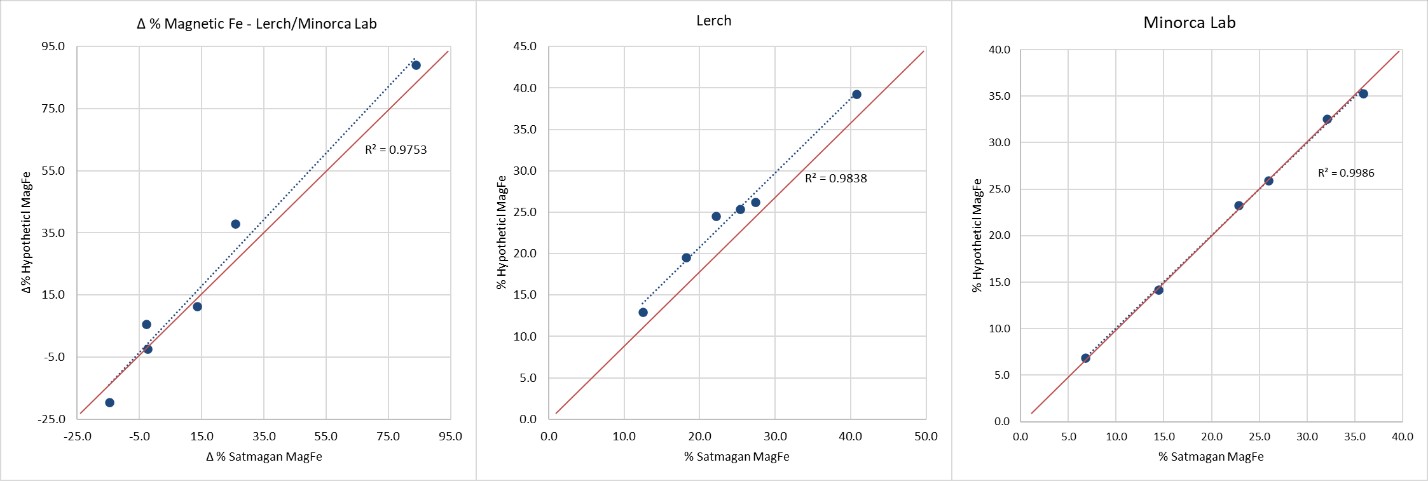

Figure 8-9: Relationship of Satmagan Magnetic Iron and Hypothetical Magnetic Iron (Based On Weight Recovery and Magnetite Stoichiometry) for Minorca and Check Laboratory Samples | 78 |

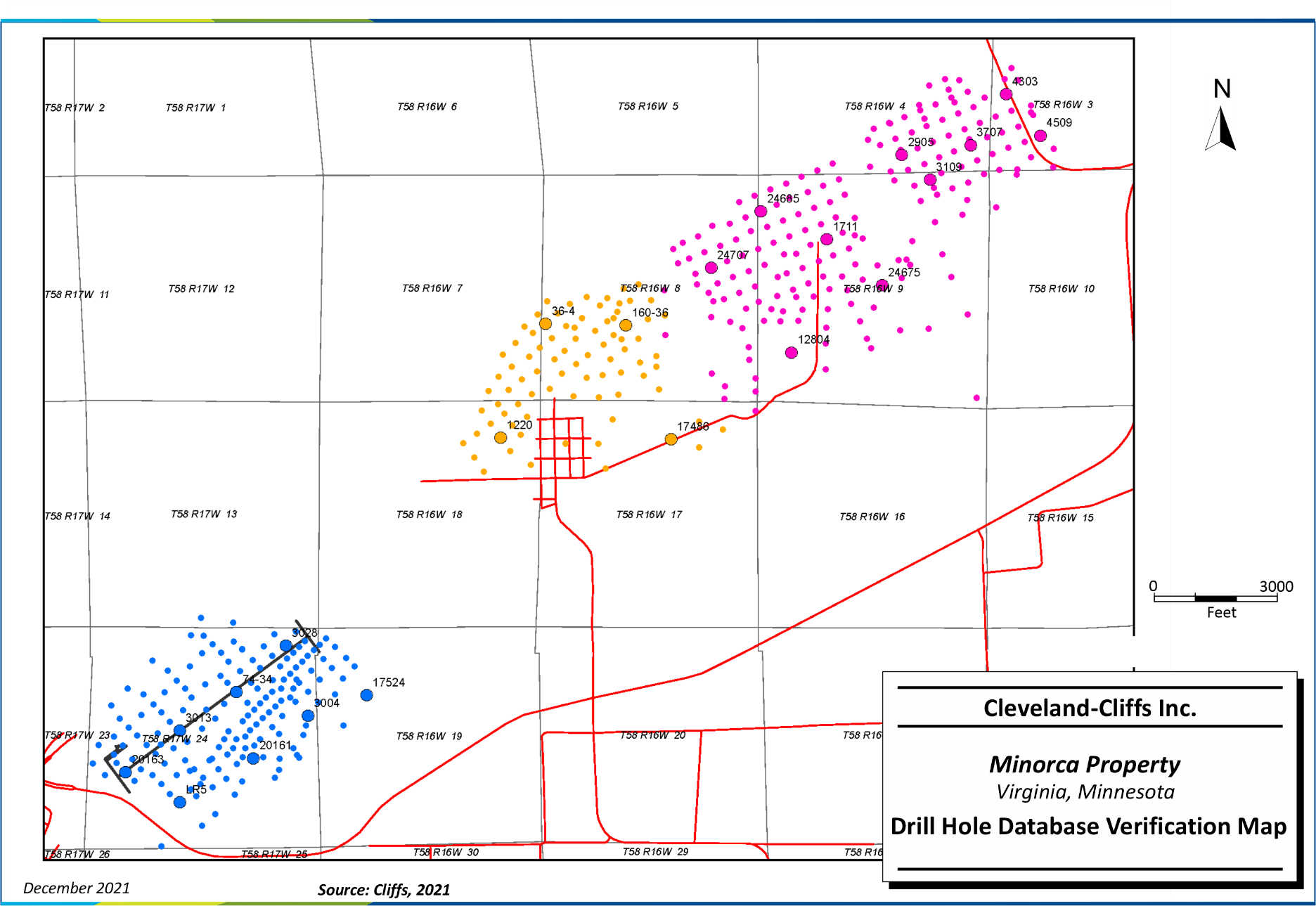

Figure 9-1: Drill Hole Database Verification Map | 83 |

| |

| |

| |

| |

| |

| |

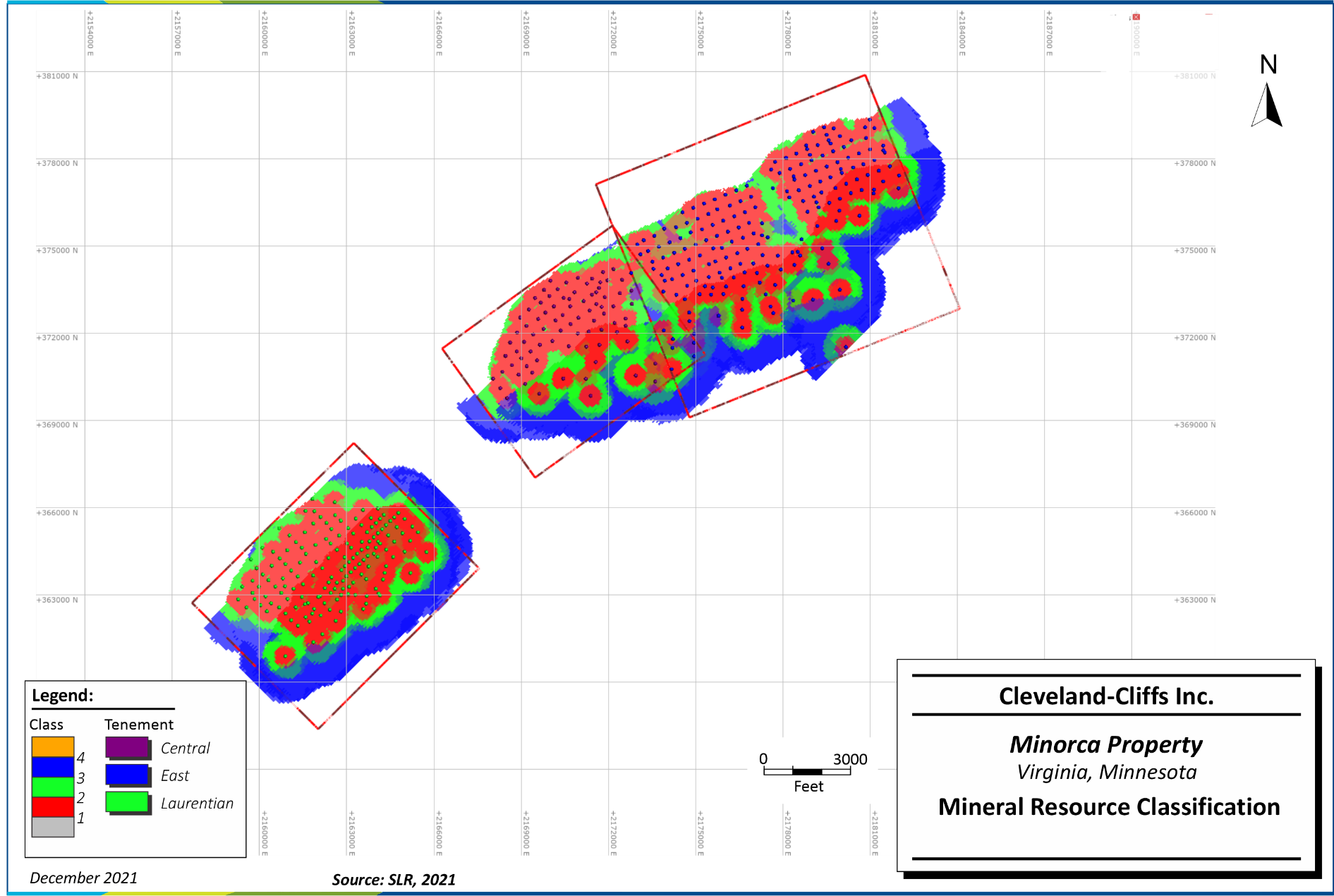

Figure 11-3: Mineral Resource Classification | 108 |

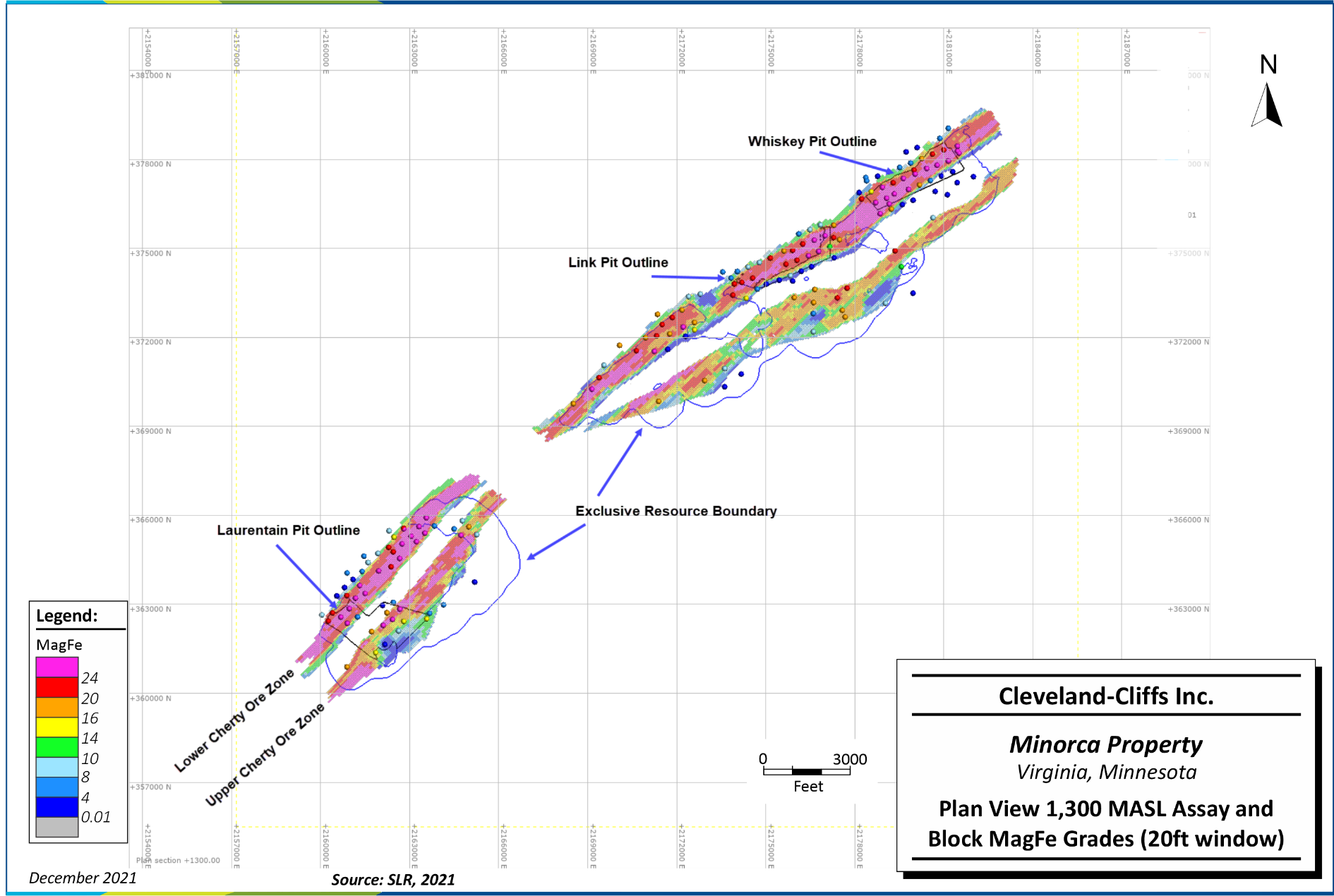

Figure 11-4: Plan View 1,300 MASL Assay and Block MagFe Grades (20 ft Window) | 110 |

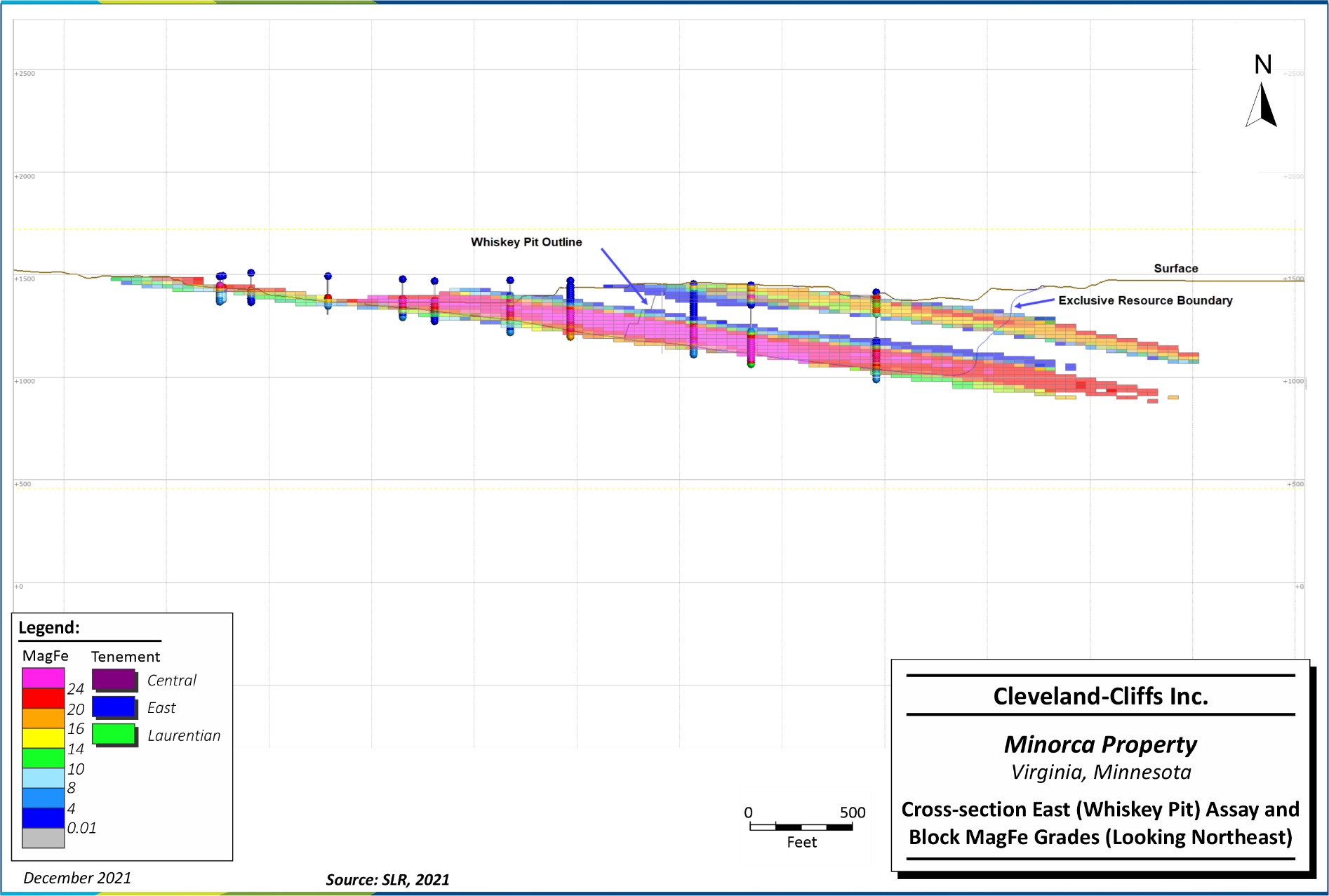

Figure 11-5: Cross-section East (Whiskey Pit) Assay and Block MagFe Grades (Looking Northeast) | 111 |

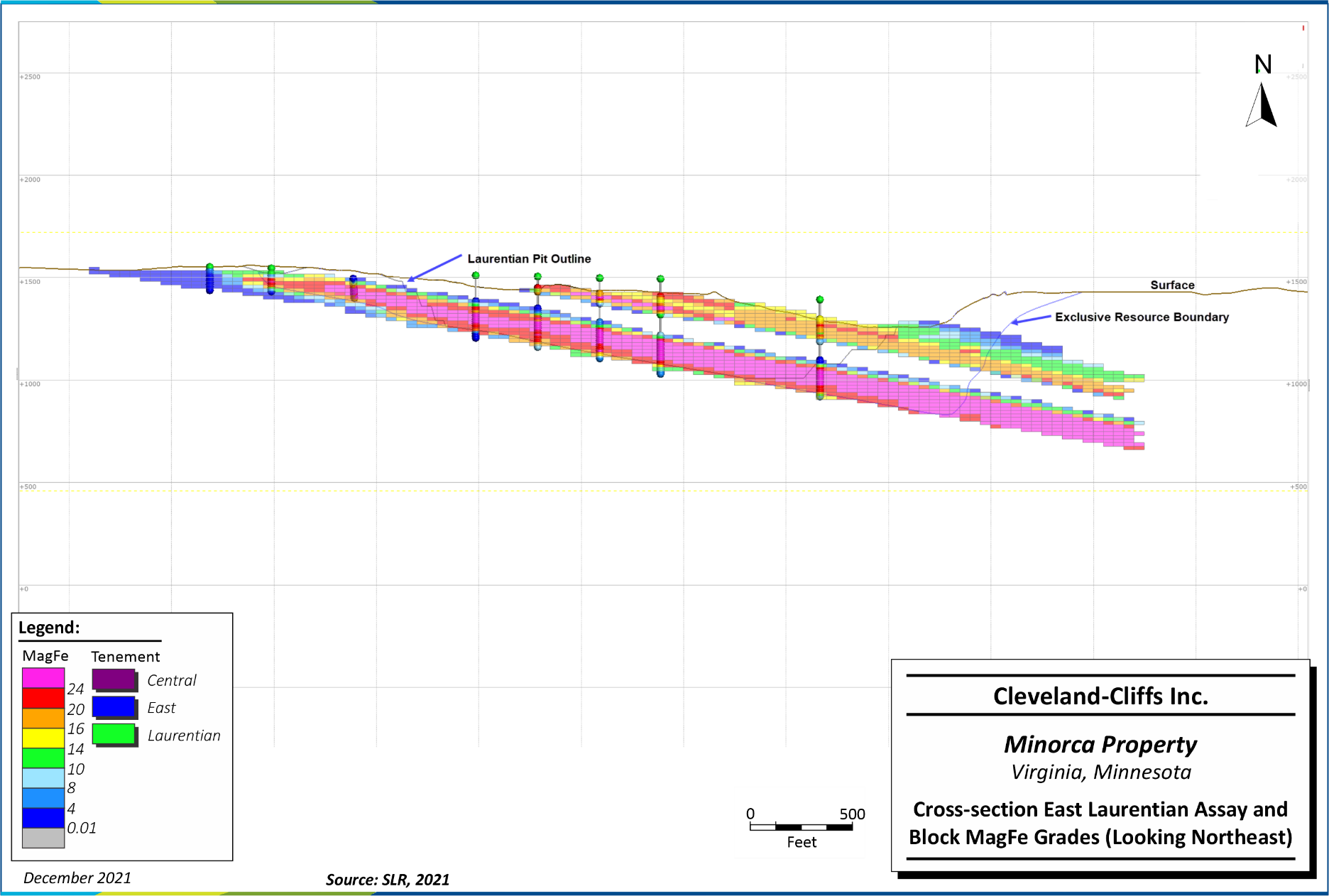

Figure 11-6: Cross-section Laurentian Assay and Block MagFe Grades (Looking Northeast) | 112 |

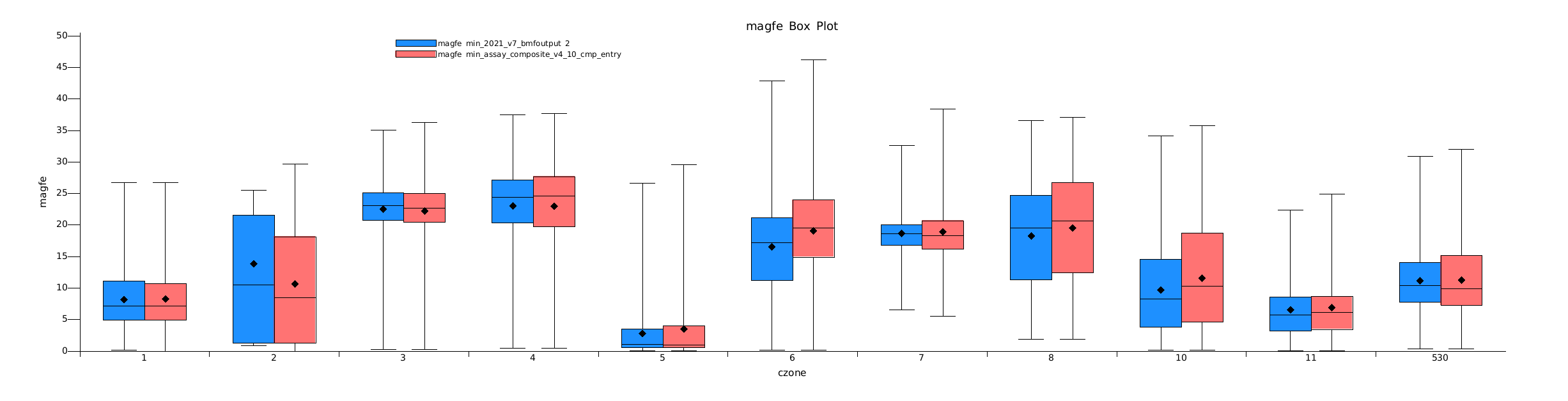

Figure 11-7: Whisker Plots for MagFe Composites and Blocks in All Sub Members in Minorca | 114 |

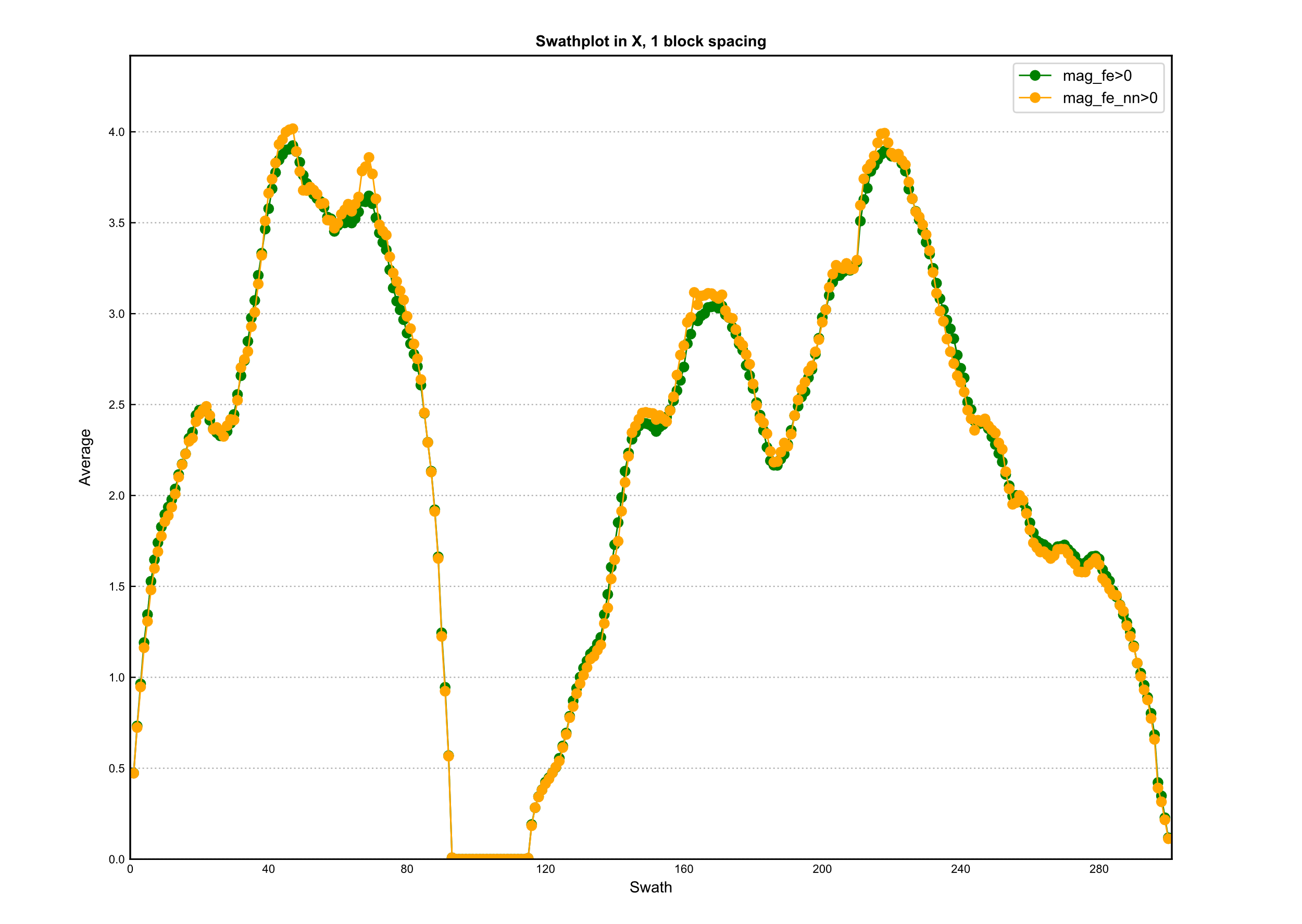

Figure 11-8: East-West (X) Swath Plot for MagFe ID2 versus NN | 115 |

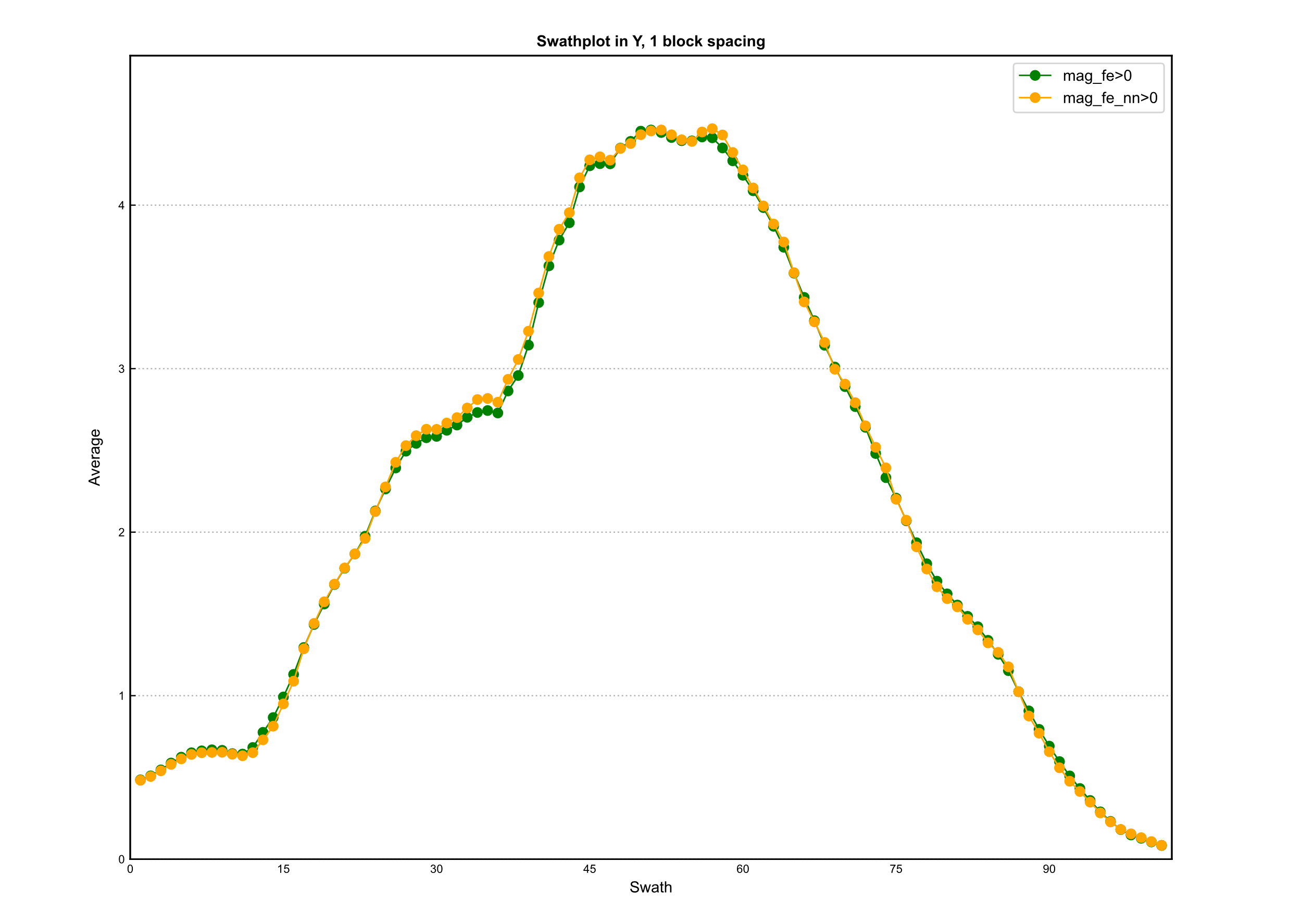

Figure 11-9: North-South (Y) Swath Plot for MagFe ID2 versus NN | 116 |

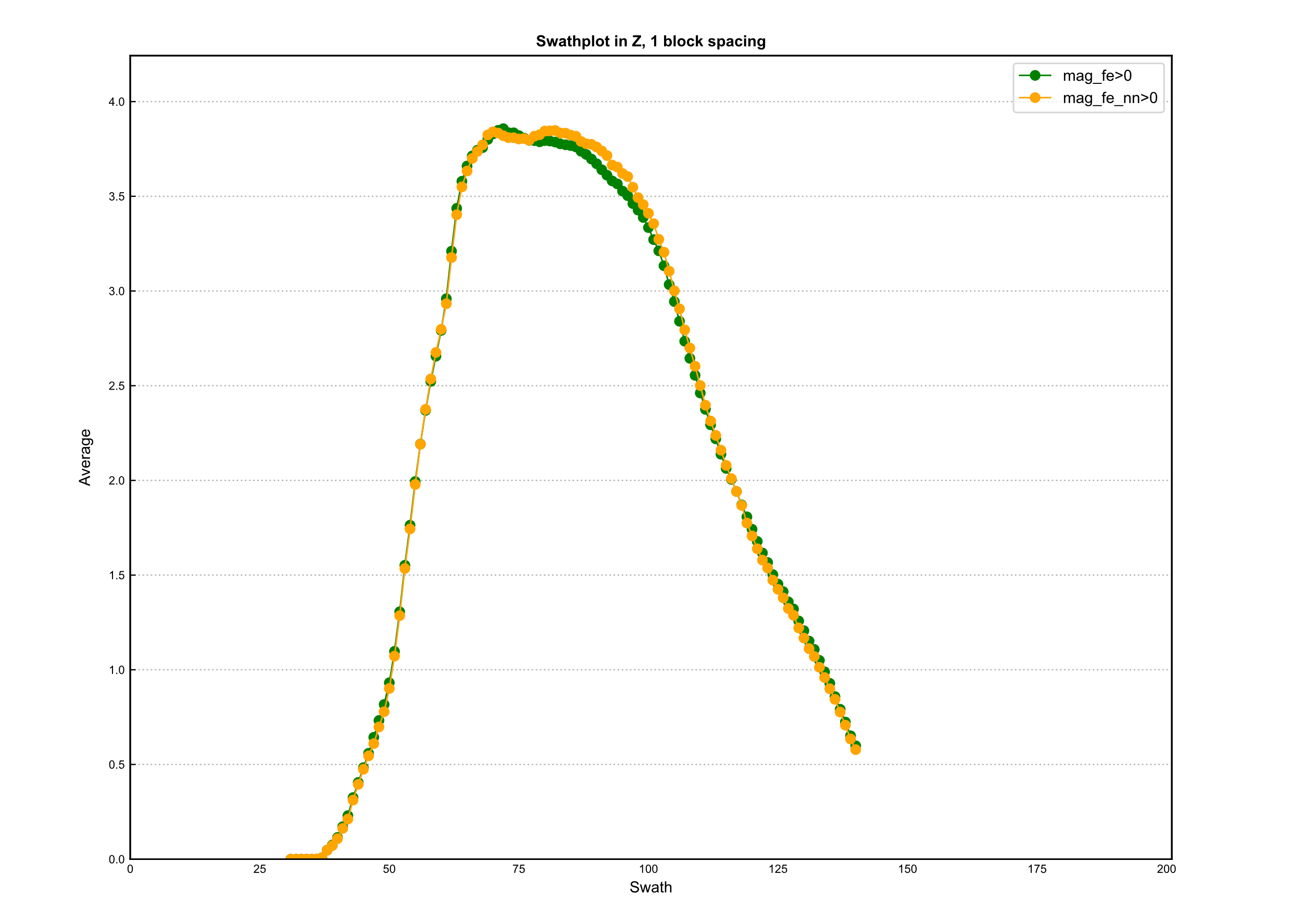

Figure 11-10: Vertical (Z) Swath Plot for MagFe ID2 versus NN | 117 |

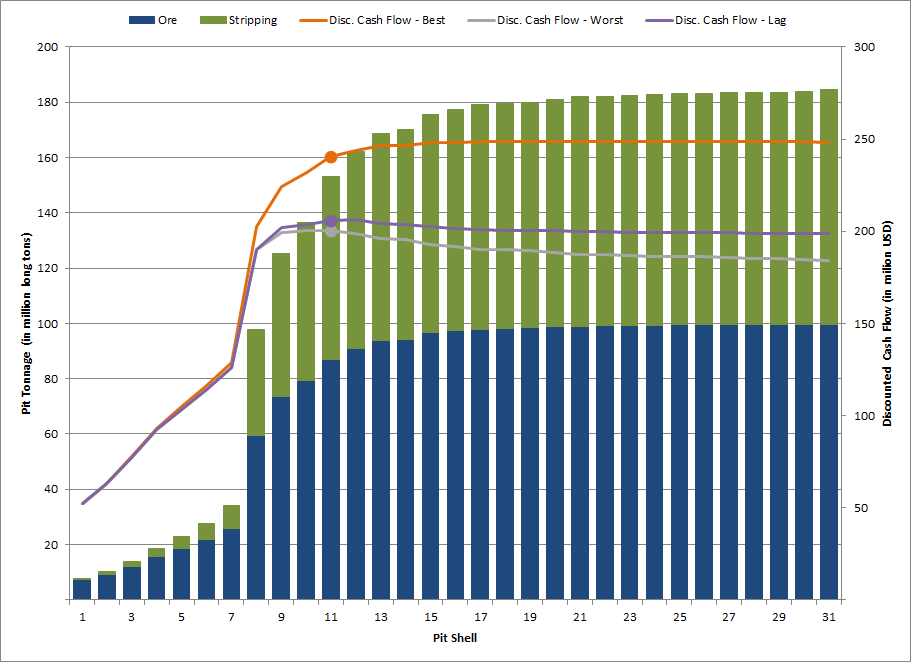

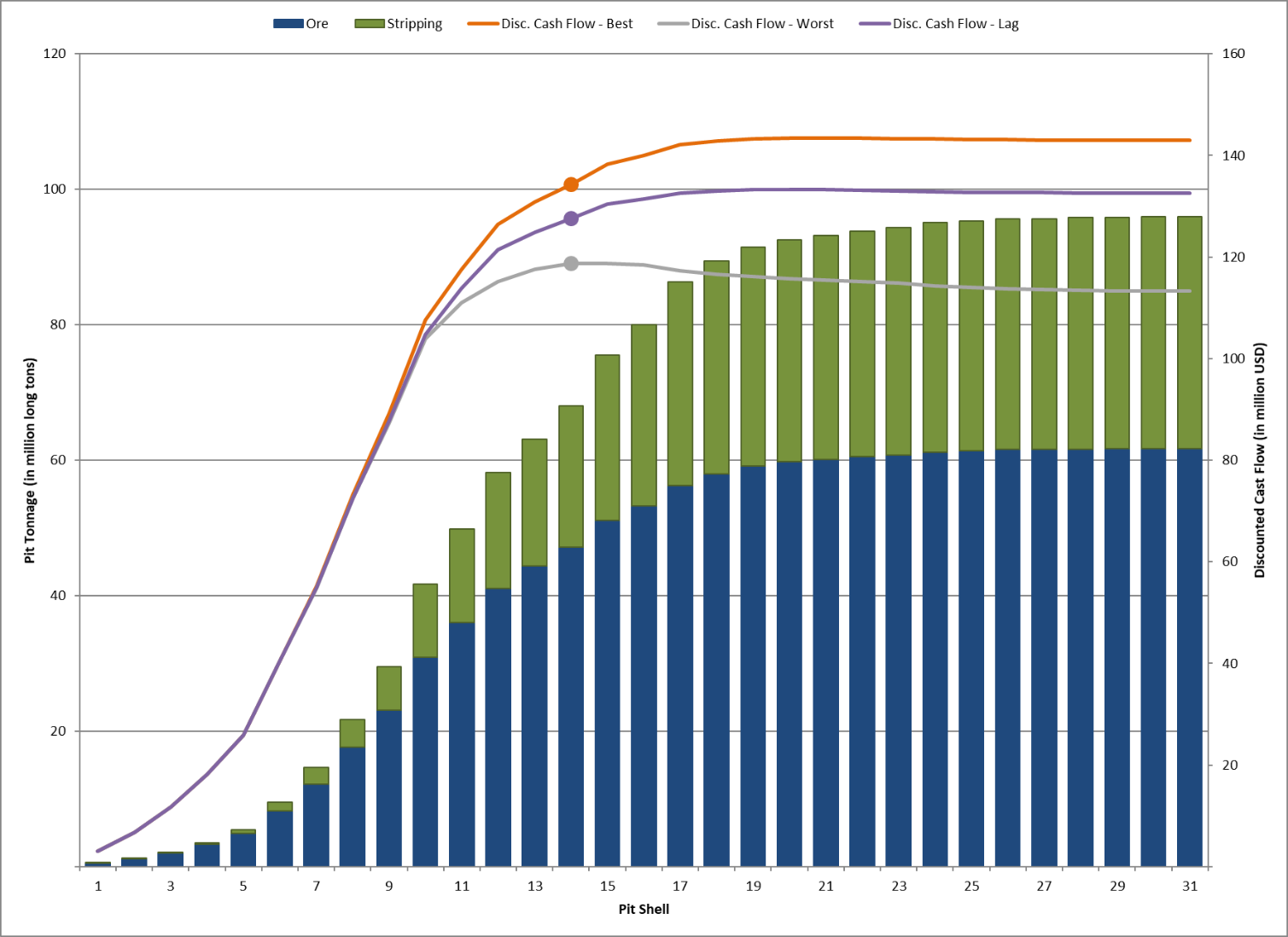

| |

| |

| |

| |

| |

| |

| |

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 vii

| | | | | |

| |

Figure 13-5: Minorca LOM Stockpile Designs | 141 |

| |

| |

| |

Figure 15-3: CN Dock Facilities – Two Harbors, Minnesota | 156 |

Figure 15-4: TSF Location | 157 |

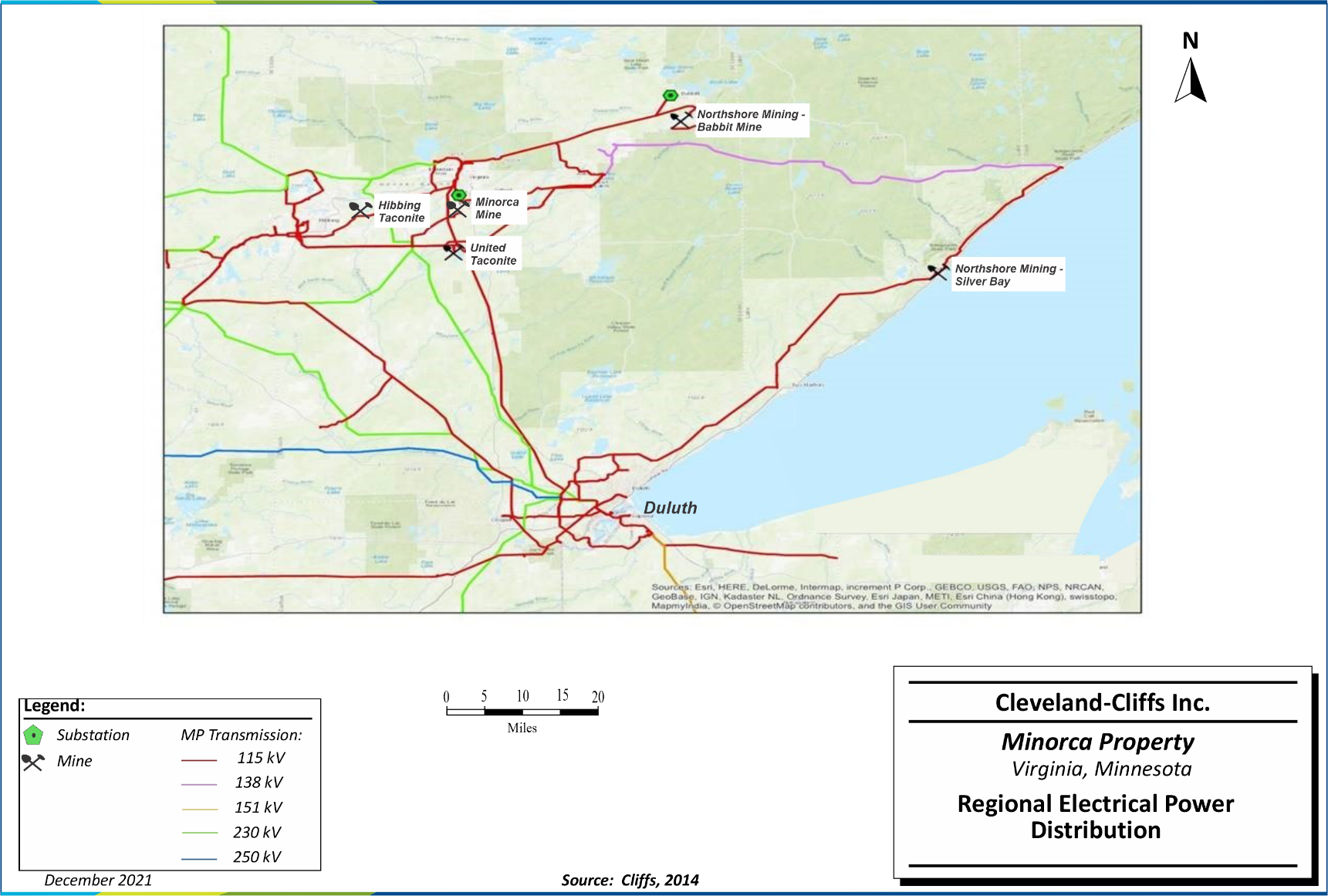

Figure 15-5: Regional Electrical Power Distribution | 161 |

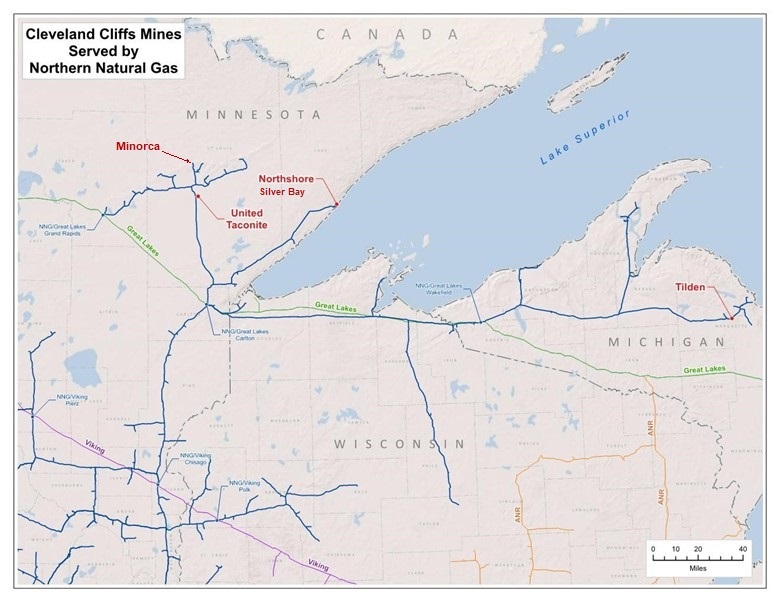

Figure 15-6: Regional Natural Gas Supply | 162 |

Figure 15-7: Aerial View of Minorca Plant Site | 164 |

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 viii

1.0EXECUTIVE SUMMARY

1.1Summary

SLR International Corporation (SLR) was retained by Cleveland-Cliffs Inc. (Cliffs) to prepare an independent Technical Report Summary (TRS) on the Minorca Property (Minorca or the Property), located in St. Louis County, Northeastern Minnesota, USA. The operator of the Property, Cleveland-Cliffs Minorca Mine Inc. (CCMMI), is a wholly owned subsidiary of Cliffs.

The purpose of this TRS is to disclose year-end (YE) 2021 Mineral Resource and Mineral Reserve estimates for Minorca.

Cliffs is listed on the New York Stock Exchange (NYSE) and currently reports Mineral Reserves of pelletized ore in SEC filings. This TRS conforms to the United States Securities and Exchange Commission’s (SEC) Modernized Property Disclosure Requirements for Mining Registrants as described in Subpart 229.1300 of Regulation S-K, Disclosure by Registrants Engaged in Mining Operations (S-K 1300) and Item 601 (b)(96) Technical Report Summary. SLR visited the Property on April 29, 2021.

The Property includes the Laurentian and East Pit mining areas (collectively the Minorca Mine), between Gilbert and Biwabik, Minnesota and a processing facility (the Plant) in Virginia, Minnesota. The Minorca Mine is a complex of large, operating, open-pit iron mines that produces pellets from a magnetite iron ore regionally known as taconite.

The Property commenced operations in 1976 as an asset of Inland Steel Company (Inland Steel). In 1998, ISPAT International (ISPAT) purchased Inland Steel and, in 2004, merged with LNM Holdings and International Steel Group to form Mittal Steel, which in 2007 merged with Arcelor to form ArcelorMittal. The Property has been a wholly owned subsidiary of Cliffs since 2020, when Cliffs purchased the US assets of ArcelorMittal, ArcelorMittal USA (AMUSA).

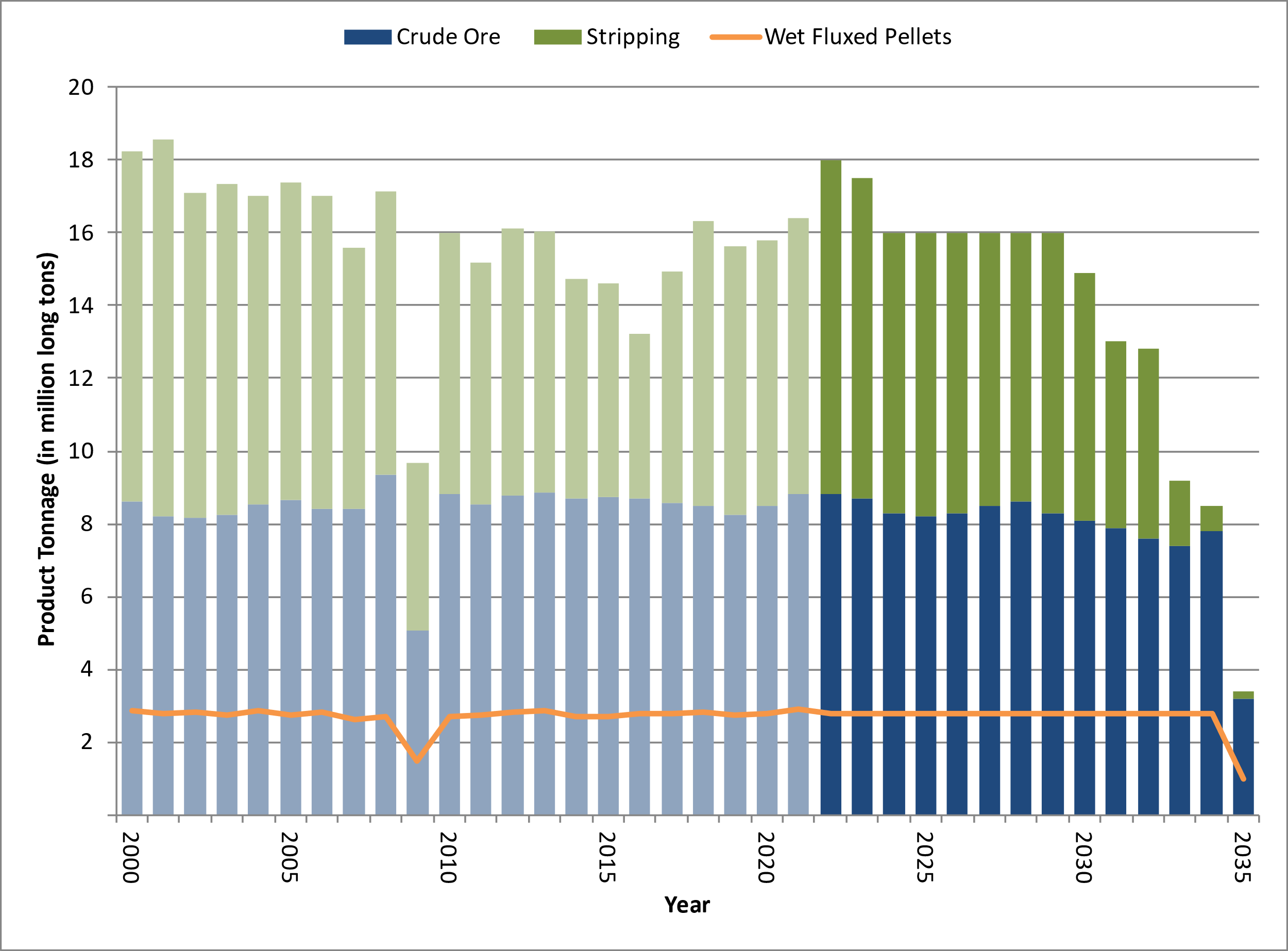

The open-pit operation at Minorca has a mining rate of approximately 8.6 million long tons (MLT) of ore per year and produces 2.8 MLT of wet flux iron ore pellets, which are shipped by freighter via the Great Lakes to Cliffs’ steel mill facilities in the Midwestern USA.

1.1.1Conclusions

Minorca has been a successful producer of iron pellets for over 44 years. The update to the Mineral Resource and Mineral Reserve does not materially change any of the assumptions from previous operations. An economic analysis was performed using the estimates presented in this TRS and confirms that the outcome is a positive cash flow that supports the statement of Mineral Reserves for a 14 year mine life.

SLR offers the following conclusions by area.

1.1.1.1Geology and Mineral Resources

•Above a crude magnetic iron (MagFe) cut-off grade of 16%, Minorca Measured and Indicated Mineral Resources exclusive of Mineral Reserves are estimated to total 801.5 MLT at an average grade of 22.9% MagFe.

•The East, Central, and Laurentian deposits are examples of Lake Superior-type banded iron formation (BIF) deposits. Both the site and corporate technical teams have a strong

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 1

understanding of the Minorca geology, as well as the processing characteristics of the mineralization.

•Exploration sampling, preparation, analyses, and security processes for both physical samples and digital data are appropriate for the style of mineralization and are sufficient to support the estimation of Mineral Resources.

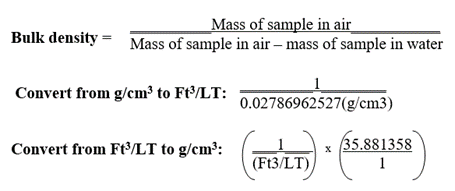

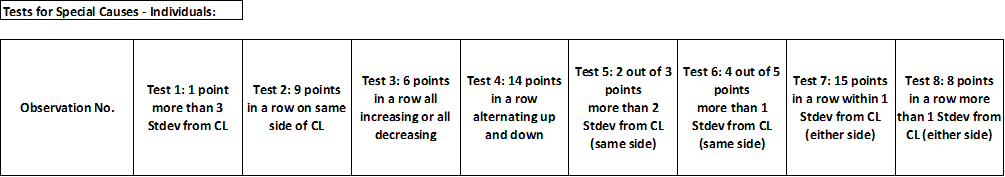

•Cliffs is developing a program of quality assurance and quality control (QA/QC) that includes standards and duplicates and control-chart analysis. A comprehensive QA/QC program did not exist for the previous 44 years of mine operation. QA/QC results for the 2021 verification study are appropriate for the style of mineralization and are sufficient to generate a drill hole assay database that is adequate for Mineral Resource estimation in compliance with international reporting standards. Based on these results, in conjunction with good agreement between planned and actual product produced over more than 40 years, it is SLR’s opinion that procedures meet S-K 1300’s minimum requirements.

•The key economic variables (KEV) in the block models for Minorca compare well with the source data. Future estimations should also review the cut-off grade used in reporting.

•The methodology used to prepare the block model is appropriate and consistent with industry standards.

•Validations compiled by the Qualified Person (QP) indicate that the block model is reflecting the underlying support data appropriately.

•The classification at Minorca is generally acceptable. In SLR’s opinion, however, the extension of classified material beyond drilling limits is slightly aggressive, and some post-processing to remove isolated blocks of different classification is warranted. Classified blocks that extend beyond the drilling limits are generally outside the Resource Pit Shell.

•The block model represents an acceptable degree of smoothing at the block scale for prediction of quality variables at Minorca. Visually, blocks and composites in cross-section and plan view compare well.

•2021 actual versus model-predicted values of crude ore were accurate to within 10%, with the model values slightly lower than actual total ore processed.

1.1.1.2Mining and Mineral Reserves

•Minorca has been in production since 1976, and specifically under 100% Cliffs operating management since 2020. Cliffs conducts its own Mineral Reserve estimations.

•Total Proven and Probable Mineral Reserves are estimated at 109.7 MLT of crude ore at an average grade of 23.8% MagFe.

•Mineral Reserve estimation practices follow industry standards.

•The Minorca Mineral Reserve estimate indicates a sustainable project over a 14 year life of mine (LOM).

•The geotechnical design parameters used for pit design are reasonable and supported by previous operations.

•The LOM production schedule is reasonable and incorporates large mining areas and open benches.

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 2

•An appropriate mining equipment fleet, maintenance facilities, and manpower are in place, with additions and replacements estimated, to meet the LOM production schedule requirements.

•Sufficient storage capacity for waste stockpiles and tailings has been identified to support the production of the Mineral Reserve.

1.1.1.3Mineral Processing

•Minorca’s product has been wholly consumed by Indiana Harbor #7 blast furnace (IH7) since production began in 1977. In 1987, Minorca began creating flux pellets as opposed to standard pellets. In 1992, Minorca constructed a flotation plant for silica reduction to treat the higher silica, Laurentian Pit ores.

•Minorca performs diamond drilling to characterize the Mineral Resource associated with the mine plan. Blast hole samples are analyzed to validate ore grades and develop blending plans. Minorca also conducts plant sampling for process control and product quality reporting for compliance with Standard Product Parameters (SPPs) established by IH7.

•Ore is blended from the Laurentian and East pits based on MagFe content and silica grade as well as scheduled material movement.

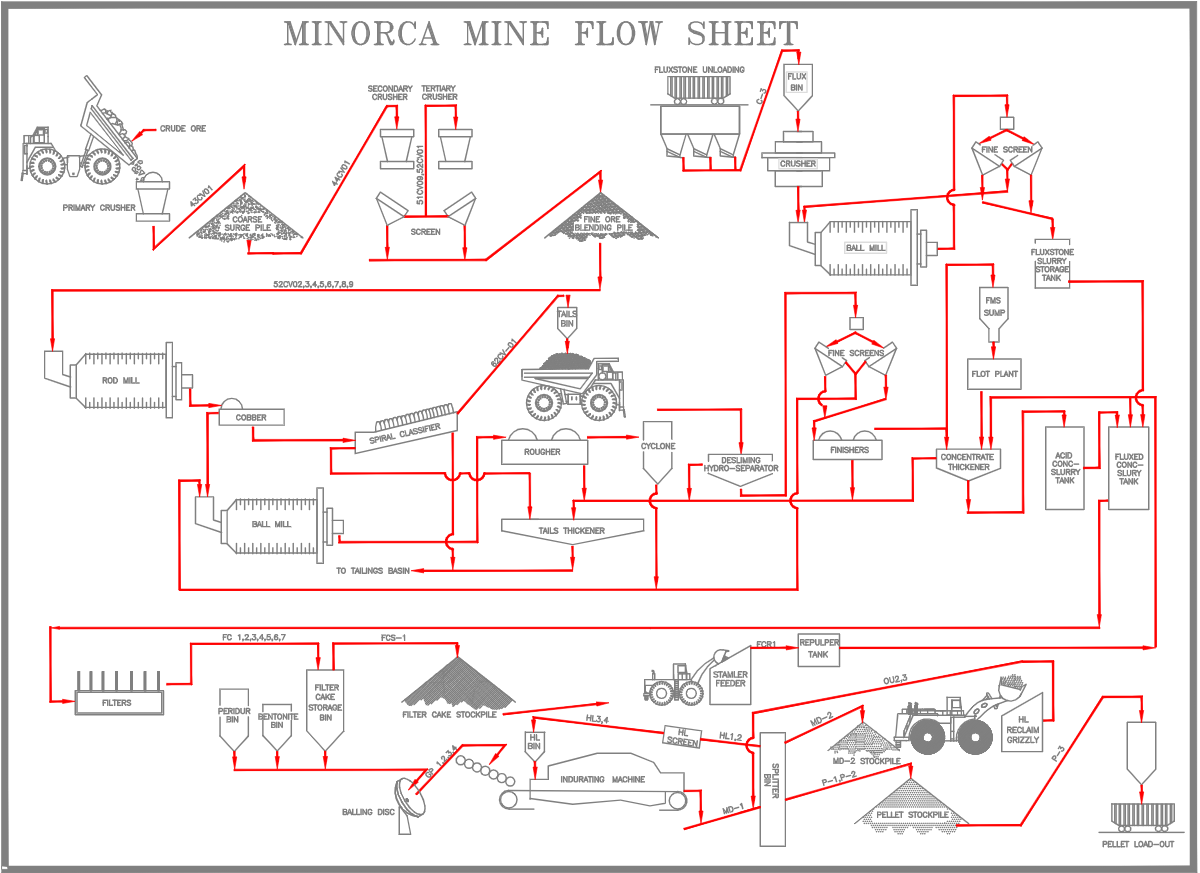

•Crushing, concentrating, and pelletizing processes are conventional. Mined ore is processed in primary, secondary, and tertiary crushers to produce a final product with 100% passing (P100) 5/8 in. that is delivered to the concentrator at a design rate of 1,396 long tons per hour (LT/h).

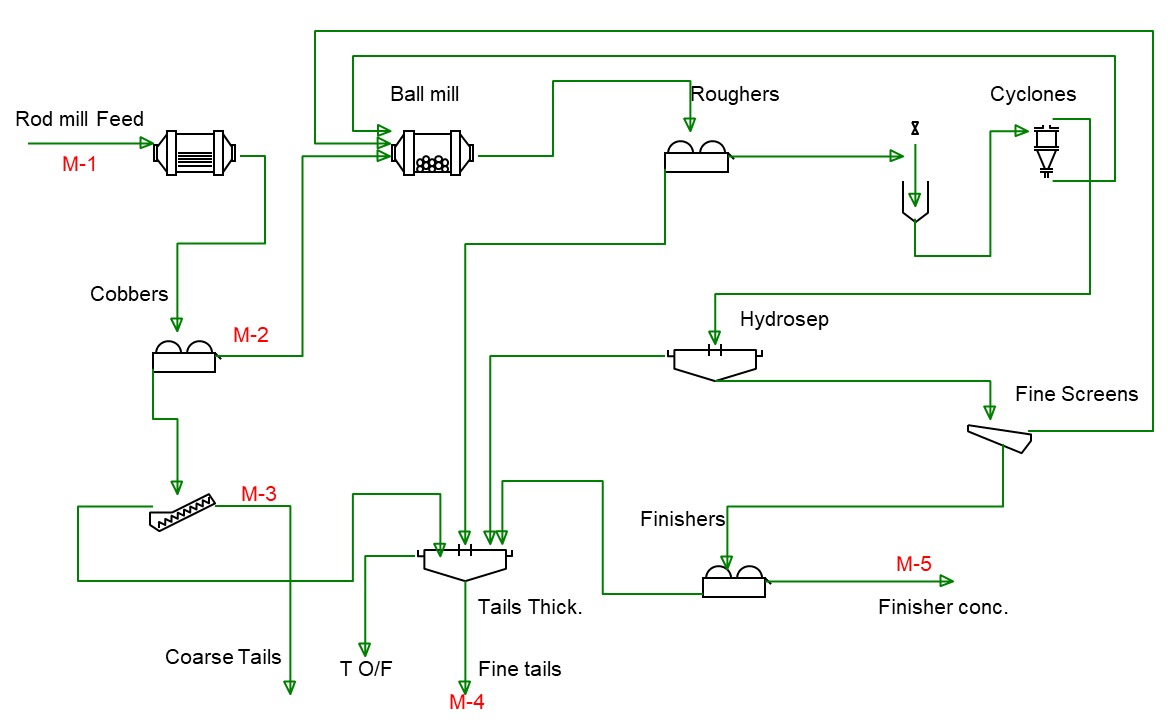

•The concentrator comprises three lines that include rod milling, primary magnetic separation, ball milling, and secondary magnetic separation closed by cyclones, hydroseparation, and finisher magnetic separation to produce a magnetite concentrate.

•Bentonite and dolomite flux are added to the concentrate, which is agglomerated into balls using balling discs and fired in a straight grate indurating furnace to produce a final, hardened, fluxed pellet product.

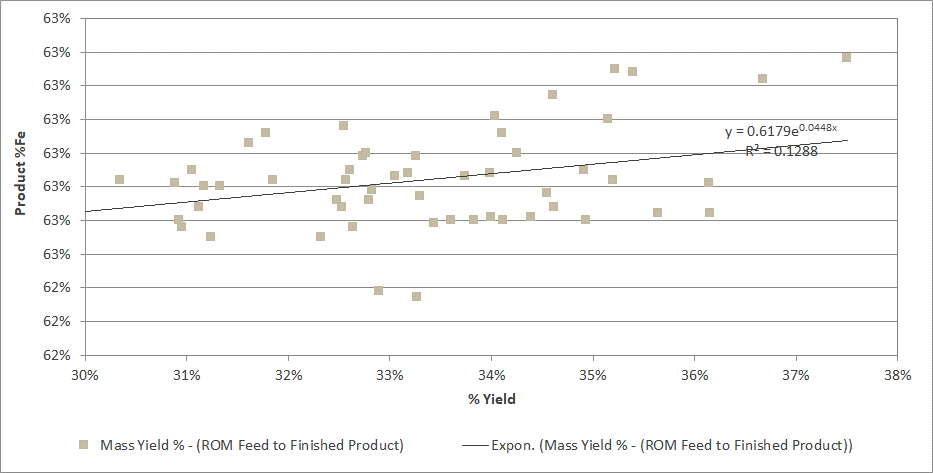

•From 2015 to 2020, the Minorca concentrator processed an average of 8.78 MLT per year (MLT/y) of ore with an average MagFe grade of 22.7%. The overall mass recovery to concentrate averaged 32.5% with an overall MagFe recovery of 95.4%. Final product for the period averaged 2.79 MLT/y of flux pellets and 42,200 LT/y of lump product with grades of 62.6% Fe and 4.2% SiO2.

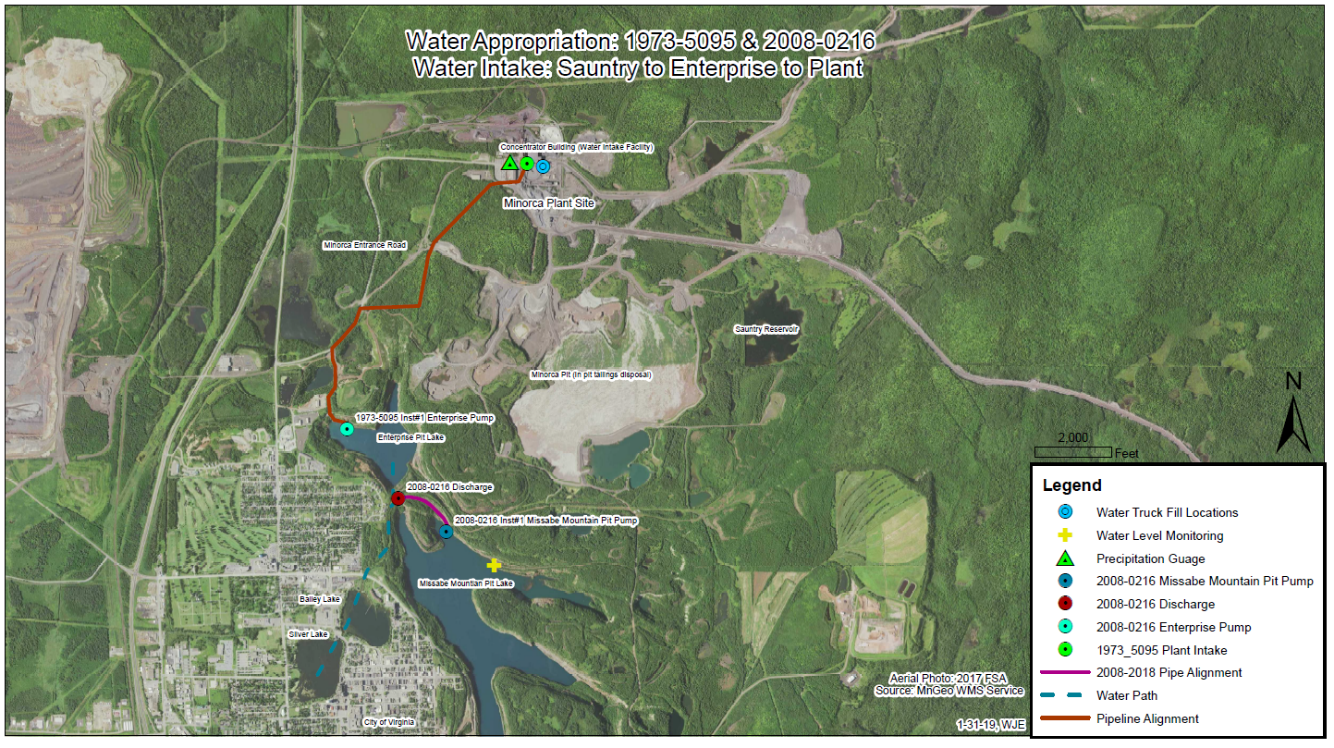

•The main process water supply for the concentrator is recycled from the tailings thickener. Other sources include the Upland and Minorca tailings basins, the Missabe Mountain Pit, the Sauntry/Enterprise Pit, and the Plant Site settling basin.

1.1.1.4Infrastructure

•The Property is located in a historically important, iron-producing region of Northeastern Minnesota. All the infrastructure necessary to mine and process significant commercial quantities of iron ore is in place.

•Cliffs has been operating the Upland Tailings Basin as a disposal site for fine tailings since the mid-1970s and the In-Pit Tailings Basin since 2001, both of which are currently operating under the permit requirements of the Minnesota Department of Natural Resources Dam Safety Unit

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 3

1.1.1.5Environment

•Minorca maintains the requisite state and federal permits and is in compliance with all permits. Environmental liabilities and permitting are further discussed in Section 17.0 of this TRS.

1.1.2Recommendations

1.1.2.1Geology and Mineral Resources

1.Continue to develop and expand the QA/QC program to ensure that the program includes clearly defined limits when action or follow-up is required, and that results are reviewed and documented in a report, including conclusions and recommendations, regularly and in a timely manner.

a.Complete ISO certification for the Minorca laboratory.

b.Develop a formal QA/QC procedure that includes preparation of a QA/QC campaign report following every annual diamond drilling program.

c.Continue to submit a small number of “preparation duplicate” samples to a secondary accredited laboratory to document capability(ies), cost, and time efficiency of alternate provider(s) and confirm that results are comparable to those of Minorca’s internal laboratory.

d.Add sample completion date to all diamond drill hole certificates of analysis returned to the mine geologist.

2.Apply a minimum of two holes during the first pass estimation for Minorca in future updates.

3.In future updates, use local drill hole spacing instead of a distance-to-drill hole criterion for block classification.

4.Prepare model reconciliation over quarterly periods and document methodology, results, and conclusions and recommendations.

5.Continue to update Minorca Mineral Resource estimates with new drilling.

1.1.2.2Mining and Mineral Reserves

1.Complete additional work at Minorca to support conversion of on-strike Mineral Resources to Mineral Reserves and update mine planning accordingly.

2.Review potential comingling of waste rock stockpiles between the Minorca pits for opportunities to reduce the stockpile footprint created external to the open pits and reduce waste haulage profiles.

1.1.2.3Mineral Processing

1.Follow the established procedures for sampling and testing to support ore blending and ensure operational consistency and preventive maintenance.

1.1.2.4Infrastructure

1.Prioritize the completion of an Operations, Maintenance and Surveillance (OMS) Manual for the tailings storage facility (TSF) with the Engineer of Record (EOR) in accordance with Mining

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 4

Association of Canada (MAC) guidelines and other industry-recognized standard guidance for tailings facilities.

2.Document, prioritize, track, and close out in a timely manner the remediation, or resolution, of items of concern noted in TSF audits or inspection reports.

1.2Economic Analysis

1.2.1Economic Criteria

An un-escalated technical-economic model was prepared on an after-tax, discounted cash flow (DCF) basis, the results of which are presented in this subsection. Key criteria used in the analysis are discussed in detail throughout this TRS. General assumptions used are summarized in Table 1-1 with all physicals reported per wet long ton (WLT) pellet.

Table 1-1: Technical-Economic Assumptions

Cleveland-Cliffs Inc. – Minorca Property

| | | | | |

| Description | Value |

| Start Date | December 31, 2021 |

| Mine Life | 14 years |

| Three-Year Trailing Average Revenue | $98/WLT pellet |

| Operating Costs | $85.53/WLT pellet |

| Sustaining Capital (after five years) | $4/WLT pellet |

| Discount Rate | 10% |

| Discounting Basis | End of Period |

| Inflation | 0.0% |

| Federal Income Tax | 20% |

| State Income Tax | None – Sales made out of state |

Table 1-2 presents a summary of the estimated mine production over the 14 year mine life.

Table 1-2: LOM Production Summary

Cleveland-Cliffs Inc. – Minorca Property

| | | | | | | | |

| Description | Units | Value |

| Run of Mine (ROM) Crude Ore | MLT | 109.7 |

| Total Material | MLT | 193.2 |

| Grade | % MagFe | 23.8 |

| Annual Mining Rate | MLT/y | 16 |

Table 1-3 presents a summary of the estimated plant production over the 14 year mine life.

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 5

Table 1-3: LOM Plant Production Summary

Cleveland-Cliffs Inc. – Minorca Property

| | | | | | | | |

| Description | Units | Value |

| ROM Material Milled | MLT | 109.7 |

| Annual Processing Rate | MLT/y | 8.5 |

| Process Recovery | % | 34.2 |

| Total Pellet | MLT | 37.4 |

| Annual Pellet Production | MLT/y | 2.8 |

1.2.2Cash Flow Analysis

The indicative economic analysis results, presented in Table 1-4, indicate an after-tax Net Present Value (NPV), using a 10% discount rate, of $70 million at an average blended wet pellet price of $98/WLT. SLR notes that after-tax Internal Rate of Return (IRR) is not applicable, as the processing facility has been in operation for a number of years. Capital identified in the economics is for sustaining operations and plant rebuilds as necessary.

The economic analysis was performed using the estimates presented in this TRS and confirms that the outcome is a positive cash flow that supports the statement of Mineral Reserves.

Table 1-4: LOM Indicative Economic Results

Cleveland-Cliffs Inc. – Minorca Property

| | | | | | | | |

| Description | $ Millions | $/WLT Pellet |

| Three-Year Trailing Revenue ($/WLT Pellet) | | 98 |

| Pellet Production (MWLT) | 37.4 | |

| Gross Revenue | 3,659 | |

| Mining | 631 | 16.89 |

| Processing | 1,701 | 45.57 |

| Site Administration | 82 | 2.20 |

| Logistics/Dock | 403 | 10.78 |

| General / Other Costs | 377 | 10.10 |

| Total Operating Costs | 3,193 | 85.53 |

| Operating Income (excl. D&A) | 465 | 12.47 |

| Federal Income Tax | (93) | (249) |

| Depreciation Tax Savings | 49 | 1.31 |

| Accretion Tax Savings | 4 | 0.11 |

| Net Income after Taxes | 425 | 11.39 |

| Capital | 210 | (5.63) |

| Closure Costs | 29 | (0.79) |

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 6

| | | | | | | | |

| Description | $ Millions | $/WLT Pellet |

| Cash Flow | 186 | 4.98 |

| NPV 10% | 70 | |

1.2.3Sensitivity Analysis

The Minorca operation is nominally most sensitive to market prices (revenues) followed by operating cost. For each dollar movement in sales price and operating cost, respectively, the after tax NPV changes by approximately $18 million.

1.3Technical Summary

1.3.1Property Description

The Property is located in St. Louis County, Northeastern Minnesota, USA, on the Mesabi Iron Range, between the towns of Virginia, Gilbert, and Biwabik, Minnesota. The Laurentian Pit is located near the City of Gilbert, Minnesota at latitude 47°30'0"N and longitude 92°26’30"W, East 1 (also termed Lynx) Pit is located at latitude 47°31'30"N and longitude 92°23’30"W, and East 2 (also termed Whiskey) Pit is located just west of the City of Biwabik at latitude 47°32'0"N and longitude 92°22’30"W. The Minorca Plant is located approximately seven miles (mi) to the northeast, near the town of Virginia, Minnesota at latitude 47°33'30"N and longitude 92°31.5'30"W. The Property has the capacity to produce approximately 2.8 MLT of wet flux iron ore pellets annually.

Cliffs controls 16,825 acres of mineral titles and surface rights in the Property through leases and direct ownership through its wholly owned subsidiary CCMMI.

1.3.2Accessibility, Climate, Local Resources, Infrastructure, and Physiography

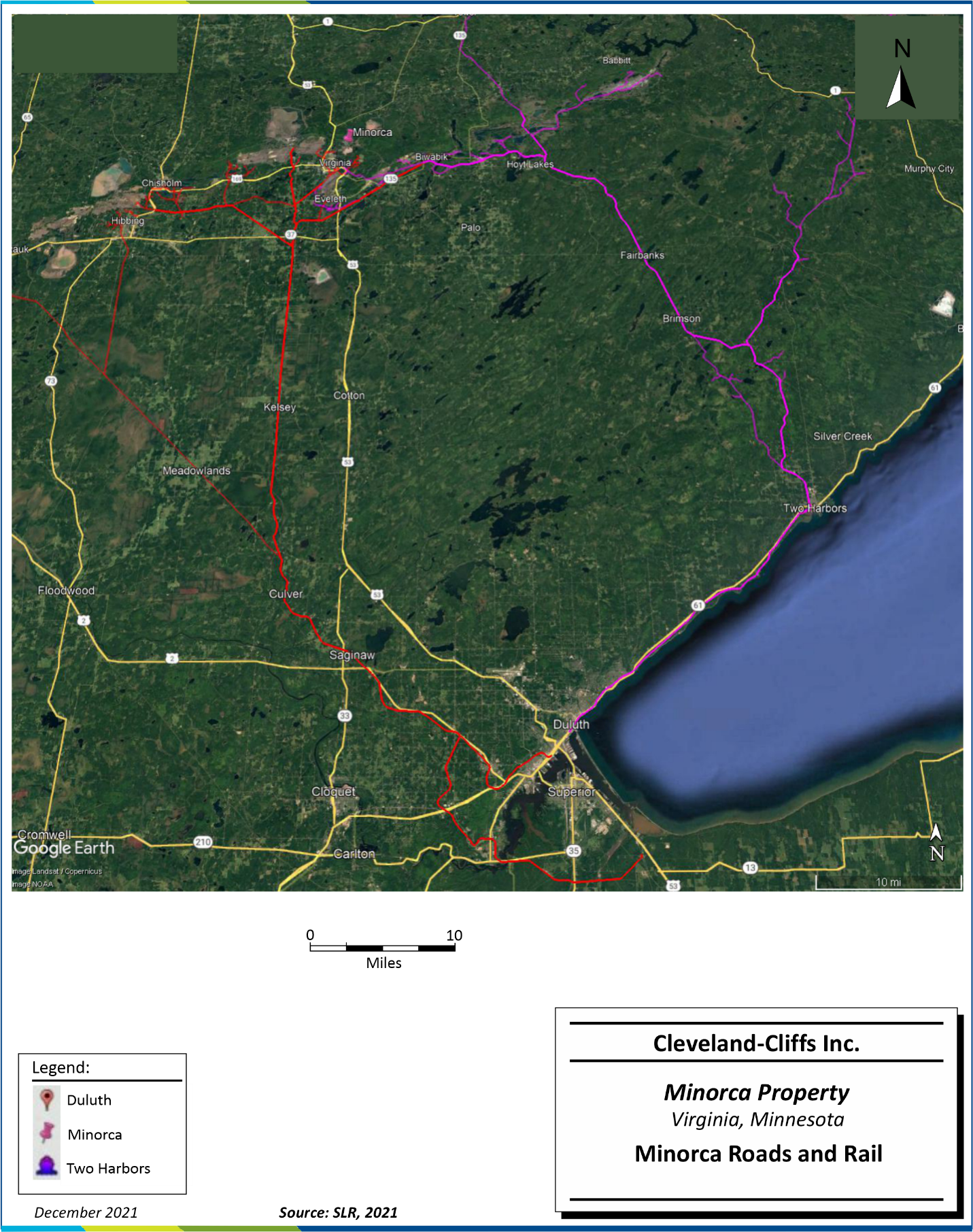

The Property is easily accessed via paved roads from Virginia, approximately one mile to the west, or the towns of Gilbert and Biwabik, approximately one mile to the west and east, respectively. A rail line operated by Canadian National Railway (CN) extends from the Minorca processing facility to the port of Two Harbors, Minnesota, a major port city on Lake Superior, which is 75 mi southeast of the Property. Duluth, Minnesota is also 69 mi southeast of Virginia via US Highway 53 and 27 mi southwest of Two Harbors via MN Highway 61. Duluth also has a regional airport with several flights daily to major hubs in Minneapolis, Minnesota and Chicago, Illinois.

The climate in northern Minnesota ranges from mild in the summer to winter extremes. The annual average temperature is 36.9°F. The annual average high temperature is 48.6°F, whereas the annual average low temperature is 25.1°F. By month, July is on average the hottest month (77°F), with January being the coldest (-4°F).

The Minorca operation employs 362 personnel who live in the surrounding cities of Virginia, Eveleth, Gilbert, and Hibbing. Personnel also commute from Duluth and the Iron Range. St. Louis County has an estimated population of 200,000 people.

The Property is located in a historically important, iron-producing region of Northeastern Minnesota. All the infrastructure necessary to mine and process significant commercial quantities of iron ore is currently in place. Infrastructure items include high voltage electrical supplies, natural gas pipelines that

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 7

connect to the North American distribution system, water sources, paved roads and highways, railroads for transporting ROM crude ore and finished products, port facilities that connect to the Great Lakes, and accommodations for employees. Local and State infrastructure also includes hospitals, schools, airports, equipment suppliers, fuel suppliers, commercial laboratories, and communication systems.

The Property is at an elevation of approximately 1,700 feet above sea level (fasl). The generally gentle topography in the area is punctuated by hummocky hills and long, gentle moraines, remnants of glacial ingress and egress. The landscape ranges from semi-rugged, lake-dotted terrain with thin glacial deposits over bedrock, to hummocky or undulating plains with deep glacial drift, to large, flat, poorly drained peatlands. The Minnesota Department of Natural Resources characterizes the area as being within the Laurentian Mixed Forest (LMF) Province. In Minnesota, the LMF is characterized by broad areas of conifer forest, mixed hardwood and conifer forests, and conifer bogs and swamps.

1.3.3History

Exploration for high-grade, direct-shipping iron ore (DSO) deposits in the Virginia area began in the 1890s. Focused exploration for beneficiation-grade magnetite deposits, regionally known as taconite deposits, however, did not begin until the 1940s.

The Minorca Mine and Plant began production in 1977 as an asset of Inland Steel, with an initial production rate of 2.56 MLT/y of standard iron ore pellets. Flux pellet production commenced in 1987, and since then, through a multitude of operational improvements, the Plant has increased production to 2.85 MLT/y of pellets. A flotation plant was added in 1992 so that the Plant could utilize the higher silica ore coming from the Laurentian Pit.

In 1998 the Property was purchased by ISPAT, which subsequently became part of a 2005 merger between ISPAT, LNM Holdings, and International Steel Group to form Mittal Steel. In 2007, Mittal Steel merged with Arcelor to form ArcelorMittal. The Property was idled for six months in 2009 to conserve cash for the parent company during the economic downturn of the period. This represented the only time in the history of the Property that the operation was idled for economic reasons.

In 2020, Cliffs purchased the US-based assets of ArcelorMittal and now holds a 100% interest in the Property through its wholly owned subsidiary CCMMI.

1.3.4Geological Setting, Mineralization, and Deposit

The Minorca deposits are examples of Superior-type BIF deposits, specifically the Biwabik Iron Formation (Biwabik IF), which is interpreted to have been deposited in a shallow, tidal marine setting and is characterized as having four main members (from bottom to top): Lower Cherty, Lower Slaty, Upper Cherty, and Upper Slaty. Cherty units generally have a sandy granular texture, are thickly bedded, and are composed of silica and iron oxide minerals. Slaty units are fine grained, thinly bedded, and comprised of iron silicates and iron carbonates, with local chert beds, and they are typically uneconomic. The mineral of economic interest at Minorca is magnetite. The nomenclature of the members is not indicative of metamorphic grade; instead, slaty and cherty are colloquial descriptive terms used regionally.

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 8

1.3.5Exploration

Diamond drilling (DD) is the principal method of exploration utilized at Minorca. A combination of historical and current DD core drilled by Cliffs and its predecessors is used in mine planning. Near-mine exploration is conducted on approximately 400 ft centers. In June 2021, Cliffs contracted EDCON-PRJ to fly a high-resolution aeromagnetic survey over its nearby United Taconite operation; the survey extended over the Minorca property and was completed for the purpose of understanding large-scale structural features and BIF oxidation.

1.3.6Mineral Resource Estimates

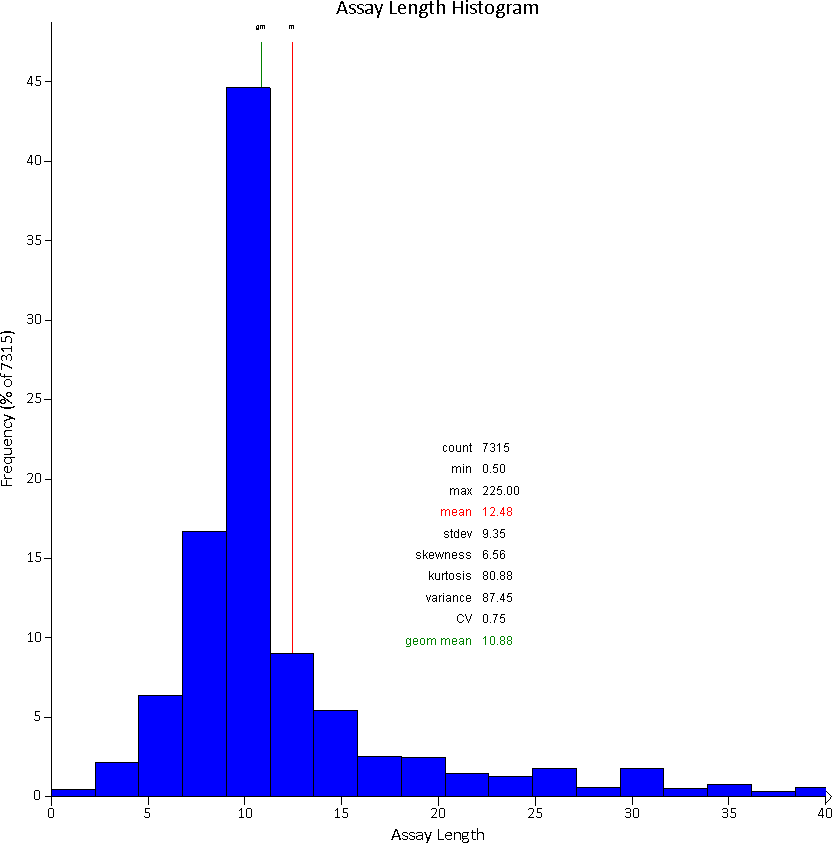

Mineral Resource estimates for the Minorca deposit were prepared by Cliffs and audited and accepted by SLR using available data from 1958 to 2021. Mineral Resource estimates are based on 443 DD drill holes totaling 118,809 ft completed since drilling began in 1958.

The 2021 Minorca Mineral Resource estimate was completed using a conventional block modeling approach. The general workflow included the construction of a geological or stratigraphic model representing the Biwabik IF by SLR in Seequent’s Leapfrog Geo (Leapfrog Geo) from mapping, drill hole logging, and sampling data, which were used to define discrete domains and surfaces representing the upper contact of each unit of non-iron formation and iron formation subunits. The geologic model was then imported into Maptek’s Vulcan™ software (Vulcan) by Cliffs for resource estimation. Sub-blocked model estimates used inverse distance squared (ID2) and length-weighted, 10 ft uncapped composites to estimate KEVs including magnetic iron, weight recovery, and silica in concentrate in a three-search pass approach, using hard boundaries between subunits, ellipsoidal search ranges, and search ellipse orientation informed by geology. Average density values were assigned by lithological unit.

Mineral Resources were classified in accordance with the definitions for Mineral Resources in S-K 1300. Blocks were classified as Measured, Indicated, or Inferred using distance-based and qualitative criterion. Cliffs classifies the Mineral Resources based primarily on drill hole spacing and influenced by geologic continuity, ranges of economic criteria, and reconciliation. Some post-processing is undertaken to ensure spatial consistency and remove isolated and fringe blocks. The resource area is limited by a polygon and subsequent pit shell based on practical mining limits. A block of ore is classified as Measured if the distance to the nearest drill hole is within 400 ft and estimated with the pass 1 estimate. If the nearest drill hole is between 400 ft and 800 ft and estimated in the pass 2 estimate, it is classified as Indicated. All remaining blocks are classified as Inferred.

Estimates were validated using standard industry techniques including statistical comparisons with composite samples and parallel nearest neighbor (NN) estimates, swath plots, as well as visual reviews in cross-section and plan completed for both deposits. A visual review, comparing blocks to drill holes completed after the block modeling work, was performed to ensure general lithologic and analytical conformance.

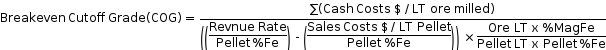

To ensure that all Mineral Resource statements satisfy the “reasonable prospects for eventual economic extraction” requirement, Mineral Resources were constrained within an open-pit shell, prepared by Cliffs and based on a US$90/LT pellet value and a wet 62.5% Fe flux pellet. The Minorca Mineral Resource estimate as of December 31, 2021 is summarized in Table 1-5.

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 9

Table 1-5: Summary of Minorca Mineral Resources - December 31, 2021

Cleveland-Cliffs Inc. – Minorca Property

| | | | | | | | | | | | | | |

| Class | Resources | MagFe | Process Recovery | Wet Pellets |

| (MLT) | (%) | (%) | (MLT) |

| Measured | 484.3 | 22.9 | 32.9 | 159.3 |

| Indicated | 317.2 | 22.9 | 32.9 | 104.4 |

| Total Measured + Indicated | 801.5 | 22.9 | 32.9 | 263.7 |

| Inferred | 30.1 | 21.1 | 30.2 | 9.1 |

Notes:

1.Tonnage is reported in long tons equivalent to 2,240 lb.

2.Mineral Resources are reported exclusive of Mineral Reserves and have been rounded to the nearest 100,000.

3.Mineral Resources are estimated at a cut-off grade of 16% crude MagFe.

4.Mineral Resources are estimated using a pellet value of US$90/LT.

5.Waste within the pit is 986.7 MLT at a stripping ratio of 1.23:1 (waste to crude ore).

6.Saleable product reported as a 62.5% Fe content wet flux pellet, shipped product contains 2% moisture.

7.Classification of Mineral Resources is in accordance with the S-K 1300 classification system.

8.Bulk density is assigned based on average readings for each lithology type.

9.Mineral Resources are 100% attributable to Cliffs.

10.Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

11.Numbers may not add due to rounding.

Resource estimates take account of the minimum block size that can be selectively extracted. Mineral Resources are exclusive of Mineral Reserves and are reported at a 16% MagFe cut-off grade. Mining recovery is typically 100%, although the grade tends to be diluted by 1% MagFe due to geological conditions and mining practices.

The SLR QP is of the opinion that, with consideration of the recommendations summarized in this section, any issues relating to all relevant technical and economic factors likely to influence the prospect of economic extraction can be resolved with further work.

1.3.7Mineral Reserve Estimates

Mineral Reserves in this TRS are derived from the current Mineral Resources. The Mineral Reserves are reported as crude ore and are based on open pit mining from the Laurentian, East 1, and East 2 areas. Crude ore is the unconcentrated ore as it leaves the mine at its natural in situ moisture content. The Proven and Probable Mineral Reserves for Minorca are estimated as of December 31, 2021, and summarized in Table 1-6.

Table 1-6: Summary of Minorca Mineral Reserves – December 31, 2021

Cleveland-Cliffs Inc. – Minorca Property

| | | | | | | | | | | | | | |

| Category | Crude Ore Mineral Reserves

(MLT) | Crude Ore MagFe

(%) | Process Recovery

(%) | Wet Pellets

(MLT) |

| Proven | 102.8 | 23.7 | 34.0 | 35.0 |

| Probable | 6.8 | 25.1 | 36.1 | 2.5 |

| Proven & Probable | 109.7 | 23.8 | 34.1 | 37.4 |

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 10

Notes:

1.Tonnage is reported in long tons equivalent to 2,240 pounds and has been rounded to the nearest 100,000.

2.Mineral Reserves are reported at a $90/LT wet flux pellet price free-on-board (FOB) Lake Superior, based on the three-year trailing average of the realized product revenue rate.

3.Mineral Reserves are estimated at a cut-off grade of 16% crude MagFe.

4.Mineral Reserves include mining dilution of 4% and mining extraction losses of 5%.

5.The Mineral Reserve mining stripping ratio (waste units to crude ore units) is at 0.8.

6.Pellets are reported as a 62.5% Fe content wet flux pellet; shipped pellets contain 2.0% moisture.

7.Tonnage estimate based on December 31, 2021 production depletion from surveyed topography on June 28, 2021.

8.Mineral Reserve tons are as delivered to the primary crusher; pellets are as loaded onto lake freighters in Two Harbors, Minnesota.

9.Classification of the Mineral Reserves is in accordance with the S-K 1300 classification system.

10.Mineral Reserves are 100% attributable to Cliffs.

11.Numbers may not add due to rounding.

The three-year (2017 to 2019) trailing average of the realized pellet price is US$98/LT; however, the reserves are evaluated using a pellet price of US$90/LT based on the corporate guidance issued. The pellet value more closely represents the current economic outlook, and the optimization margins still allow for a robust mine-plan. The costs used in this study represent all mining, processing, transportation, and administrative costs including the loading of pellets into lake freighters in Two Harbors, Minnesota.

SLR is not aware of any risk factors associated with, or changes to, any aspects of the modifying factors such as mining, metallurgical, infrastructure, permitting, or other relevant factors that could materially affect the Mineral Reserve estimate.

1.3.8Mining Methods

The Laurentian, East 1, and East 2 areas are mined using conventional surface mining methods. The surface operations include:

•Clearing and grubbing

•Overburden (glacial till) removal

•Drilling and blasting (excluding overburden)

•Loading and haulage

The Mineral Reserve is based on the ongoing, annual-average crude ore production of approximately 8.6 MLT from the Laurentian, East 1, and East 2 pits, producing an average of 2.8 MLT/y of wet flux pellets for domestic consumption.

Mining and processing operations are scheduled 24 hours per day, and the mine production is scheduled to directly feed the processing operations.

The current LOM plan has mining scheduled for 14 years and mines the known Mineral Reserve. The average stripping ratio is 0.8 waste units to 1 crude ore unit (0.8 stripping ratio).

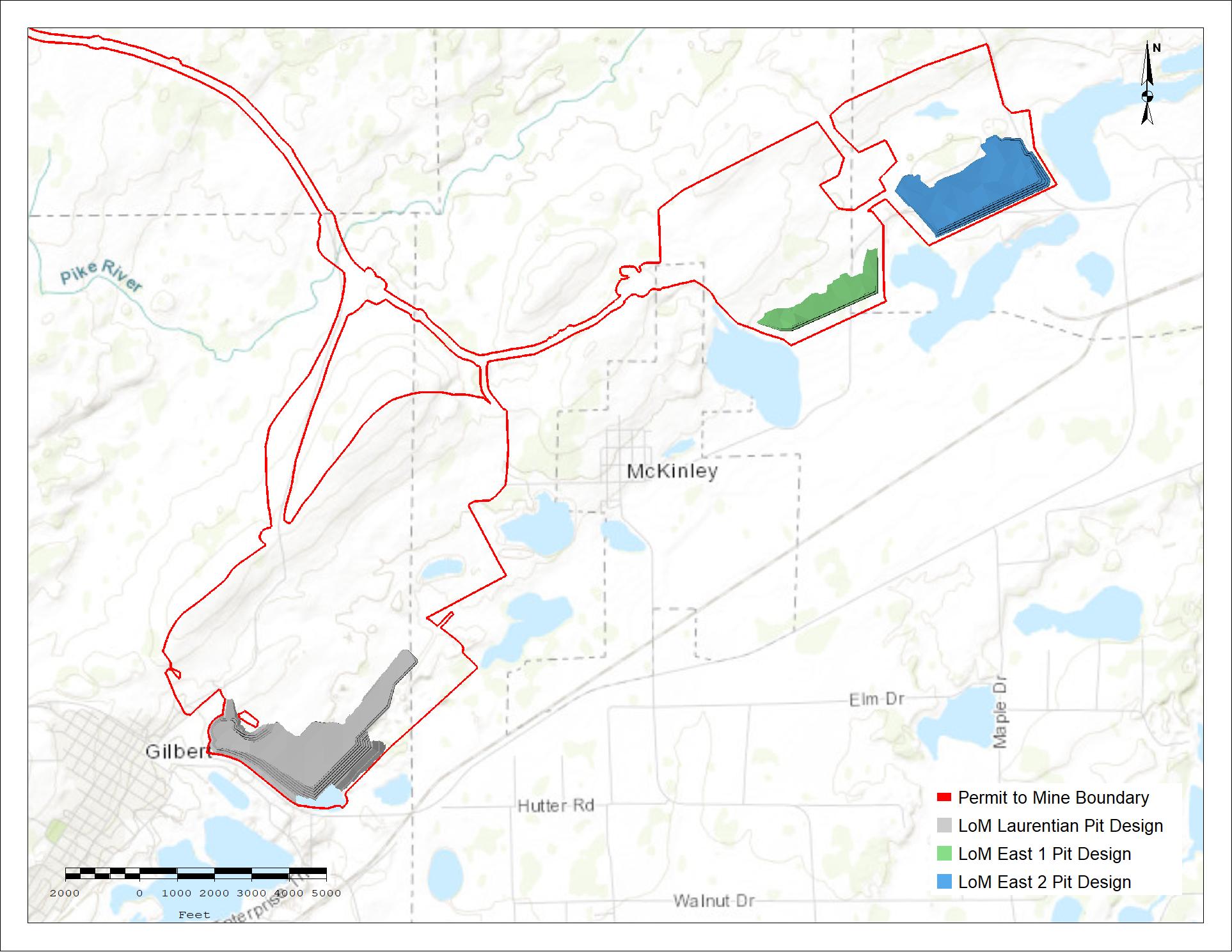

The final Laurentian Pit is approximately 1.2 mi along strike, 0.9 mi wide, and up to 640 ft deep. Crude ore averages approximately 24.4% MagFe. The final East 1 Pit is approximately 0.9 mi along strike, 0.5 mi wide, and up to 310 ft deep. Crude ore within the East 1 Pit averages approximately 22.5% MagFe. The final East 2 Pit is approximately 0.7 mi along strike, 0.4 mi wide, and up to 350 ft deep. The East 2 Pit crude ore contains an average grade of 23.7% MagFe.

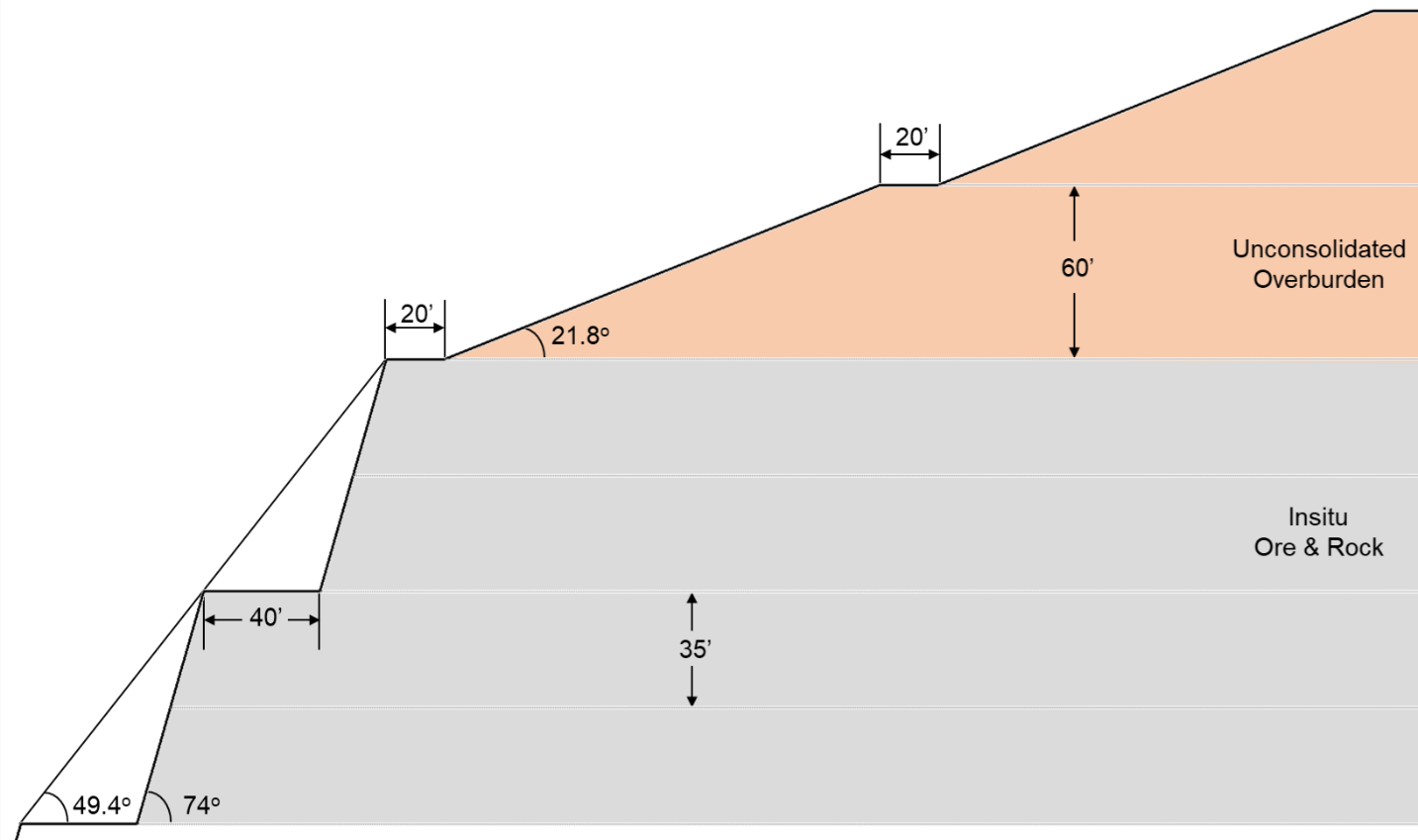

Primary production for all mine pits includes drilling a combination of 12.25 in.- and 16.00 in.-diameter rotary blast holes. Production blast hole depth varies as the pit benches transition from the footwall contact to a full 35 ft bench height. Burden and spacing varies depending on the material being drilled.

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 11

The holes are filled with explosive and blasted. A combination of front-end loaders and hydraulic shovels load the broken material into a mixed fleet of 200 ton- and 240 ton-payload mining trucks for transport from the pit.

The Mine follows strict crude ore blending requirements to ensure that the Plant receives a uniform head grade. The two most important characteristics of the crude ore are magnetic iron content and predicted concentrate silica. Generally, two ore horizons are mined at one time to obtain a satisfactory crude ore blend for the plant. Crude ore is hauled to the crushing facility and either direct tipped to the primary crusher or stockpiled in an area adjacent to the primary crusher. The crude ore stockpiles are used as an additional source for blending and production efficiency.

The major pieces of pit equipment include diesel hydraulic shovels, front-end loaders, haul trucks, drills, bulldozers, and graders. Extensive maintenance facilities are available at the mine site to service the mine equipment.

Mining manpower is at 178 persons, which includes personnel in mine operations, mine maintenance, and mine supervisions and technical services. Mine manpower will increase proportionately with the future forecast increase in haul trucks to meet the LOM production schedule.

1.3.9Processing and Recovery Methods

Minorca’s product is wholly consumed by IH7 and has been in production since 1977. In 1987, Minorca began producing flux pellets instead of standard pellets. In 1992, Minorca constructed a flotation plant to recover silica from the Laurentian Pit ores. No recent metallurgical testing has taken place at Minorca.

Minorca performs diamond drilling to obtain drill core samples to characterize the Mineral Resource associated with the mine plan. Blast hole samples are analyzed in the same manner to validate projected ore grades and develop blending plans. Minorca also conducts plant sampling for process control and product quality reporting for compliance with Standard Product Parameters (SPPs) established by IH7.

Mined ore is directly dumped into a primary gyratory crusher, which crushes the ROM material to P80 6 in. The crushed material is conveyed to a coarse ore stockpile. The coarse ore is reclaimed and conveyed to the secondary crushing plant, where it is crushed by open-circuit, secondary cone crushers and tertiary cone crushers operating in closed circuit with screens to produce a final product with a P100 5/8 in. The crushed product is conveyed and stacked on the fine ore stockpile. The material is reclaimed from the fine ore stockpile and conveyed to the rod mill feed bin.

The concentrator comprises three lines. Ore is drawn from the feed bin into one rod mill per line for coarse grinding. The rod mill discharge flows through wet cobber magnetic separators. The cobber non-magnetic tailings flow to the tailings spiral classifier and then to the tailings thickener. The cobber magnetic concentrate is pumped to three parallel ball mills, followed by eight rougher magnetic separators, and the circuit is closed by hydrocyclones. Cyclone underflow slurry returns to the ball-mill feed, and cyclone overflow slurry is pumped to the hydroseparators. Hydroseparator underflow slurry is pumped to eight fine screens per line and then to final-stage (finisher) magnetic separation. The screen oversize material is conveyed to the ball-mill feed. The product from finisher magnetic separators is thickened in the acid concentrate thickener and pumped to the acid concentrate storage tank. The acid concentrate is then pumped to the fluxed concentrate storage tank, where bentonite and dolomite

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 12

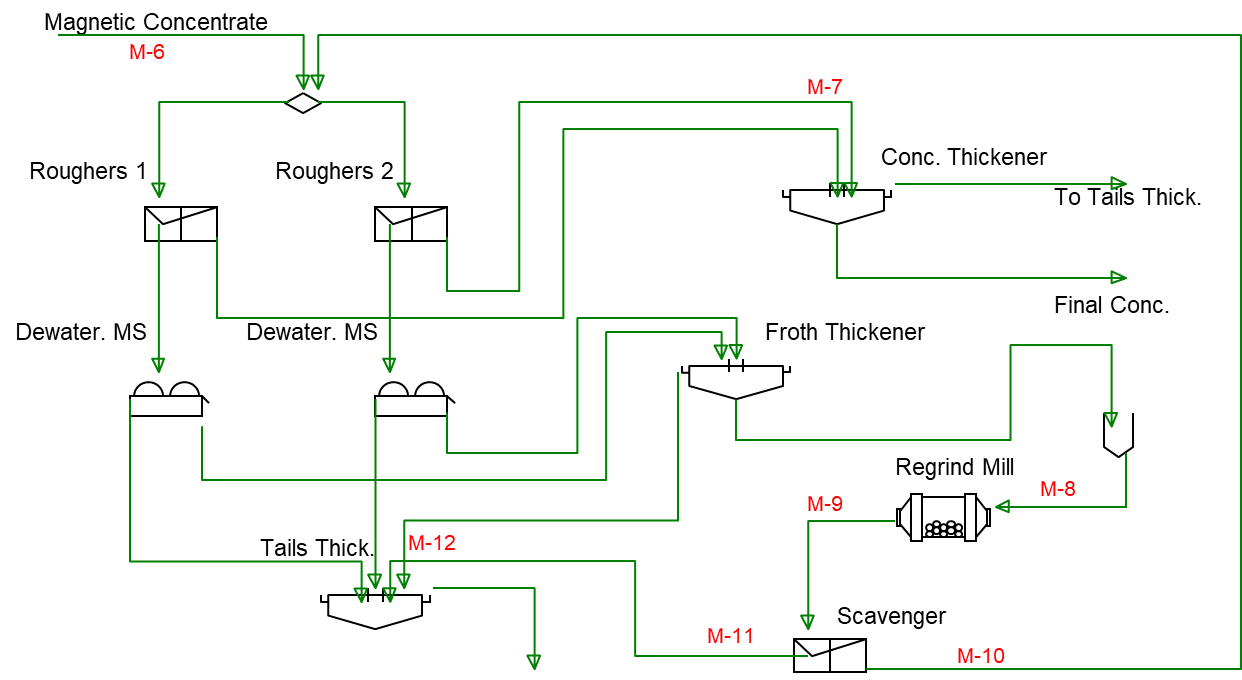

(flux) are added to create flux concentrate. A flotation plant was added to the process to treat ore from the Laurentian Pit, which contains silica that is more difficult to liberate using standard grinding and magnetic separation. Silica particles are floated from the concentrate, and the magnetic iron concentrate reports to the cell underflow, which is directed to the concentrate thickener.

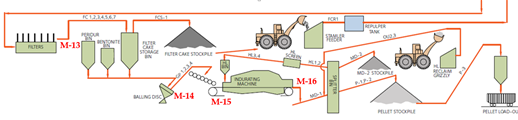

The concentrate is pumped from the concentrate thickener underflow to the acid concentrate storage tank and then transferred to the fluxed concentrate storage tank, where it is mixed with flux slurry. The fluxed concentrate is pumped to the concentrate filters in the pelletizing plant. The concentrate is filtered and agglomerated into green balls (balled) using balling discs. The green balls are sized using roller screens and then conveyed through a straight-grate pelletizing furnace to produce the final hardened flux pellet.

1.3.10Infrastructure

The Property is located in a historically important, iron-producing region of Northeastern Minnesota. All the infrastructure necessary to mine and process significant commercial quantities of iron ore is in place.

Infrastructure items includes:

•Minorca Mine and concentrator facilities near Virginia, Minnesota.

•Power supplied by Minnesota Power.

•Natural gas supplied by Northern Natural Gas from pipelines that connect into the North American distribution system.

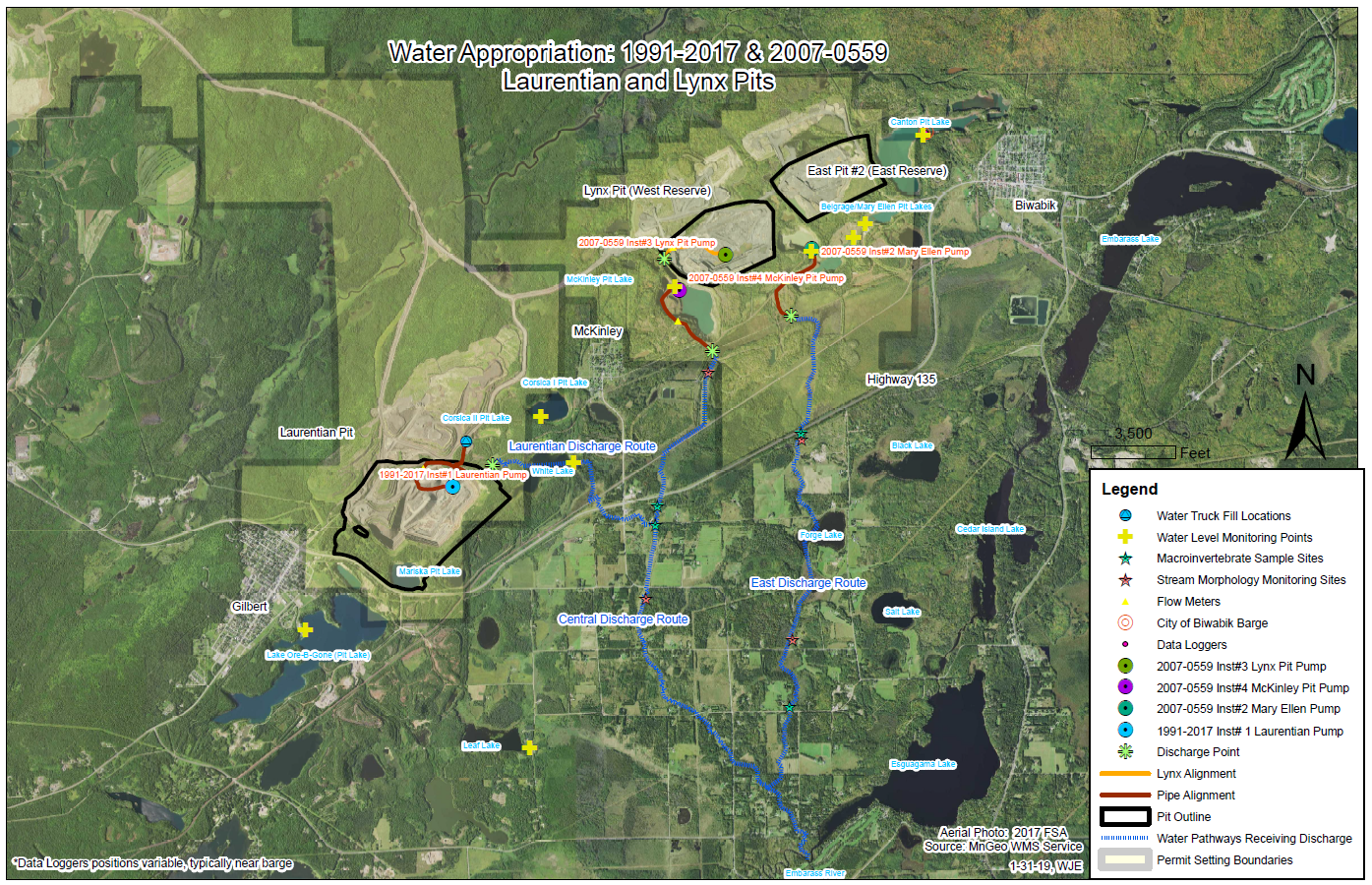

•The Plant uses several water sources for the concentrator, including the clear water pools of the Upland and Minorca In-Pit Tailings Basins (see description below), the Missabe Mountain Pit, the Sauntry/Enterprise Pit, and the Plant Site settling basin. Water can be pumped from the Missabe Mountain Pit into the Sauntry/Enterprise Pit at a rate of 2,000 gpm. Water can be pumped directly to the Plant from the Sauntry/Enterprise (4,000 gpm), Upland Basin (3,800 gpm), the Minorca Basin (5,400 gpm), and the Plant Site Settling Basin (2,800 gpm).

•Paved roads and highways.

•Finished taconite pellets are transported by Canadian National (CN) Railway to the CN port in Two Harbors, Minnesota, approximately 75 mi from the Plant.

•The port is controlled and operated by CN Railway and includes pellet screening, 1.3 MLT of pellet storage and ship loading either directly from rail cars to ship, or from stockpiles to ship. The vessels are 20,000 LT- to 65,000 LT-capacity lakers that transport pellets to steel mills on the Great Lakes.

•Rail yards and workshops are operated by CN Railway.

•Two TSF basins: the Upland Tailings Basin and the Minorca In-pit Tailings Basin. The Upland Tailings Basin is located approximately three miles northeast of the Plant, and the In-pit Tailings Basin is located approximately one mile south-southwest of the Plant. Minorca began using the Upland Tailings Basin as a disposal site for fine tailings in the mid-1970s, and continued to do so until December 2001, at which time Minorca switched to disposing of fine tailings in the Minorca In-pit Tailings Basin. Minorca switched back to the Upland Tailings Basin near the end of 2011, with intermittent disposal into the Minorca In-pit Tailings Basin.

•Accommodations for employees.

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 13

•Local and State infrastructure also includes hospitals, schools, airports, equipment suppliers, fuel suppliers, commercial laboratories, and communication systems.

1.3.11Market Studies

Cliffs is the largest producer of iron ore pellets in North America. It is also the largest flat-rolled steel producer in North America. In 2020, Cliffs acquired two major steelmakers, ArcelorMittal USA (AMUSA), and AK Steel (AK), vertically integrating its legacy iron ore business with steel production and emphasis on the automotive end market.

Cliffs owns or co-owns five active iron ore mines in Minnesota and Michigan. Through the two acquisitions and transformation into a vertically integrated business, the iron ore mines are primarily now a critical source of feedstock for Cliffs’ downstream primary steelmaking operations. Based on its ownership in these mines, Cliffs’ share of annual rated iron ore production capacity is approximately 28.0 million tons, enough to supply its steelmaking operations and not have to rely on outside supply.

The importance of the steel industry in North America and specifically the USA is apparent by the actions of the US federal government in implementing and keeping import restrictions in place. It is important for middle-class job generation and the efficiency of the national supply chain. It is also an industry that supports the nation’s national security by providing products used for US military forces and national infrastructure. Cliffs expects the US government to continue recognizing the importance of this industry and does not see major declines in the production of steel in North America.

Minorca flux pellets are shipped to Cliffs’ steelmaking facilities in the Midwestern USA.

For cash flow projections, Cliffs uses a blended pellet revenue rate of $98/WLT Free on Board (FOB) Mine based on a three-year trailing average for 2017 to 2019. Based on macroeconomic trends, SLR is of the opinion that Cliffs’ pellet prices will remain at least at the current three-year trailing average of $98/WLT or above for the next five years.

1.3.12Environmental Studies, Permitting and Plans, Negotiations, or Agreements with Local Individuals or Groups

CCMMI indicated that it presently has the requisite operating permits for the operation of the Mine and Plant and estimates the mine life to be 14 years. These permits include county, state, and federal permits related to air quality, surface water quality, water appropriation, hazardous waste generation, and wetlands. Minorca does not anticipate any future permitting to realize the mine life; however, multiple permits require renewal. Environmental monitoring and reporting during operations primarily include water and air quality monitoring.

Closure plans and other post-mining plans are required to be prepared at least two years prior to the anticipated closure; however, Cliffs conducts an in-depth review every three years to ensure that the ARO legal liabilities are accurately estimated based on current laws, regulations, facility conditions, and cost to perform services. These cost estimates are conducted in accordance with the Financial Accounting Standards Board (FASB) Accounting Standards Codification (ASC) 410.

With respect to community agreements, Minorca’s mine progression necessitates the drawdown of water levels in the Canton Pit, which is utilized for source water by the city of Biwabik. Minorca entered into a Source Water Change Action Plan with the city of Biwabik (with approval by Minnesota Department of Natural Resources) to transition the city’s water source to the Embarrass Pit in

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 14

2021/2022. Through this agreement, Minorca has invested in new infrastructure to be owned and operated by the city of Biwabik, so the municipality will experience a seamless transition to its new water source (which is of similar quality to the Canton Pit).

1.3.13Capital and Operating Cost Estimates

Productive and sustaining capital expenditure estimates for the remaining LOM are presented in Table 1-7. Starting in 2027, a sustaining capital cost of $4/WLT pellet, or $11.2 million annually, is used in the technical-economic model for an additional $78.4 million for the remaining mine life.

Table 1-7: LOM Capital Costs

Cleveland-Cliffs Inc. – Minorca Property

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Type | Units | Total | 2022 | 2023 | 2024 | 2025 | 2026 | 2027 | 2028-2035 |

| Capital Costs | |

| Total Sustaining | $ millions | 210.2 | 28.2 | 25.5 | 27.8 | 27.1 | 23.2 | 11.2 | 67.2 |

| Pellet Sales | |

| Pellet Sales | MWLT | 37.4 | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 | 20.6 |

| Unit Rates | |

| Total | $/WLT | 5.62 | 10.00 | 9.11 | 9.93 | 9.69 | 8.28 | 4.00 | 3.26 |

Operating costs are based on a full run rate of flux pellet production consistent with what is expected for the LOM. A LOM average operating cost of $85.47/WLT pellet is estimated over the remaining 14 years of the LOM and is shown in Table 1-8.

Table 1-8: LOM Operating Costs

Cleveland-Cliffs Inc. – Minorca Property

| | | | | |

| Description | LOM

($/WLT Pellet) |

| Mining | 16.84 |

| Processing | 45.56 |

| Site Administration | 2.20 |

| Logistics / Dock | 10.78 |

| General / Other | 10.10 |

| Operating Cash Cost | 85.47 |

Cliffs’ forecasted capital and operating costs estimates are derived from annual budgets and historical actuals over the long life of the current operation. According to the American Association of Cost

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 15

Engineers (AACE) International, these estimates would be classified as Class 1 with an accuracy range of -3% to -10% to +3% to +15%.

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 16

2.0INTRODUCTION

SLR International Corporation (SLR) was retained by Cleveland-Cliffs Inc. (Cliffs) to prepare an independent Technical Report Summary (TRS) on the Minorca Property (Minorca or the Property), located in St. Louis County, Northeastern Minnesota, USA. The operator of the Property, Cleveland-Cliffs Minorca Mine Inc. (CCMMI), is a wholly owned subsidiary of Cliffs.

The purpose of this TRS is to disclose year-end (YE) 2021 Mineral Resource and Mineral Reserve estimates for Minorca.

Cliffs is listed on the New York Stock Exchange (NYSE) and currently reports Mineral Reserves of pelletized ore in SEC filings. This TRS conforms to the United States Securities and Exchange Commission’s (SEC) Modernized Property Disclosure Requirements for Mining Registrants as described in Subpart 229.1300 of Regulation S-K, Disclosure by Registrants Engaged in Mining Operations (S-K 1300) and Item 601 (b)(96) Technical Report Summary. SLR visited the property on April 29, 2021.

The Property includes the Laurentian and East Pit mines (collectively the Minorca Mine), between Gilbert and Biwabik, Minnesota and a processing facility (the Plant) in Virginia, Minnesota. The Minorca Mine is a complex of large, operating, open-pit iron mines that produces pellets from a magnetite iron ore regionally known as taconite.

The Property commenced operations in 1976 as an asset of Inland Steel Company (Inland Steel). In 1998, ISPAT International (ISPAT) purchased Inland Steel and in 2004 merged with LNM Holdings and International Steel Group (LNM) to form Mittal Steel, which in 2007 merged with Arcelor to form ArcelorMittal. The Property has been a wholly owned subsidiary of Cliffs since 2020, when Cliffs purchased the US assets of ArcelorMittal, ArcelorMittal USA (AMUSA).

The open-pit operation at Minorca has a mining rate of approximately 8.6 million long tons (MLT) of ore per year and produces 2.8 MLT of wet flux iron ore pellets, which are shipped by freighter via the Great Lakes to Cliffs’ steel mill facilities in the Midwestern USA.

2.1Site Visits

SLR Qualified Persons (QPs) visited the Property on April 29, 2021. During the site visit, the SLR team all toured the tailings basin, plant laboratory, concentrator and pelletizing facilities, including rail pellet load-out site, and the mine offices and operational areas. The SLR geologist also reviewed drill core logging and sampling procedures, as well as reviewed modeling procedures with the Cliffs mine geologist staff.

2.2Sources of Information

Technical documents and reports on the Property were obtained from Cliffs’ personnel. During the preparation of this TRS, discussions were held with personnel from Cliffs:

•Kurt Gitzlaff, Director - Mine Engineering, Cliffs Technical Group (CTG)

•Michael Orobona, Principal Geologist, CTG

•Michael Koop, Lead Mine Engineer, CTG

•Garret Eliason, Senior Geologist, CTG

•Scott Gischia, Director - Environmental Compliance

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 17

•Dean Korri, Director - Basin and Civil Engineering

•Tushar Mondhe, Senior Manager - Operations and Capital Finance

•Eric Krause, Manager – Mine/Crushing

•Bill Ellingson, Senior Engineer – Mine/Crushing

•Adam Sersha, Manager – Concentrator/Pellet Plant

•Jaime Johnson, Manager – Environmental

This TRS was prepared by SLR QPs. The documentation reviewed, and other sources of information, are listed at the end of this report in Section 24.0, References.

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 18

2.3List of Abbreviations

The U.S. System for weights and units has been used throughout this report. Tons are reported in long tons (LT) of 2,240 lb unless otherwise noted. All currency in this report is US dollars (US$ or $) unless otherwise noted.

Abbreviations and acronyms used in this TRS are listed below.

| | | | | | | | | | | |

| Unit Abbreviation | Definition | Unit Abbreviation | Definition |

| a | annum | LT/d | long tons per day |

| A | ampere | LT/h | long tons per hour |

| acfm | actual cubic feet per minute | M | mega (million); molar |

| bbl | barrels | Ma | one million years |

| Btu | British thermal units | MBtu | thousand British thermal units |

| d | day | MCF | million cubic feet |

°F | degree Fahrenheit | MCF/h | million cubic feet per hour |

| fasl | feet above sea level | mi | mile |

| ft | foot | min | minute |

ft2 | square foot | MLT/y | million long tons per year |

ft3 | cubic foot | MPa | megapascal |

| ft/s | foot per second | mph | miles per hour |

| g | gram | MVA | megavolt-amperes |

| G | giga (billion) | MW | megawatt |

| Ga | one billion years | MWh | megawatt-hour |

| gal | gallon | MWLT | million wet long tons |

| gal/d | gallon per day | oz | Troy ounce (31.1035g) |

g/cm3 | grams per cubic centimeter | oz/ton | ounce per short ton |

| g/L | gram per liter | ppb | part per billion |

| g/y | gallon per year | ppm | part per million |

| gpm | gallons per minute | psia | pound per square inch absolute |

| hp | horsepower | psig | pound per square inch gauge |

| h | hour | rpm | revolutions per minute |

| Hz | hertz | RL | relative elevation |

| in. | inch | s | second |

in2 | square inch | ton | short ton |

| J | joule | stpa | short ton per year |

| k | kilo (thousand) | stpd | short ton per day |

kg/m3 | Kilogram per cubic meter | t | metric tonne |

| kVA | kilovolt-amperes | US$ | United States dollar |

| kW | kilowatt | V | volt |

| kWh | kilowatt-hour | W | watt |

| kWLT | thousand wet long tons | wt% | weight percent |

| L | liter | WLT | Wet long ton |

| lb | pound | y | year |

| LT | long or gross ton equivalent to 2,240 pounds | yd3 | cubic yard |

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 19

| | | | | |

| Acronym | Definition |

| AACE | American Association of Cost Engineers |

| AK | AK Steel |

| AMUSA | ArcelorMittal USA |

| ANSI | American National Standards Institute |

| ARO | asset retirement obligation |

| ASC | Accounting Standards Codification |

| ASQ | American Society for Quality |

| ASTM | American Society for Testing and Materials |

| BF | blast furnace |

| BFA | bench face angle |

| BH | bench height |

| BIF | banded iron formation |

| BLS | United States Bureau of Labor Statistics |

| CBOD5 | carbonaceous biochemical oxygen demand, 5 day test |

| CCD | counter-current decantation |

| CCP | Conceptual Closure Plan |

| CERCLA | Comprehensive Environmental Response, Compensation, and Liability Act |

| CFR | Cost and Freight |

| CN | Canadian National Railway |

| COA | certificates of analysis |

| CRIRSCO | Committee for Mineral Reserves International Reporting Standards |

| D&A | depreciation and amortization |

| DCF | discounted cash flow |

| DD | diamond core drilling |

| DMTT | Davis Magnetic Tube Test |

| DRI | direct reduced iron |

| DSO | direct-shipping iron ore |

| DT | Davis Tube |

| EAF | electric arc furnace |

| EAP | Emergency Action Plan |

| EIS | Environmental Impact Statement |

| EMP | Environmental Management Plan |

| EMS | environmental management system |

| EPA | United States Environmental Protection Agency |

| EPRT | External Peer Review Team |

| ESOP | Environmental Standard Operating Procedures |

| EOR | Engineer of Record |

| FASB | Financial Accounting Standards Board |

| FEL | front-end loader |

| FOB | Free on Board |

| GHG | greenhouse gas |

| GIM | Geoscientific Information Management |

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 20

| | | | | |

| Acronym | Definition |

| GPS | global positioning system |

| GSI | Geological Strength Index |

| GSSI | General Security Services Corporation |

| HBI | hot-briquetted iron |

| HRC | hot-rolled coil |

| ICP | induced couple plasma |

ID2 | Inverse distance squared |

ID3 | Inverse distance cubed |

| IF | iron formation |

| ICFM | inlet air capacity |

| IIMA | International Iron Metallics Association |

| IRA | inter-ramp angle |

| IRR | Internal Rate of Return |

| ISO | International Standards Organization |

| KEV | key economic variables |

| LG | Lerchs-Grossmann |

| LiDAR | light imaging, detection, and ranging |

| LMF | Laurentian Mixed Forest |

| LOM | life of mine |

| MAC | Mining Association of Canada |

| MDH | Minnesota Department of Health |

| MDNR | Minnesota Department of Natural Resources |

| MLT | million long tons |

| MPCA | Minnesota Pollution Control Agency |

| MPUC | Minnesota Public Utilities Commission |

| MR | moving range |

| MRCC | Midwestern Regional Climate Center |

| MSHA | Mine Safety and Health Administration |

| NESHAP | National Emission Standards for Hazardous Air Pollutants |

| NGO | non-governmental organization |

| NGVD | National Geodetic Vertical Datum |

| NNG | Northern Natural Gas |

| NOAA | National Oceanic and Atmospheric Administration |

| NOLA | Nuclear On-Line Analyzer |

| NPDES | National Pollution Discharge Elimination System |

| NPV | Net Present Value |

| NRRI | Natural Resources Research Institute |

| OMS | Operations, Maintenance and Surveillance |

| PLC | Programmable Logic Controller |

| PMF | probable maximum flood |

| QA/QC | quality assurance and quality control |

| QP | Qualified Person |

| RC | rotary circulation drilling |

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 21

| | | | | |

| Acronym | Definition |

| RCRA | Resource Conservation and Recovery Act |

| ROM | run of mine |

| RQD | Rock Quality Designation |

| RTR | risk and technology revie |

| SDS | State Disposal System |

| SEC | United States Securities and Exchange Commission |

| SG | specific gravity |

| SMU | selective mining unit |

| SQL | Structured Query Language |

| SPC | statistical process control |

| TMDL | Total Maximum Daily Load |

| TRS | Technical Report Summary |

| TSF | tailings storage facility |

| TSP | total suspended particulates |

| UCS | uniaxial compressive strength |

| USACE | United States Army Corps of Engineers |

| USGS | United States Geological Survey |

| VIMS | vehicle information management system |

| XRF | x-ray fluorescence |

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 22

3.0PROPERTY DESCRIPTION

3.1Location

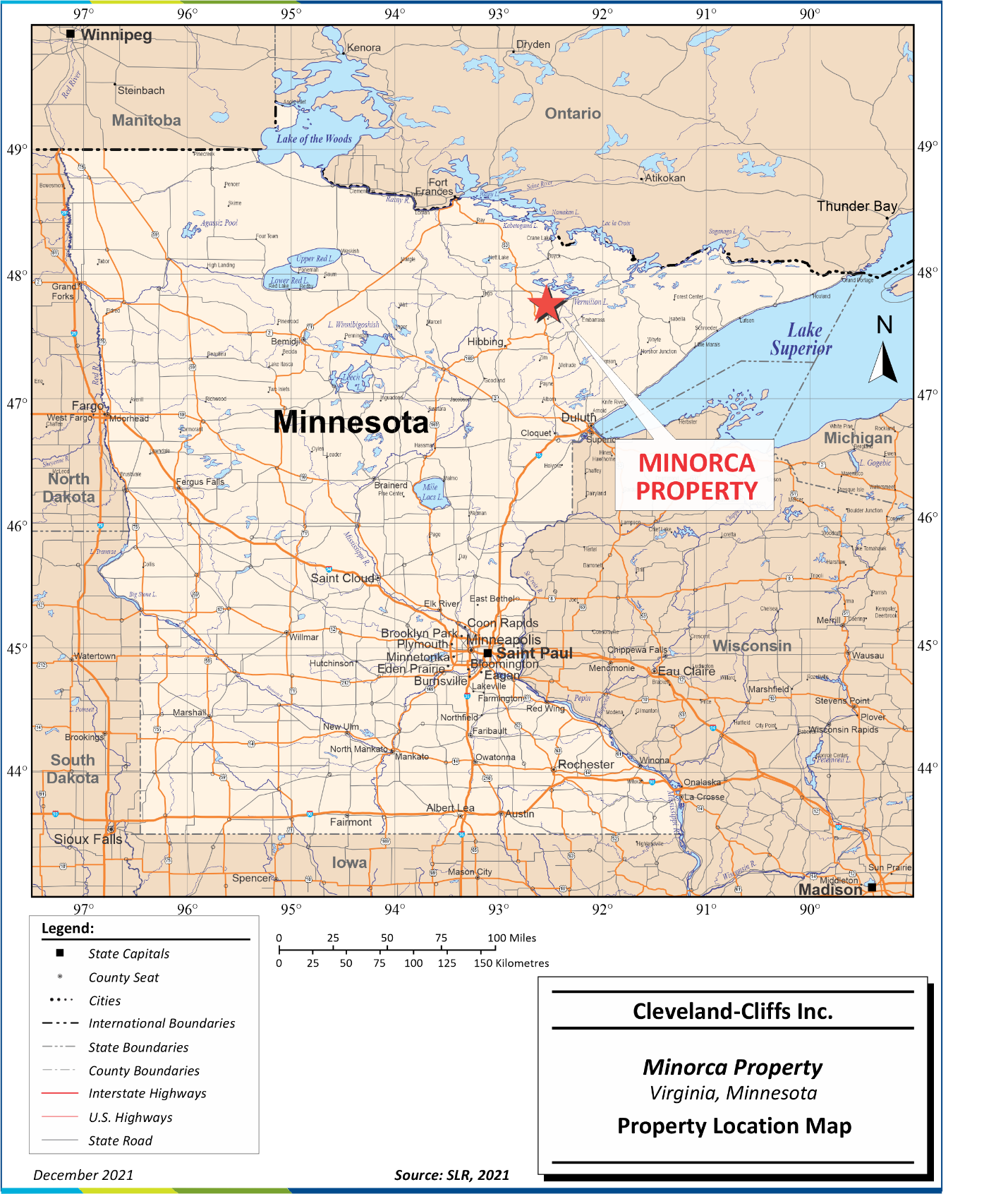

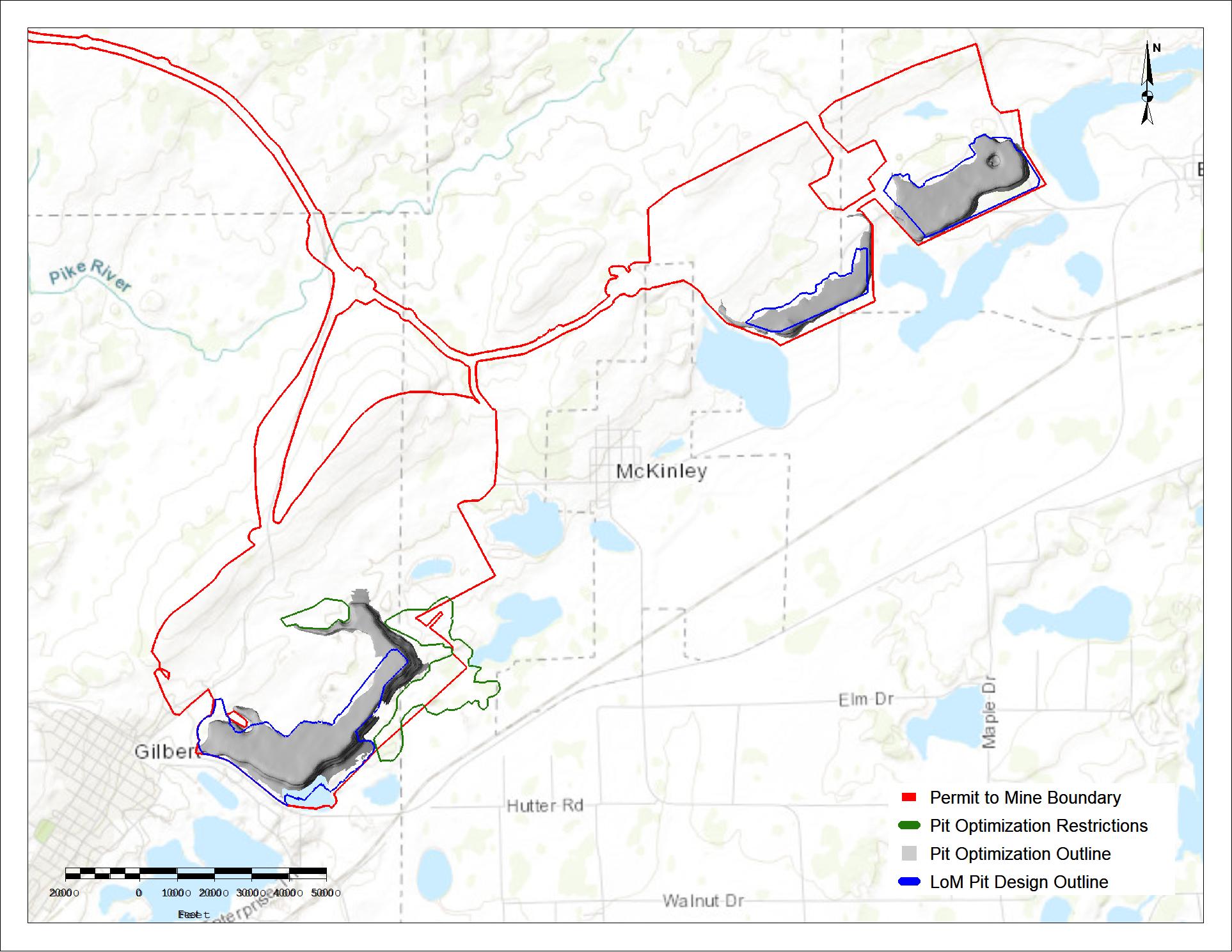

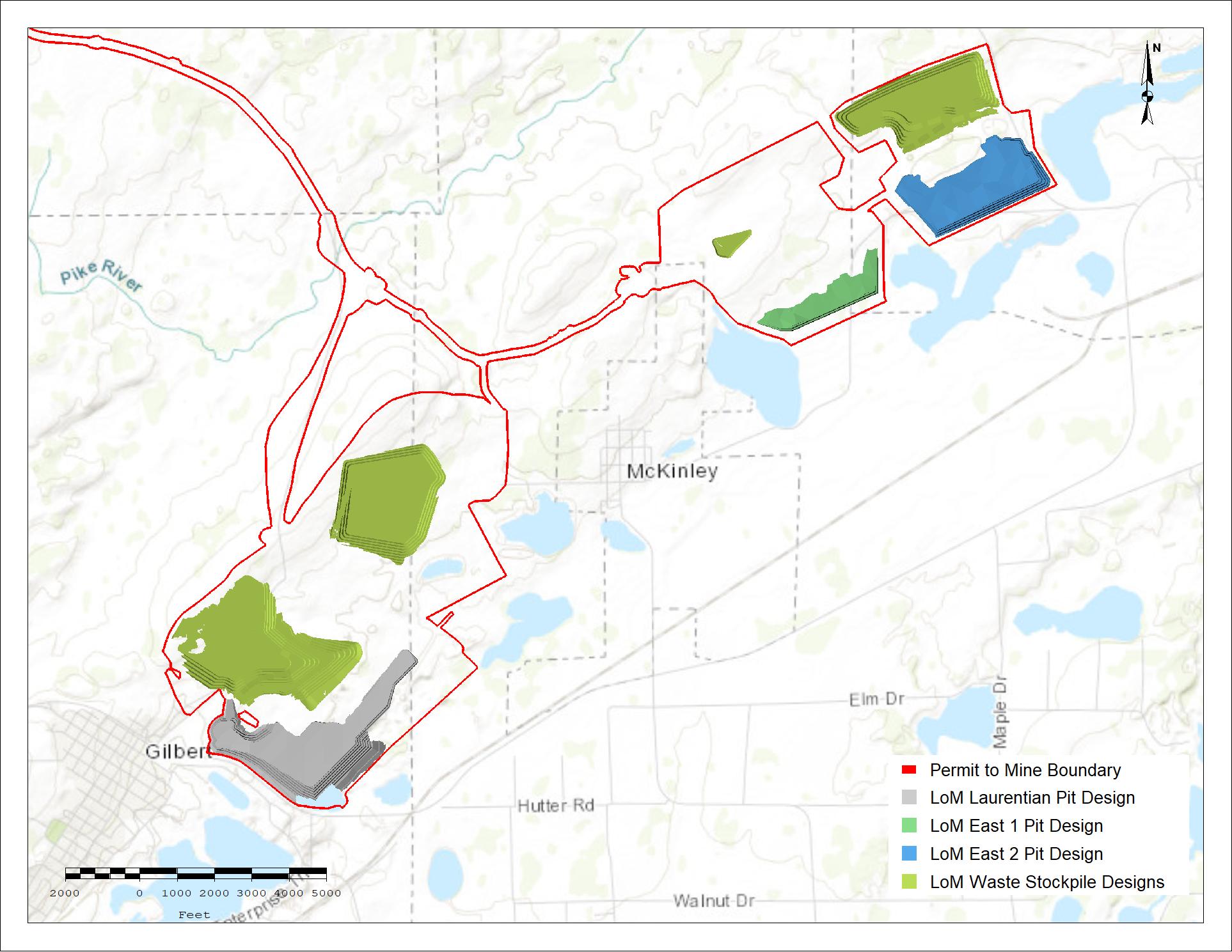

The Property is located in St. Louis County, Northeastern Minnesota, USA, on the Mesabi Iron Range, between the towns of Virginia, Gilbert, and Biwabik, Minnesota. The Laurentian Pit is located near the city of Gilbert, Minnesota at latitude 47°30'0"N and longitude 92°26’30"W, East 1 (also termed Lynx) Pit is located at latitude 47°31'30"N and longitude 92°23’30"W, and East 2 (also termed Whiskey) Pit is located just west of the city of Biwabik at latitude 47°32'0"N and longitude 92°22’30"W. The Minorca Plant is located approximately seven miles to the northeast near the town of Virginia, Minnesota at latitude 47°33'30"N and longitude 92°31.5'30"W. Figure 3-1 presents the locations of the Minorca Mine and Plant.

3.2Land Tenure

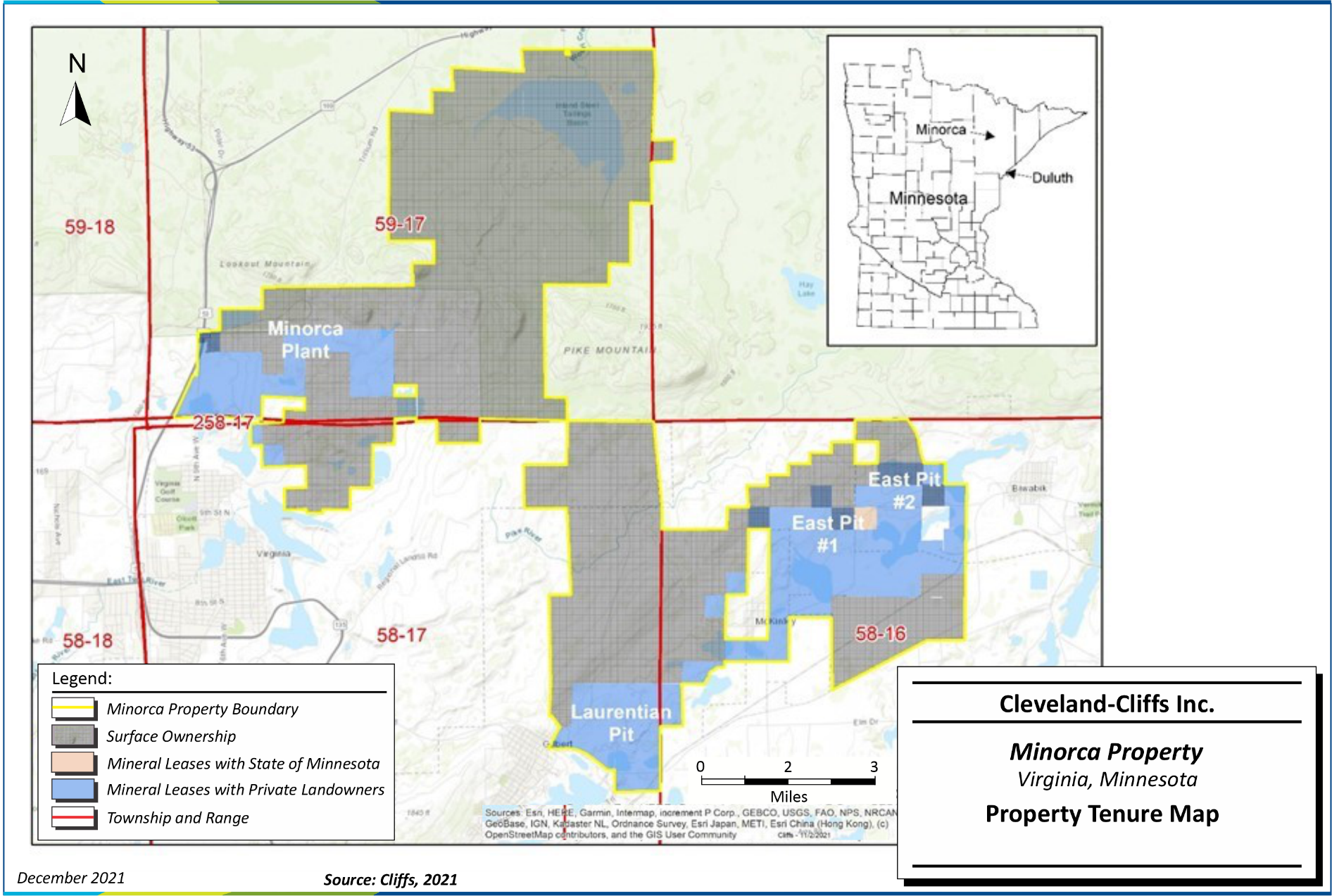

The Minorca Property Boundary comprises approximately 16,825 acres in a combination of mineral leases, surface leases, and owned property.

3.2.1Mineral Rights

The Property consists of approximately 3,135 acres of mineral leases granted by private landowners and the State of Minnesota as summarized in Table 3-1 and illustrated in Figure 3-2. Mineral leases generally include surface mining rights. Where the mineral leases do not include surface mining rights, Minorca controls the surface through ownership or surface leases with the owner of the surface. Approximately 282 acres of owned property is associated with the mineral lease acreage.

Minorca mineral leases expire between 2035 and 2056, with the State of Minnesota mineral leases expiring in 2035. In order to maintain the mineral leases until expiration, Minorca must continue to make minimum prepaid royalty payments each quarter and pay property taxes. When mining occurs, a royalty is due per long ton of crude ore mined, or long ton of pellets produced from the crude ore mined, and is payable to the respective lessors quarterly. Royalty rates per long ton fluctuate based on industry and economic indexes. Minimum prepaid royalty payments may be credited against royalties due when mining occurs. Specific terms and provisions of the mineral leases are confidential.

There are quarterly royalty payments made on the Minorca mine mineral leases to multiple third parties. The details of the royalties are confidential between Minorca and the lessors.

Table 3-1: Mineral Tenures and Rights

Cleveland-Cliffs Inc. – Minorca Property

| | | | | | | | | | | | | | |

| Lease Name | Owners’ Name | Start Date | Expiration Date | Compliance Status |

| Allen-Ulland Lease | Multiple parties | 1/1/1981 | 1/1/2056 | YES |

| Beckman Lease | Susan Beckman | 4/24/2012 | 12/31/2040 | YES |

| Laurentian - Red Cross | Laurentian LLC and American Red Cross | 1/1/1997 | 12/31/2040 | YES |

| Manthey et al. | | | 12/31/2040 | |

| McClintock-Kirby | | | 5/28/2056 | |

Cleveland-Cliffs Inc. | Minorca Mine, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 23

| | | | | | | | | | | | | | |

| Lease Name | Owners’ Name | Start Date | Expiration Date | Compliance Status |

| Ordean et al. | Cowen et al. | 6/1/1968 | 6/1/2043 | YES |

| Penobscot et al. Lease | Multiple Owners | 1/1/1989 | 12/31/2041 | YES |

| Rendrag | Rendrag, Inc.; DRM Minerals Corp.; KMK Dunka, Inc.; Optimal Mining, Inc.; Taconite Lessors | 7/1/2010 | 12/31/2040 | YES |

| RGGS 1966 | | | 12/19/2041 | |

| RGGS 1994 | USX Corporation (now U.S. Steel) | 7/1/1994 | 12/31/2043 | YES |

| RGGS 2005 | RGGS Land & Materials Ltd. | 10/1/2005 | 10/1/2035 | YES |

| Sidney Mine Lease | Wilber et al. | 10/1/1967 | 10/1/2042 | YES |

| State T-5090-N | State of Minnesota | 11/9/2008 | 12/31/2035 | YES |

| State T-5104-N | State of Minnesota | 1/1/2013 | 12/31/2035 | YES |

| Wayland Lease | Wayland Land LLC | 1/1/2007 | 12/31/2036 | YES |

| Wiese Lease | Ferdinand J. Wiese Trust | 11/7/2011 | 12/31/2040 | YES |

3.2.2Surface Rights

The Property consists of approximately 13,690 acres of owned property (282 acres associated with mineral leases) in and around the Property as illustrated in Figure 3-2. To maintain ownership, the property taxes must be paid to St. Louis County, Minnesota.

Cleveland-Cliffs Inc. | Minorca Mine, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 24

Figure 3-1: Property Location Map

Cleveland-Cliffs Inc. | Minorca Mine, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 25

Figure 3-2: Property Tenure Map

Cleveland-Cliffs Inc. | Minorca Mine, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 26

3.3Encumbrances

CCMMI grants leases, licenses, and easements for various purposes, including miscellaneous community land uses, utility infrastructure, and other third-party uses that encumber the Property but do not inhibit operations. Certain assets of CCMMI serve as collateral as part of Cliffs’ asset-based lending (ABL) facility. Cliffs has outstanding standby letters of credit, which were issued to back certain obligations of CCMMI, including certain permits and certain tailings basin projects. Additionally, CCMMI has and may continue to enter into lease agreements for necessary equipment used in the operations of the mine.

3.4Royalties

Reference section 3.2 for royalty information. No overriding royalty agreements are in place.

3.5Other Significant Factors and Risks

No additional significant factors or risks are known.

SLR is not aware of any environmental liabilities on the Property. Cliffs has all required permits to conduct the proposed work on the Property. SLR is not aware of any other significant factors and risks that may affect access, title, or the right or ability to perform the proposed work program on the Property.

Cleveland-Cliffs Inc. | Minorca Mine, SLR Project No: 138.02467.00001

Technical Report Summary - February 7, 2022 27

4.0ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY

4.1Accessibility

The Property is easily accessed via paved roads from Virginia, Minnesota, approximately one mile to the west, or the towns of Gilbert and Biwabik, Minnesota, approximately one mile to the west and east, respectively. A rail line operated by Canadian National Railway (CN) extends from the Minorca processing facility to the port of Two Harbors, Minnesota, a major port city on Lake Superior, which is 75 mi southeast of the Property. Duluth, Minnesota is also 69 mi southeast of Virginia via US Highway 53 and 27 mi southwest of Two Harbors via MN Highway 61. Duluth also has a regional airport with several flights daily to major hubs in Minneapolis, Minnesota and Chicago, Illinois. Refer to Section 3.0 of this TRS and Figure 3-2 for the location of roads providing access to the Property.

4.2Climate

The climate in Northern Minnesota ranges from mild in the summer to winter extremes. The annual average temperature is 36.9oF. The annual average high temperature is 48.6°F, whereas the annual average low temperature is 25.1°F. By month, July is on average the hottest month (77°F), with January being the coldest (-4°F) (National Oceanic and Atmospheric Administration [NOAA], 1991-2020). Table 4-1 lists complete climate data for the area for 1991 to 2020.

Table 4-1: Northern Minnesota Climate Data (1991-2020)

Cleveland-Cliffs Inc. – Minorca Property

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Month | Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | Year |

| Average high (°F) | 16.9 | 22.5 | 35.4 | 49.5 | 63.4 | 72.2 | 76.7 | 74.9 | 65.7 | 50.8 | 34.3 | 21.4 | 48.6 |

| Daily mean (°F) | 6.2 | 10.5 | 23.8 | 37.1 | 49.5 | 58.9 | 63.5 | 61.6 | 53 | 40.2 | 25.6 | 12.3 | 36.9 |

| Average low (°F) | −4.4 | −1.4 | 12.2 | 24.8 | 35.7 | 45.7 | 50.3 | 48.3 | 40.3 | 29.7 | 16.9 | 3.1 | 25.1 |

| Precipitation (inches) | 0.51 | 0.53 | 0.91 | 1.61 | 2.76 | 4.36 | 3.85 | 3.09 | 3.06 | 2.35 | 1.09 | 0.64 | 24.76 |

| Snowfall (inches) | 15 | 7.1 | 7.8 | 3.7 | 0 | 0 | 0 | 0 | 0 | 1.2 | 13.2 | 12.3 | 60.3 |

Source: NOAA, 2021

Precipitation as rain in the Northern Minnesota area ranges from less than one inch in December, January, and February, to approximately three to four inches per month during the summer, averaging approximately 25 in. annually. Annual snowfalls average 60 in. during November through March. Approximately half of the precipitation occurs during the summer months.

The Property is in production year-round.

4.3Local Resources

Labor is readily available in the Property area. Medical facilities with trauma centers are located in the cities of Virginia, Hibbing, and Duluth, Minnesota. Table 4-2 presents a list of the major population centers and their distance by road to the Property entrance near Virginia.

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

NI 43-101 Technical Report - February 7, 2022 28

Table 4-2: Near-by Population Centers

Cleveland-Cliffs Inc. – Minorca Property

| | | | | | | | | | | |

| City/Town | Medical Center | Population 2010 Census | Mileage to Property |

| Gilbert, MN | n/a | 1,799 | 10 |

| Eveleth, MN | n/a | 3,718 | 11 |

| Virginia, MN | Level IV | 8,712 | 4 |

| Duluth, MN | Level I and II | 85,884 | 69 |

| Hibbing, MN | Level III | 16,361 | 27 |

Source: US Census Bureau, Google Maps

The Minorca operation employs 362 personnel as of Q4 2021 who live in the surrounding cities of Virginia, Eveleth, Gilbert, and Hibbing. Personnel also commute from Duluth and the Iron Range. St. Louis County has an estimated population of 200,000 people.

4.4Infrastructure

The Property is located in a historically important, iron-producing region of Northeastern Minnesota. All infrastructure necessary to mine and process significant commercial quantities of iron ore is currently in place. Infrastructure items include high-voltage electrical supplies, natural gas pipelines that connect to the North American distribution system, water sources, paved roads and highways, railroads for transporting run of mine (ROM) crude ore and finished products, port facilities that connect to the Great Lakes, and accommodations for employees. Local and State infrastructure also includes hospitals, schools, airports, equipment suppliers, fuel suppliers, commercial laboratories, and communication systems. Additional information regarding Minorca supporting infrastructure can be found in Section 15.0 of this TRS.

4.5Physiography

The Property is located in St. Louis County, Northeastern Minnesota at an elevation of approximately 1,700 fasl. The generally gentle topography in the area is characterized by hummocky hills and long, gentle moraines, remnants of glacial ingress and egress. The landscape ranges from semi-rugged, lake-dotted terrain with thin glacial deposits over bedrock, to hummocky or undulating plains with deep glacial drift, to large, flat, poorly drained peat lands. Topography includes rolling till plains, moraines, and flat outwash plains formed by the Rainy Lobe glacier. The Giants Range, a narrow bedrock ridge rising 200 ft to 400 ft above the surrounding area, is the most striking feature on the Property. Bedrock is locally exposed near terminal moraines, but is generally rare.

The Minnesota Department of Natural Resources (MDNR) characterizes the area as being within the Laurentian Mixed Forest (LMF) Province, which covers over 23 million acres of Northeastern Minnesota. In Minnesota, the LMF is characterized by broad areas of conifer forest, mixed hardwood and conifer forests, and conifer bogs and swamps. Vegetation is a mixture of deciduous and coniferous trees. White pine-red pine forest and jack pine barrens are common on outwash plains. Aspen-birch forest and mixed hardwood-pine forest are present on moraines and till plains. Wetland vegetation includes conifer bogs, lowland grasses, and swamps. Prior to settlement, the area consisted of forest communities dominated by white pine, red pine, balsam fir, white spruce, and aspen-birch.

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

NI 43-101 Technical Report - February 7, 2022 29

Brown glacial sediments form the parent material for much of the soils in the area. Soils are varied and range from medium to coarse textures. Soils are formed in sandy to fine-loamy glacial till and outwash sand. Soils on the Nashwauk Moraine have a loamy cap with dense basal till below at depths of 20 in. to 40 in. These soils are classified as boralfs (cold, well-drained soils developed under forest vegetation) (MDNR, 2011).

Cleveland-Cliffs Inc. | Minorca Property, SLR Project No: 138.02467.00001

NI 43-101 Technical Report - February 7, 2022 30

5.0HISTORY

5.1Prior Ownership

The Property has been owned by several companies since it started operation in 1977. The ownership changes and milestones in the development of the Property are as follows:

•1974 Construction began on the Minorca taconite plant by Inland Steel.

•1977 Mining began in the Minorca Pit.

•1987 Commenced production of flux pellets.

•1992 Construction of float plant for silica reduction of the new Jones and Laughlin Steel Company (J&L) Reserve (the Laurentian, East, and Central deposits).

•1992 Mining began in the Laurentian Pit.

•1998 Minorca was purchased by ISPAT.

•2005 ISPAT International merged with LNM to form Mittal Steel.

•2007 Mittal Steel merged with Arcelor to form ArcelorMittal.

•2008 Mining began in the East Pit.

•2017 Minorca total production of iron ore pellets reaches 100,000,000 tons.

•2019 Mining began in the Laurentian Western Pushback.

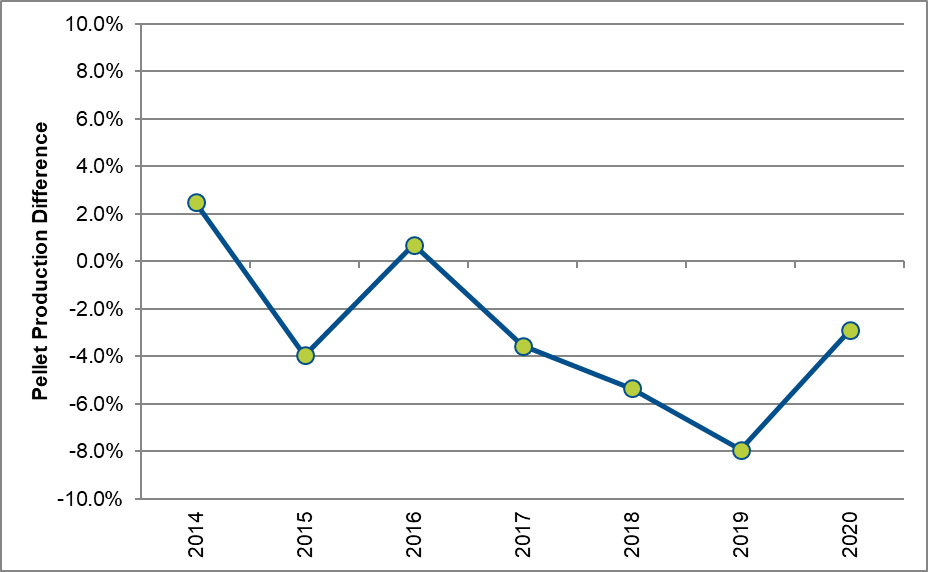

•2020 Cliffs purchased the US assets of ArcelorMittal, AMUSA, and now owns Minorca.